Get the free pcb inspection checklist

Get, Create, Make and Sign pcb inspection checklist form

How to edit pcb inspection checklist form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out pcb inspection checklist form

How to fill out pcb inspection checklist revised

Who needs pcb inspection checklist revised?

PCB Inspection Checklist Revised Form: Ensuring Quality in Electronics Manufacturing

Overview of PCB inspection

PCB inspection is a critical process in the electronics manufacturing industry. It involves examining printed circuit boards (PCBs) to ensure they meet specified quality standards and performance requirements. The significance of PCB inspection cannot be overstated, as defects in PCBs can lead to costly failures in electronic devices, affecting quality control and customer satisfaction.

The primary objectives of the PCB inspection process are to identify defects early, validate component placement, ensure function and reliability, and maintain compliance with industry standards. With the increased complexity of electronic designs, a well-structured inspection checklist is essential for thorough assessments.

Components of a PCB inspection checklist

A comprehensive PCB inspection checklist serves as a guide for inspectors, ensuring all critical aspects are covered. Here are the main components:

Step-by-step guide to using the PCB inspection checklist revised form

Using the revised PCB inspection checklist is essential for consistent and effective inspections. The following steps outline the procedure:

Enhancing PCB inspection effectiveness

To enhance the effectiveness of PCB inspections, adhering to best practices in checklist development is vital. Customizing checklists to suit different PCB types ensures comprehensive coverage of specific needs. Regular updates to the checklist are equally important as technology and standards evolve, and periodic training sessions for inspectors can foster knowledge retention.

Leveraging technology can further streamline inspection processes. Utilizing tools like PDFfiller for document management not only simplifies record-keeping but also allows for easy updates and sharing among team members. Interactive formats can facilitate real-time feedback, enabling more efficient collaboration.

Integration of PCB inspection checklist in team workflows

Integrating the PCB inspection checklist into team workflows involves establishing an online inspection portal. This provides a centralized location for accessing the checklist and related documents, enhancing transparency and accessibility for all team members.

Collaboration features available in PDFfiller allow teams to communicate findings effectively and document necessary changes promptly. Feedback mechanisms should also be incorporated into the workflow, enabling continual improvement based on inspector observations and team discussions.

Real-world applications and case studies

Several real-world applications demonstrate the efficacy of efficient PCB inspections. Companies that utilize structured checklists have reported significant improvements in defect detection rates and reduced rework.

Challenges in the inspection process often involve time constraints or lack of training. However, industry leaders have overcome these obstacles by standardizing their checklists and investing in training programs that emphasize the importance of detailed inspections. This approach not only improves PCB quality but also enhances overall production efficiency.

FAQ section

When it comes to PCB inspection, many common questions arise. Here are some frequently asked questions and their clarifications:

Additional tips for effective PCB management

Continuous improvement is essential for successful PCB management, especially concerning inspections. Techniques such as root cause analysis of defects, incorporating feedback from inspectors, and refining inspection processes can lead to significant advancements in product quality.

Moreover, establishing a strong link between checklists and overall quality assurance models will ensure that inspections are not merely procedural but part of a wider commitment to excellence. Future trends may include increased automation in inspection technologies, further integrating AI and machine learning to refine the detection of anomalies in PCB quality.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my pcb inspection checklist form in Gmail?

How do I make changes in pcb inspection checklist form?

How do I edit pcb inspection checklist form on an iOS device?

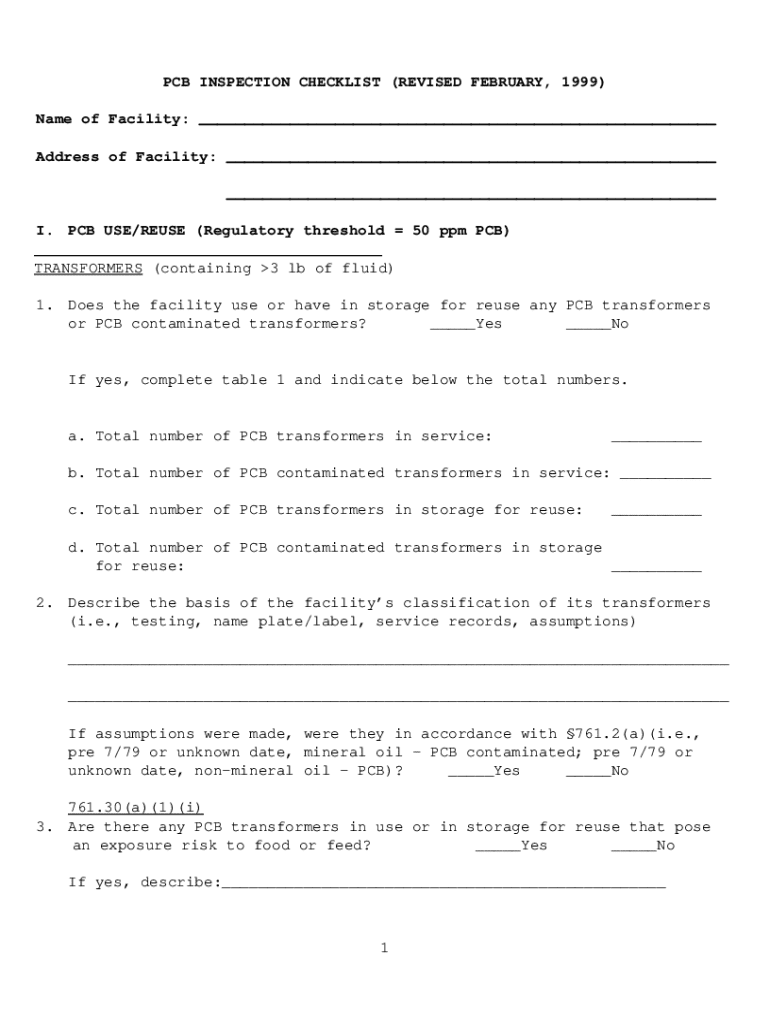

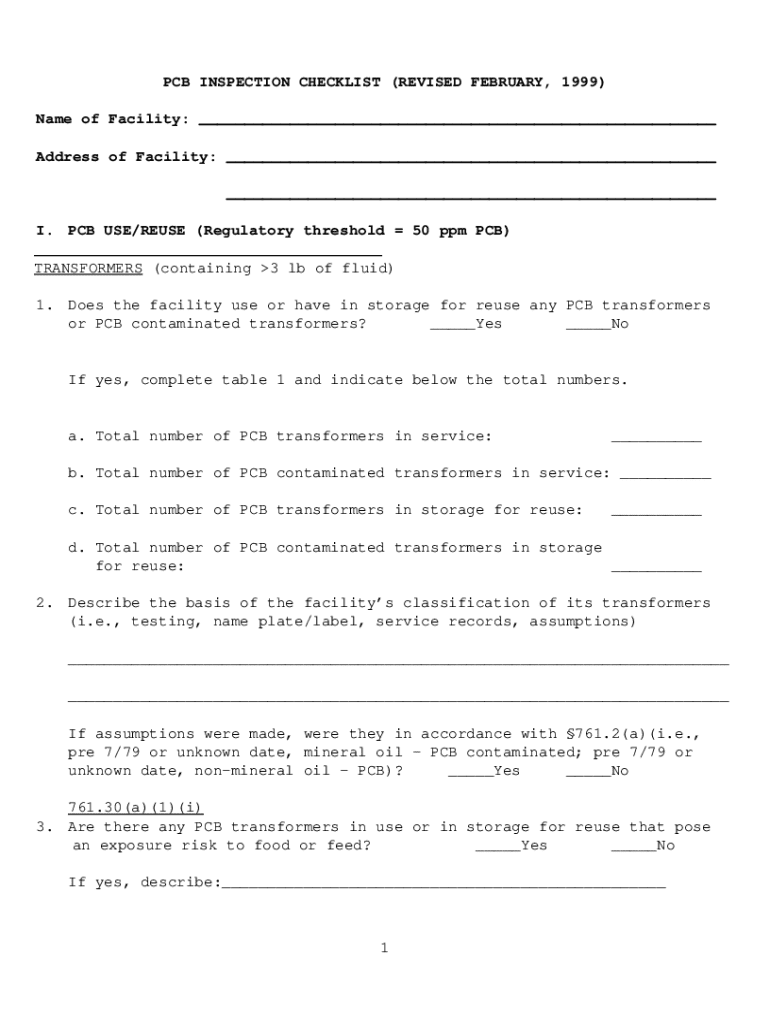

What is pcb inspection checklist revised?

Who is required to file pcb inspection checklist revised?

How to fill out pcb inspection checklist revised?

What is the purpose of pcb inspection checklist revised?

What information must be reported on pcb inspection checklist revised?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.