Get the free Used Lube Oil Re-refining

Get, Create, Make and Sign used lube oil re-refining

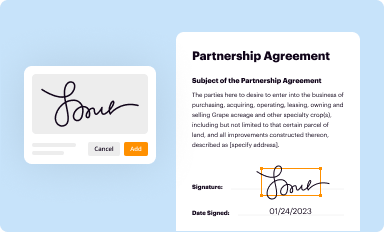

How to edit used lube oil re-refining online

Uncompromising security for your PDF editing and eSignature needs

How to fill out used lube oil re-refining

How to fill out used lube oil re-refining

Who needs used lube oil re-refining?

Used lube oil re-refining form: A comprehensive how-to guide

Understanding used lube oil re-refining

Used lube oil re-refining is a critical process focusing on the recycling and rejuvenation of spent lubricating oils. This procedure transforms waste oil into a usable, high-quality product, significantly reducing environmental impact and waste management issues. In essence, re-refining involves a series of technologies that recover valuable base oil from used lubricants, ensuring it can be reused in vehicles and machinery.

The significance of used lube oil re-refining cannot be understated. With millions of gallons of oil discarded each year, re-refining emerges as a more sustainable alternative to traditional disposal methods, such as landfilling or incineration. By processing used oil, we conserve natural resources, reduce the carbon footprint associated with producing virgin oil, and foster a more sustainable environment.

The used lube oil re-refining process

The re-refining process consists of several precise steps that ensure the effective conversion of used oil back into a usable form. Initially, used lube oil is collected and transported to a recycling facility. It's crucial that this step is performed efficiently, as the quality of the collected oil directly impacts the re-refining efficacy. Once at the facility, the oil undergoes pretreatment processes, including filtration and separation. Here, physical contaminants such as dirt and metal particles are removed, and water is separated from the oil.

Following pretreatment, distillation methods are employed to further refine the oil. Vacuum distillation is a common method, as it allows for the separation of lighter and heavier fractions of oil at lower temperatures, thereby preserving the quality of the oil. Once separated, the various fractions are treated to remove any residual contaminants, utilizing techniques such as hydrotreatment or acid treatment. The result is a high-quality re-refined base oil that meets industry standards and can be reused in lubricant formulations.

Key considerations for effective re-refining

To optimize the used lube oil re-refining process, it is vital to adopt best practices that maximize yield and efficiency. This includes maintaining a clean facility to avoid contamination during processing and ensuring that collection and transportation channels are robust and efficient. Regular monitoring of oil characteristics during various stages of the process is also necessary to adapt methods as required.

Common challenges in the re-refining process can include fluctuating quality of collected oil, regulatory hurdles, and operational inefficiencies. One effective way to overcome these obstacles is by employing advanced analytics and product quality measurements. Investing in modern technologies and employee training can help streamline operations and consistently deliver high-quality re-refined oil.

Cost analysis of used lube oil re-refining

Understanding the costs involved in used lube oil re-refining is essential for effective financial management. Initial setup costs can be considerable, depending on the technology and equipment used, while operational expenses will encompass labor, utilities, and maintenance. Ultimately, a well-designed facility can offset these costs through the substantial savings achieved when compared to the production of virgin oil.

Several factors can influence the overall costs of re-refining. Supply chain dynamics, such as the availability and price fluctuations of used oil, can significantly impact operational budgeting. Additionally, compliance with environmental regulations often requires investments in technology and workforce training. Having a thorough understanding of these factors allows businesses in the re-refining sector to make informed financial decisions.

Strategies for cost control in re-refining

For businesses looking to tighten their budget in used lube oil re-refining, effective financial management techniques are vital. Employing a strong budgeting and forecasting process helps anticipate expenses, enabling more precise operational planning. Continuous evaluation of operational costs against performance metrics can also identify areas where savings can be achieved.

Moreover, implementing efficiency improvement strategies can help reduce waste and increase value in the re-refining process. Lean methodology, for instance, offers a framework to evaluate operations critically, allowing companies to minimize unnecessary expenditures while enhancing productivity. These methodologies stress the importance of process improvement and continuous learning.

Environmental and economic benefits of re-refining used lube oil

The environmental benefits of used lube oil re-refining are substantial. By recycling waste oil, facilities significantly reduce landfill contributions and pollution emission levels associated with oil waste. The energy savings associated with re-refining are also notable—uses less energy as compared to refining new oil from crude sources. Consequently, companies investing in re-refining processes not only contribute to environmental conservation but also enjoy improved sustainability ratings.

Economically, the re-refining industry promotes job creation within recycling sectors. Skilled positions in science and engineering, maintenance, and operations become available as businesses expand their re-refining capacities. Additionally, companies can achieve long-term savings through sustainable practices and reduced operational costs.

Interactive tools and resources for users

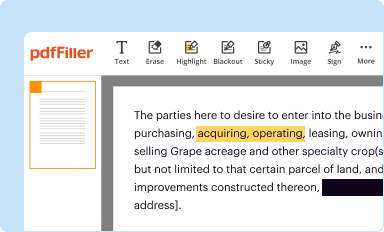

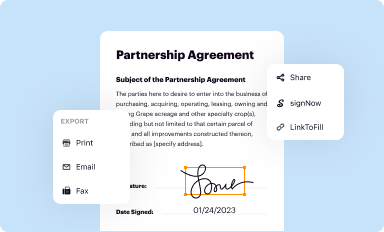

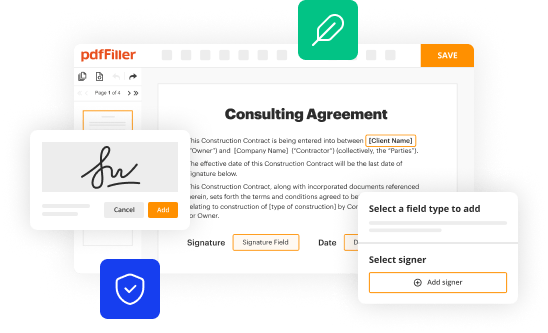

Navigating the paperwork associated with used lube oil re-refining can seem daunting. However, understanding the necessary forms and compliance documentation is crucial for smooth operations. pdfFiller provides an array of resources, including customizable forms for permitting and compliance, which streamline your documentation process.

Additionally, interactive calculators and estimators are available to help businesses evaluate their operational costs, potential savings, and the broader environmental impact of their practices. Utilizing such tools can empower users to make data-driven decisions and enhance overall operational efficiency.

Engaging with the re-refining community

To succeed in the used lube oil re-refining sector, forming connections with industry experts can be incredibly beneficial. Engaging with trade associations and professional networks enables individuals to share knowledge, insights, and best practices in the field. Collaborating with peers can also facilitate access to resources that help navigate complex compliance issues.

Sharing success stories and case studies further strengthens the community’s capacity to innovate in re-refining initiatives. Such collaborative learning exemplifies the impact of effective re-refining practices on both an environmental and economic scale, demonstrating the potential benefits that can be derived from a concerted effort to recycle lube oil.

Conclusion: Empowering your re-refining journey

Embarking on a used lube oil re-refining journey is a significant step toward environmental stewardship and operational efficiency. To effectively utilize resources such as pdfFiller for document management, individuals and teams can streamline their workflows, ensuring timely submissions and compliance with regulatory standards. It is essential to stay engaged in ongoing education, as innovations in the re-refining sector continue to evolve.

Moreover, emphasizing sustainable practices not only bolsters community trust but also enhances organizational reputation. As stakeholders increasingly lean towards companies showcasing their commitment to recycling and environmental responsibility, participating actively in used lube oil re-refining advocacy can yield long-lasting benefits both for businesses and the planet.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send used lube oil re-refining to be eSigned by others?

How do I edit used lube oil re-refining online?

Can I create an electronic signature for signing my used lube oil re-refining in Gmail?

What is used lube oil re-refining?

Who is required to file used lube oil re-refining?

How to fill out used lube oil re-refining?

What is the purpose of used lube oil re-refining?

What information must be reported on used lube oil re-refining?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.