Get the free Compact Piezo

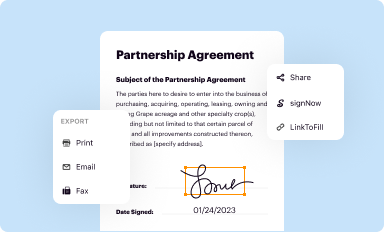

Get, Create, Make and Sign compact piezo

Editing compact piezo online

Uncompromising security for your PDF editing and eSignature needs

How to fill out compact piezo

How to fill out compact piezo

Who needs compact piezo?

A comprehensive guide to compact piezo forms: Harnessing technology for precision and performance

Overview of compact piezo technology

Compact piezo technology refers to the utilization of piezoelectric materials in a minimized form, allowing for efficient space and weight management without sacrificing performance. These devices convert mechanical energy into electrical energy and vice versa, making them crucial in various applications. Compact piezo forms are vital in sectors like aerospace, automotive, medical devices, and consumer electronics, where space constraints and performance demands are high.

Compared to conventional piezo technologies, compact piezo forms offer a more streamlined design, reducing the material required for construction while enhancing functionality. This enables engineers and designers to create powerful devices that fit seamlessly into smaller designs, pushing the boundaries of what is possible in each industry.

Key advantages of using compact piezo forms

Several advantages make compact piezo forms an appealing choice for engineers and manufacturers alike. Firstly, their size and weight efficiency allow for significant miniaturization, making them a distinct solution for applications where space is at a premium. For example, in portable medical devices, compact piezo elements ensure functionality without adding unnecessary bulk.

Enhanced performance metrics include improved responsiveness and precision, making these devices suitable for high-performance applications. Furthermore, their cost-effectiveness benefits long-term projects by minimizing waste during production and lowering energy consumption during operation.

Understanding the functionality of compact piezo devices

To appreciate the functionality of compact piezo forms, it's crucial to understand the critical components involved. The primary elements are the piezoelectric materials – often ceramics or polymers – which generate an electrical charge when mechanically stressed. These materials are integrated into circuits designed to manage and amplify the generated signals effectively.

The mechanisms of action in compact solutions often involve a direct interplay between electrical signals and mechanical movement. When an electrical signal is applied to the piezoelectric material, it expands or contracts, causing a mechanical action that can be harnessed for various applications, from simple switch mechanisms to sophisticated actuators in robotic systems.

Process of integrating compact piezo forms in projects

Integrating compact piezo forms into a project involves a clear set of steps to ensure efficiency and effectiveness. It starts with pre-installation considerations, such as understanding the specific requirements of your application and selecting the appropriate piezo device.

Common challenges include ensuring proper alignment and connection of the piezoelectric components. Troubleshooting involves checking electrical connections and ensuring the circuit is correctly integrated, which can be accomplished by carefully reviewing project documentation and seeking advice from experts if needed.

Using interactive tools for customization

To maximize the potential of compact piezo forms, utilizing interactive tools for customization is essential. Online platforms allow for easy design adjustments based on specific project requirements. These solutions can help engineers and designers visualize modifications in real time and ensure compatibility with their existing systems.

The incorporation of user-friendly interfaces simplifies the design process, making it more accessible even for teams with varying levels of technical expertise.

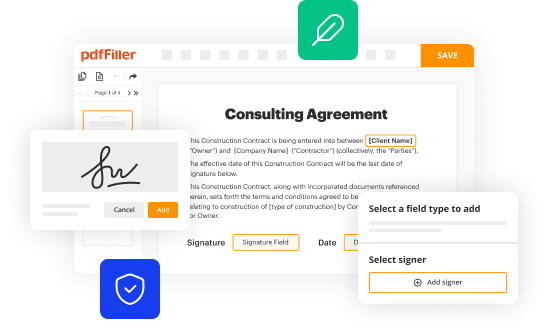

Editing and managing compact piezo form templates

Managing templates for compact piezo forms is a streamlined process within the pdfFiller platform. Users can easily download templates tailored to their needs and modify them as necessary. Collaboration features enable multiple team members to work simultaneously on revisions, ensuring a cohesive final product.

This flexibility not only saves time but also enhances communication across teams, making project execution smoother and more effective.

Technical specifications and manuals for compact piezo forms

For users engaged in the implementation of compact piezo forms, understanding the technical specifications of each component is vital. These details include the dimensions, weight, electrical characteristics, and the type of piezoelectric material used. Access to comprehensive manuals further aids in the installation and maintenance phases.

Understanding these specifications ensures that users can make informed decisions and maintain high performance throughout the device's lifecycle.

Real-world applications and case studies of compact piezo forms

The practical utility of compact piezo forms can be best understood through real-world applications and case studies. In the automotive industry, for instance, compact piezo actuators are used in advanced driver assistance systems (ADAS) to precisely control sensor positions. This results in enhanced safety features and improved vehicle performance.

Through these tangible examples, potential users can gauge the effectiveness of compact piezo forms in enhancing operational capabilities across different fields.

Frequently asked questions about compact piezo technology

As interest in compact piezo technology grows, so do the questions from potential users. Common queries often revolve around the reliability and lifetime of compact piezo forms in various applications, as well as concerns about adaptability in different environments.

Providing clear answers ensures that users feel confident and informed as they navigate their projects involving compact piezo technologies.

Future trends in compact piezo technology

As technology continues to evolve, so does the landscape of compact piezo forms. Future innovations may lead to the development of new materials that improve efficiency and reduce cost further. These changes could significantly influence manufacturing processes, possibly leading to widespread adoption across various sectors.

Being aware of these trends helps users stay ahead of the curve and prepares them for the next generation of compact piezo technology.

Navigating your options for compact piezo solutions

When considering the integration of compact piezo forms into projects, it’s essential to evaluate the various options available. Different manufacturers offer unique designs with specialized functions tailored to specific needs, from medical applications to automotive systems.

Such evaluations ensure that the selected device not only meets the technical requirements but also aligns with the project’s overall goals.

Feedback and customer interaction

Collecting user feedback is critical for continuous improvement in compact piezo solutions. Engaging with engineers and previous users can provide insights into the design's efficacy and highlight areas for enhancement. This feedback loop is invaluable for manufacturers looking to innovate.

In this way, manufacturers can foster a collaborative environment where user input drives technology evolution.

Contact support for setup and technical assistance

Having access to a variety of support channels is essential for users integrating compact piezo forms into their projects. Being prepared with relevant information when seeking assistance can streamline the troubleshooting process. Support teams can resolve issues more efficiently when they have details about the specific model and context of use.

By leveraging available support systems, users can maximize their effectiveness in deploying compact piezo technology.

Quick links and additional tools for further exploration

To deepen understanding and functionality surrounding compact piezo forms, utilizing quick links to related products and resources is beneficial. Integration with other technologies can expand the applicability of solutions while keeping pace with key industry trends.

These resources empower users to effectively develop and implement compact piezo technologies in their projects, ensuring they remain at the forefront of innovation.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for the compact piezo in Chrome?

Can I create an eSignature for the compact piezo in Gmail?

How can I edit compact piezo on a smartphone?

What is compact piezo?

Who is required to file compact piezo?

How to fill out compact piezo?

What is the purpose of compact piezo?

What information must be reported on compact piezo?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.