Get the free Basic Mdo–3/4” Concrete Form

Get, Create, Make and Sign basic mdo34 concrete form

Editing basic mdo34 concrete form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out basic mdo34 concrete form

How to fill out basic mdo34 concrete form

Who needs basic mdo34 concrete form?

Basic MDO34 Concrete Form: A Comprehensive Guide

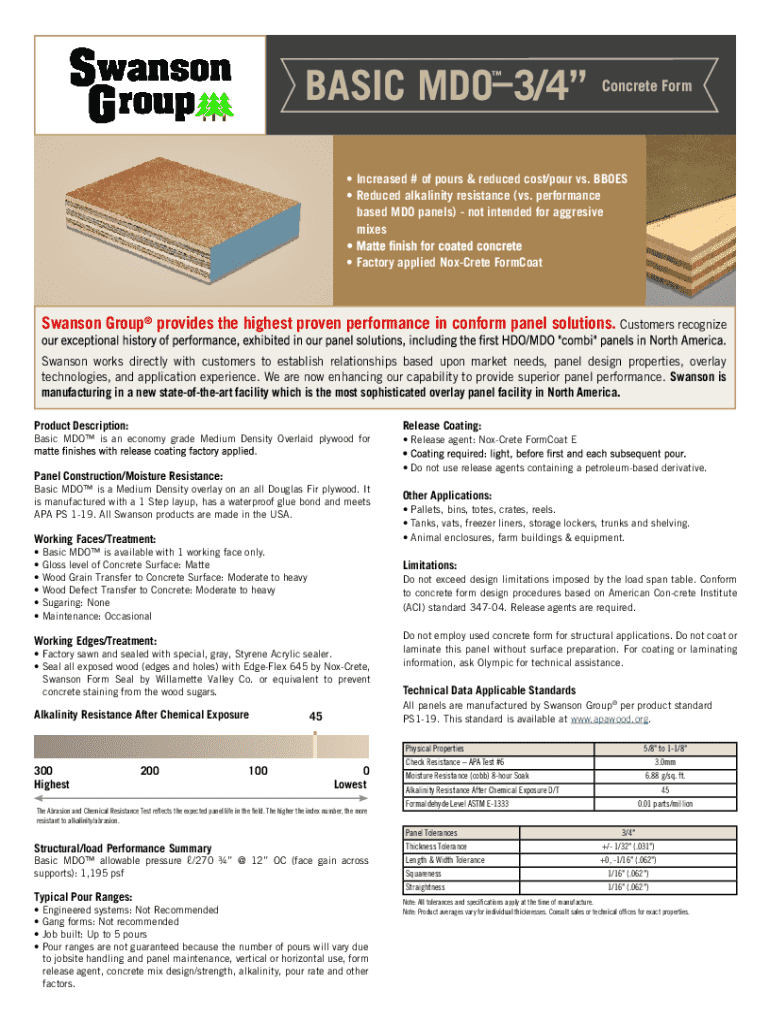

Understanding the MDO34 concrete form

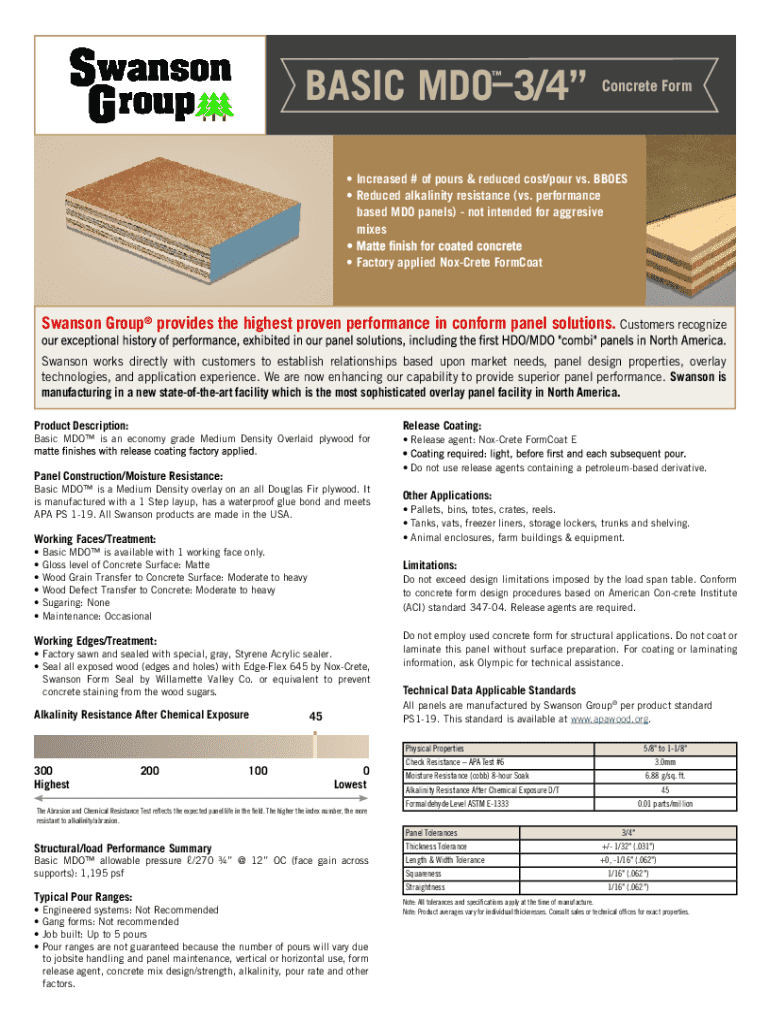

MDO34 concrete forms are essential tools used in the construction industry for creating precise and sturdy concrete structures. These forms are designed to hold wet concrete in place until it sets, ensuring a smooth finish and accurate dimensions. Understanding the purpose and functionality of MDO34 forms is crucial for achieving professional results in concrete projects.

Choosing the right concrete form can significantly affect the efficiency and quality of a construction project. MDO34 forms are particularly favored for their adaptability and cost-effectiveness, making them an important resource in various types of construction.

Material composition and characteristics

MDO34 forms are made from Medium Density Overlay (MDO) plywood, which offers superior durability and moisture resistance compared to traditional plywood forms. The MDO surface provides a smooth finish that minimizes surface defects in the cured concrete, which is vital for aesthetic and structural purposes.

Using MDO34 forms brings several benefits, such as reduced chance of warping, a longer lifespan, and reusability for multiple projects. Their lightweight nature makes them easier to handle, which can translate into time savings during assembly and dismantling.

Tools and equipment needed

Before starting your MDO34 concrete forming project, ensuring you have the right tools and equipment is critical. Here's a list of essential tools you will need:

In addition to the tools for assembling forms, safety should never be overlooked. The following personal protective equipment (PPE) is recommended for construction work with MDO34 forms:

Preparing for concrete pouring

Effective site assessment and preparation are vital steps when working with MDO34 forms. Begin by evaluating the construction site for any potential obstacles, such as uneven terrain or debris. Clear the area thoroughly and ensure the ground is leveled to provide a stable foundation for the forms.

Once the site is prepared, assembling the MDO34 forms becomes the next step. Follow these step-by-step instructions for effective setup:

Mixing and pouring concrete

Achieving optimal strength in concrete requires the right mix ratios. For MDO34 forms, a common recommendation is to use a mix ratio of 1 part cement, 2 parts sand, and 3 parts gravel while maintaining a water-cement ratio of approximately 0.5 for good workability without compromising strength.

When pouring concrete into the MDO34 forms, consider the following best practices to avoid air pockets and achieve even distribution:

Curing and finishing

Curing is a crucial step in concrete work that facilitates proper hydration, leading to optimal strength and durability. Timing for curing usually begins after the concrete has set but should not exceed 24 hours before remediation starts. Common methods include covered curing with wet burlap or using curing compounds.

Finishing techniques can also play a significant role in enhancing the final appearance of the concrete. Consider options such as texturing for slip resistance or smoothing for decorative purposes. Additionally, applying a sealant post-curing can protect the surface from weathering, stains, and moisture penetration.

Maintenance and management of MDO34 forms

Cleaning MDO34 forms after use is imperative for maintaining their integrity and usability. Post-use, rinse off any concrete residue with a high-pressure washer to ensure no build-up, which can lead to corrosion over time. It’s advisable to inspect for damages and replace any problematic panels.

For future projects, ensure proper storage of the forms to prevent warping or damage. Store them in a cool, dry place, ideally stacked on a flat surface, and cover with tarps to protect against moisture.

Troubleshooting common issues

Addressing air pockets in cured concrete is vital for ensuring the structural integrity of the build. Common causes include inadequate pouring techniques or using improper mix ratios. Remedies include reusing vibrators during the pouring process and inspecting the mix thoroughly before application.

Cracking or structural weakness in concrete can result from various factors such as rapid drying or an incorrect water-cement ratio. Regular checks for environmental impacts, combined with effective curing methods, can help mitigate these risks.

Advanced techniques for professional use

Customization of MDO34 forms can be advantageous for unique project specifications. Modify lengths, shapes, or incorporate additional supports like fillets to match specific design requirements, giving enhancement to both functionality and aesthetics.

Innovations in concrete formwork, including the use of 3D modeling tools, help streamline the form creation process. New technologies can help estimate materials more accurately and reduce waste while enhancing precision.

Interactive tools and resources

Utilizing interactive planners and calculators can improve the planning phase of your concrete pouring project. These tools can assist in determining the right amounts of materials needed based on specific form dimensions, promoting accuracy and efficiency in the project.

Community sharing of experiences and tips further enriches the knowledge base around MDO34 form usage, enabling users to learn from each other's successes and challenges. Regularly engaging in forums can aid in discovering innovative solutions to common problems.

Industry applications of MDO34 concrete forms

MDO34 forms have versatile applications ranging from residential projects like foundations and slabs to larger commercial constructions. In residential contexts, they are often used for backyards, driveways, and patios. Conversely, in commercial projects, their robust design supports heavy loads, making them ideal for columns and structural walls.

A notable case study illustrating the effectiveness of MDO34 forms is a local municipal building project that achieved remarkable aesthetic appeal and structural strength through careful planning and execution of formwork. Such examples highlight the reliability of MDO34 forms across different scales and types of constructions.

Frequently asked questions (FAQs)

Several queries arise regarding MDO34 concrete forms. Common questions include how to choose the right form for a specific job and troubleshooting problems during the curing phase. Readers often seek practical insights based on user experiences, such as how to avoid overloading forms during pour-in.

Recommendations from experienced users particularly focus on adapting techniques to varying environmental conditions and customizing mix ratios for specific applications. Understanding their insights can lead to better outcomes in concrete work.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my basic mdo34 concrete form in Gmail?

How do I make edits in basic mdo34 concrete form without leaving Chrome?

How do I complete basic mdo34 concrete form on an iOS device?

What is basic mdo34 concrete form?

Who is required to file basic mdo34 concrete form?

How to fill out basic mdo34 concrete form?

What is the purpose of basic mdo34 concrete form?

What information must be reported on basic mdo34 concrete form?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.