Technical Quality For Manufactur Contract Template free printable template

Show details

This document outlines the terms and conditions for engagement between a Client and a Manufacturer regarding the production of goods meeting specific technical quality standards.

We are not affiliated with any brand or entity on this form

Why pdfFiller is the best tool for managing contracts

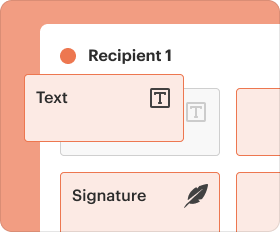

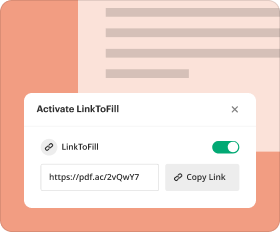

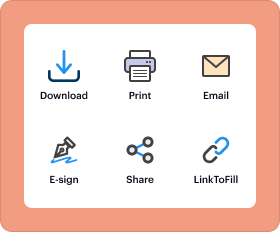

End-to-end document management

From editing and signing to collaborating and tracking, pdfFiller has all the PDF tools you need for your contract workflow.

Mobile ready

pdfFiller is cloud-based, letting you edit, sign, and share contracts from your computer, smartphone, or tablet.

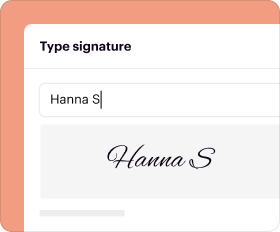

Legally binding & secure

pdfFiller lets you securely manage contracts with eSignatures that comply with global laws like ESIGN and GDPR. It's also HIPAA and SOC 2 compliant.

What is Technical Quality For Manufactur Contract Template

The Technical Quality For Manufacturing Contract Template is a document designed to outline the quality standards and specifications required for manufacturing processes and products.

pdfFiller scores top ratings on review platforms

I’m new to PDFfiller. Like the create document feature, although have to search and search for specific forms....Not easy to access. But do find PDFfiller beneficial, useful. Will continue to subscribe to this platform. Great for personal use as well as business use.

Very easy to use, and great software product.

Tutorial would be helpful to know all the tricks

Easy to use, made me filling a document for 2 days into a 2 hour thing.

It has helped me succeed in my business. Very user friendly.

Very technical but probably great for executive assistants and paralegals, not so hot for professional musicians without administrative training.

Who needs Technical Quality For Manufactur Contract Template?

Explore how professionals across industries use pdfFiller.

Detailed Guide on Technical Quality for Manufacture Contract

How important is technical quality in manufacturing contracts?

Technical quality is crucial for ensuring that manufactured products meet both industry standards and client expectations. Poor technical quality can lead to defects, increased costs, and damaged reputations. Understanding the key elements that define technical quality standards helps in establishing a solid contractual foundation.

-

Overview of technical quality and its impact on manufacturing outcomes: High technical quality ensures that products are not only functional but also compliant with safety and durability benchmarks.

-

Key elements that define technical quality standards: These include specifications, testing protocols, and monitoring processes that guide production.

-

The role of compliance in ensuring product integrity: Adhering to regulatory standards mitigates risks associated with non-compliance, such as legal action or product recalls.

What are the key components of a manufacturing contract?

Understanding the key components of a manufacturing contract is essential for ensuring clarity and mutual understanding between the parties involved. A strong contract can minimize disputes and establish clear channels for communication.

-

Identification of the parties involved: Clearly stating who the client and manufacturer are sets the contractual groundwork.

-

Establishing the scope of work and specifications: This helps in avoiding misunderstandings about what is to be produced and the quality expected.

-

Defining roles and responsibilities regarding quality assurance: Establishing accountability for quality management in the manufacturing process is key to meeting technical standards.

How can you craft effective technical quality standards?

Crafting effective technical quality standards is an essential part of the manufacturing contract, guiding both the client and the manufacturer throughout the production process. It involves establishing measurable benchmarks that are easy to understand and implement.

-

Elements that make up technical quality standards: Specifications, measurement techniques, and acceptable quality levels are all part of these standards.

-

Benchmarks and metrics for evaluating technical quality: Implementing quantifiable metrics allows for easier assessment of product quality.

-

Documentation and specifications required for compliance: Properly documenting these standards is crucial for compliance and quality assurance.

What are the key definitions relevant to technical quality in manufacturing?

Defining key terms related to technical quality helps in setting expectations and reduces the risk of disputes later in the contract life cycle. Clear definitions also facilitate better communication between the contracting parties.

-

Clarification of key terms: Technical Quality refers to the standard of the products produced based on predetermined metrics.

-

Examples of how these terms apply in real-world scenarios: For instance, a high 'Manufacturer' must ensure that all processes meet quality controls consistently.

-

Importance of clear definitions in avoiding contract disputes: Misunderstandings over terms can lead to disputes, emphasizing the need for precise language.

What steps should you take in creating a manufacturing contract?

Creating a manufacturing contract involves several key steps that must be carefully followed to ensure both legal validity and practical efficacy. Each step must be documented properly to reinforce the technical quality expectations laid out previously.

-

Pre-contract considerations: Assessing manufacturer capability and standards ensures that the selected partner can meet the specified requirements.

-

Drafting the contract: Key clauses related to technical quality must be included to protect both parties' interests.

-

Review and negotiation process: Ensuring mutual agreement on terms of the contract fosters a collaborative environment.

How can you ensure quality assurance throughout the manufacturing process?

Quality assurance is an ongoing process that must be integrated at every stage of manufacturing. Regular checks and balances will help maintain the required standards and ensure overall product integrity.

-

Implementing quality control measures before production begins to ensure all processes are in line with established standards.

-

Periodic assessments and compliance checks: Regular evaluations help in identifying potential issues before they become significant.

-

Process for addressing non-compliance issues: A clear procedure for rectification is essential for maintaining standards.

How do you manage changes in technical quality standards?

Managing changes in technical quality standards involves formal procedures to ensure all parties are aligned and compliant. Effective communication is key during this transition to avoid misunderstandings.

-

Procedures for amending contracts: Clear guidelines on how to modify existing contracts in response to updated standards.

-

Impact assessment of changes on the manufacturing process: Evaluating how changes affect current operations ensures continued compliance.

-

Communication strategies: Keeping both parties informed mitigates confusion during transitions.

What are best practices for collaborating with manufacturers?

Effective collaboration with manufacturers can lead to enhanced quality and smoother operational flows. Utilizing best practices in communication and feedback mechanisms contributes to achieving technical quality.

-

Building and maintaining effective communication channels: This establishes trust and ensures stakeholders are aligned.

-

Establishing ongoing feedback mechanisms: Regular assessments and feedback aid in consistent quality improvement.

-

Strategies for fostering a collaborative environment: Focusing on shared goals leads to better outcomes in technical quality.

How to fill out the Technical Quality For Manufactur Contract Template

-

1.Access the Technical Quality For Manufacturing Contract Template on pdfFiller.

-

2.Begin by entering the names and addresses of the involved parties in the designated fields.

-

3.Specify the scope of work and detailed descriptions of the products or services being manufactured.

-

4.Outline the quality standards and specifications required, referencing any relevant industry standards.

-

5.Include testing and inspection criteria, detailing how quality will be monitored and assessed.

-

6.Set forth timelines for delivery, acceptance, and any penalties for non-compliance with quality standards.

-

7.Detail the terms for modifications or amendments to the contract, if necessary.

-

8.Review the entire document for accuracy, ensuring all sections are filled in.

-

9.Save and download the completed contract for distribution to all parties involved.

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.