Get the free Burnishing

Get, Create, Make and Sign burnishing

Editing burnishing online

Uncompromising security for your PDF editing and eSignature needs

How to fill out burnishing

How to fill out burnishing

Who needs burnishing?

Comprehensive Guide to Burnishing Forms

Understanding burnishing forms

Burnishing is a finishing process used in manufacturing where a hard tool is used to smooth and polish the surface of a workpiece. The process involves the application of pressure, which compresses the surface material, leading to a reduction in surface roughness and an increase in glossiness. It’s crucial in various industries as it enhances the final appearance and functionality of parts.

This sophisticated technique not only improves aesthetics but also significantly affects component performance and durability. Burnishing forms facilitate the organized execution of this process, ensuring all parameters are captured, leading to consistent results across batches.

Applications of burnishing forms

Burnishing forms find their applications across diverse industries, each leveraging the technique to enhance the efficiency and quality of their components. The aerospace and automotive industries, for instance, utilize burnishing for critical components that require precision and reliability under extreme conditions.

Similarly, precision engineering backs the utilization of burnishing in creating intricate parts where dimensional accuracy and a smooth surface finish are paramount. The benefits of using burnishing forms are clear:

Types of burnishing forms

Various methods of burnishing exist, each suited to different applications. Roller burnishing is one of the most common techniques, where a series of rollers apply pressure to the surface, resulting in enhanced finish without significant material removal. This method is highly robust, often utilized for external and internal surfaces of cylinders.

Another technique, skive burnishing, uses a skiving tool to achieve smooth finishes. It differs from roller burnishing in its approach, often providing more precise control over depth and comfort. Custom burnishing tools offer tailored solutions for specific applications, such as deep rolling for intricate features and finish machining to hone to perfection.

Key features of effective burnishing forms

Selecting the right materials is crucial when it comes to burnishing forms. Different materials respond differently to burnishing, and recognizing which ones are compatible plays a vital role in achieving optimal results. Metals such as steel and aluminum are frequently burnished due to their malleability and finish quality.

Surface finish requirements must also be adhered to strictly. Each industry has its standards, dictating how smooth a finish needs to be. Quality checks, including measuring surface roughness with specific gauges, are essential to ensure compliance with these standards, making it easier to pinpoint weaknesses or areas for improvement.

Step-by-step guide to using burnishing forms

Preparing for the burnishing process begins with selecting the proper equipment based on the workpiece material and desired finish quality. Understanding properties like hardness and elasticity will guide tool choice. Establishing a well-organized workspace free from contaminants is also crucial to avoid imperfections.

Filling out the burnishing form appropriately cannot be overlooked. Basic information – such as material type, dimensions, and required finish standards – is critical. More detailed fields may include specific tolerances and any previous treatments or processes the workpiece has undergone.

The burnishing process itself can differ based on the method used. For roller burnishing, the step-by-step instructions include selecting the right tools, setting them up properly, and following specific operating procedures to maintain consistency. Techniques may vary slightly when adapting to different component types and integrated requirements.

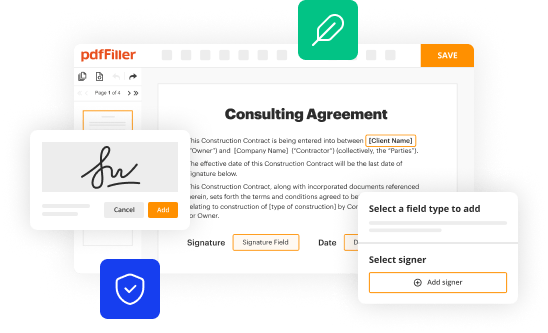

Post-burnishing tasks involve thorough quality checks to ensure standards are met and that no defects occurred during the process. Documenting the results is also key; utilizing forms succinctly recorded on platforms like pdfFiller can streamline the documentation process and ensure all necessary information is captured for future reference.

Advanced techniques in burnishing

Combining burnishing with other finishing methods – a practice known as hybrid techniques – can result in outstanding surface finishes. For example, applying heat treatments prior to burnishing can enhance the material properties and facilitate an even smoother finish. The evolving landscape of burnishing also sees innovations through technological advancements that enable new equipment designs, making the process faster and more efficient.

Moreover, sustainable practices are increasingly taking shape in the industry. Using eco-friendly lubricants and optimizing the burnishing process not only leads to better environmental outcomes but also enhances the final surface quality. Companies integrating these sustainable practices often report greater efficiency in production cycles.

FAQs about burnishing forms

There’s often a lot of confusion surrounding burnishing forms. One common question is, “What materials can be burnished?” In general, metals like steel, brass, and aluminum are the most commonly burnished due to their properties, though some plastics can also undergo a form of burnishing.

Another frequently asked question is how to choose between roller and skive burnishing. Roller burnishing is typically preferred for more extensive, smoother finishes, while skive burnishing is ideal for precision work where detail is critical. For tools, the effectiveness can vary, but robust options like carbide-tipped tools often yield the best results across various burnishing applications.

Support and troubleshooting

Identifying common issues related to the burnishing process is essential for continuous improvement. Issues can range from uneven surfaces to tool wear, and troubleshooting involves analyzing each stage of the process. Having access to resources for assistance, such as interactive tools on pdfFiller for form management or instructional videos for complex burnishing tasks, ensures that users can address problems swiftly, thereby maintaining productivity.

Customer experiences and case studies

Real-world applications of burnishing forms often illustrate their effectiveness and essential role in various sectors. For instance, numerous aerospace manufacturers have reported reduced downtime and improved product quality after streamlining their burnishing processes through precise documentation and form management. Users of the pdfFiller platform have shared positive experiences in managing critical documentation related to burnishing applications, proving that efficient documentation methods can directly impact results.

Conclusion of burnishing knowledge

In summary, understanding burnishing forms is fundamental in achieving high-quality finishes essential for many industries. These forms not only streamline the process but also ensure that manufacturers adhere to industry standards and protocols for quality assurance. As companies increasingly turn to platforms like pdfFiller to manage their documentation, the integration of technology with traditional techniques will continue to enhance production quality and sustainability in the long run.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit burnishing from Google Drive?

How can I edit burnishing on a smartphone?

How do I edit burnishing on an Android device?

What is burnishing?

Who is required to file burnishing?

How to fill out burnishing?

What is the purpose of burnishing?

What information must be reported on burnishing?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.