Get the free Boiler and Pressure Plant Insurance Proposal Form

Get, Create, Make and Sign boiler and pressure plant

How to edit boiler and pressure plant online

Uncompromising security for your PDF editing and eSignature needs

How to fill out boiler and pressure plant

How to fill out boiler and pressure plant

Who needs boiler and pressure plant?

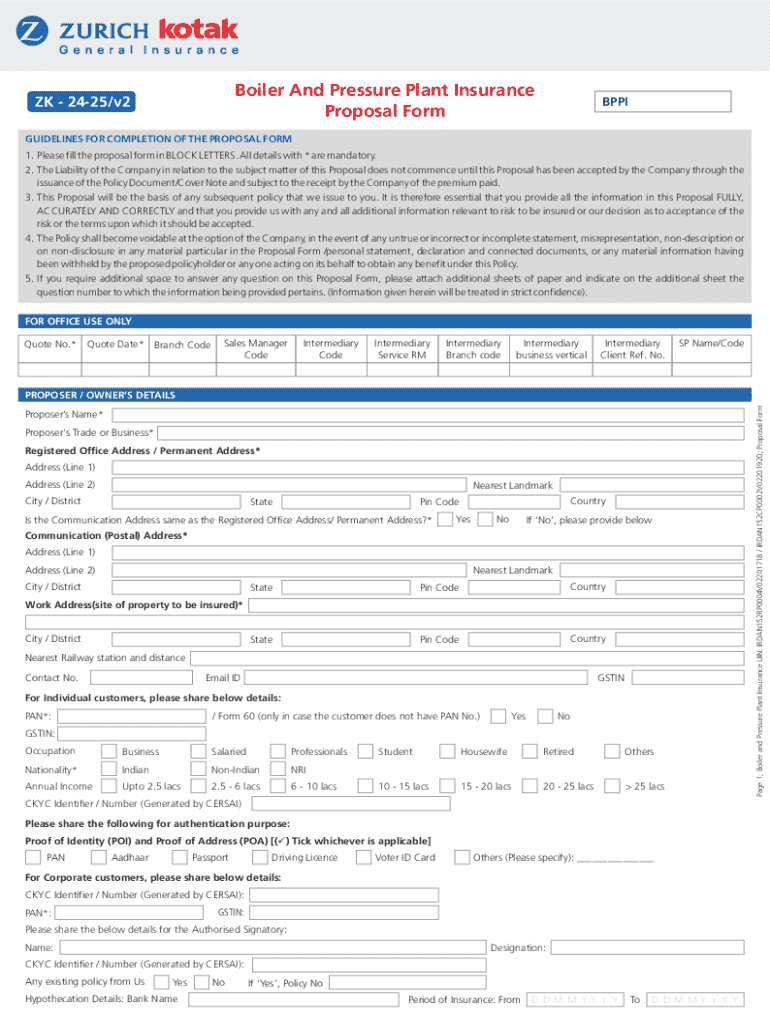

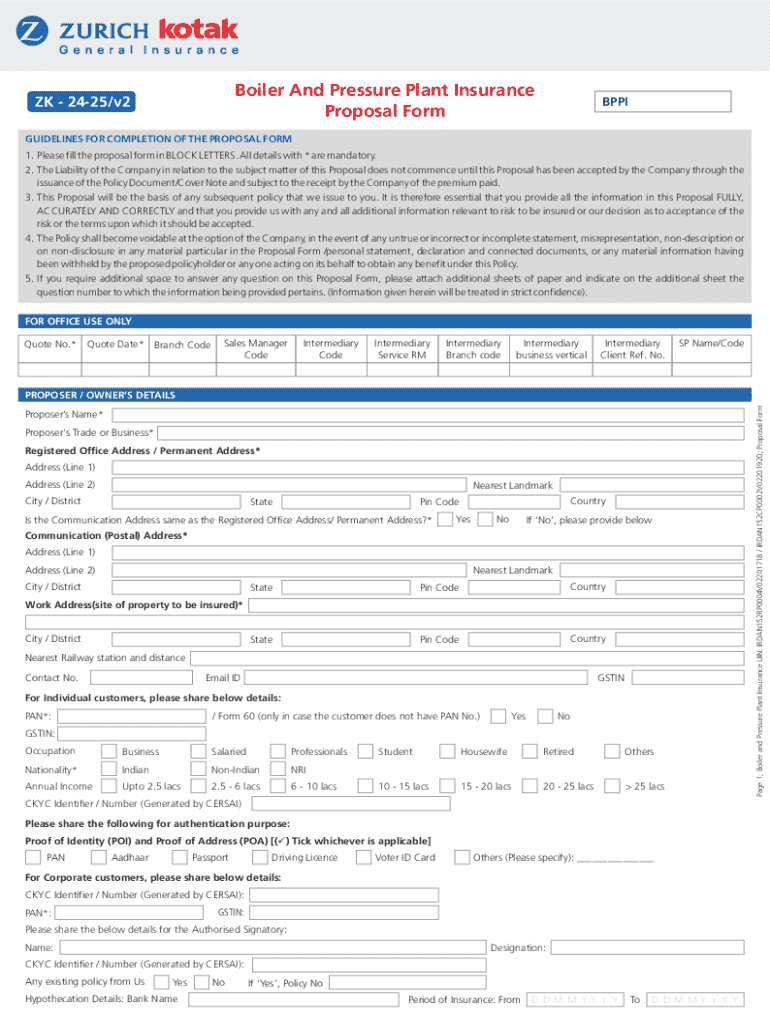

A comprehensive guide to the boiler and pressure plant form

Understanding the boiler and pressure plant form

The boiler and pressure plant form serves as a crucial document in the operation and maintenance of pressure equipment, ensuring that all facilities adhere to necessary safety and compliance standards. This form captures vital information about boilers and pressure vessels, helping facility operators manage and inspect their equipment effectively.

The significance of the boiler and pressure plant form lies in its role in regulatory compliance. Industries operating pressure equipment must follow strict guidelines to prevent accidents and ensure safe operation. By maintaining accurate records through this form, companies can demonstrate compliance with safety regulations, providing peace of mind to both employees and stakeholders.

Who needs the boiler and pressure plant form?

The boiler and pressure plant form is essential for various stakeholders within organizations. Facility managers must fill out this form regularly to ensure that their boiler systems are operational and compliant. Compliance officers depend on it to assess regulatory adherence, while engineers and technicians use the information to conduct inspections, maintenance, and upgrades.

The form acts as a guide for operations in different scenarios: The installation of new pressure equipment, the inspection process for existing machinery, and during routine audits. Understanding who needs this form helps streamline responsibilities across departments and ensures proper handling according to legal requirements.

Preparation before filling out the form

Before diving into the boiler and pressure plant form, it's critical to prepare adequately. This includes gathering all necessary documentation that supports the claims made on the form. Popular documents include equipment operation manuals, maintenance records detailing past inspections and repairs, and comprehensive inspection reports that highlight compliance statuses.

Another preparatory step involves identifying stakeholders involved in the filling and reviewing process. Engaging with internal team members such as safety officers and engineers is essential, as well as ensuring communication with any relevant external regulatory bodies. The more coordinated the effort, the smoother the process will be.

Step-by-step guide to filling out the boiler and pressure plant form

Filling out the boiler and pressure plant form can seem daunting. However, breaking it down into manageable sections simplifies the process significantly. Here’s a detailed step-by-step guide:

Section 1: General information

Begin by entering the facility's details. This typically includes the name of the facility, its address, and contact information. Following this, include equipment identification such as the model, serial number, and location within the premises.

Section 2: Specifications of boiler and pressure equipment

Input technical specifications such as pressure ratings, capacity, and any unique operational parameters. Accurately reporting these measurements is crucial, as errors can lead to compliance issues or even safety hazards.

Section 3: Compliance and safety standards

In this section, outline all safety protocols associated with the operation of the equipment. This includes attaching required documentation that supports safety practices. Checklists and relevant certifications may be useful in this section.

Section 4: Signing and verification

Finally, ensure that all necessary parties verify the document by signing it. Understand the legal implications of this step and the importance of obtaining signatures from all relevant stakeholders. This legitimizes the form and confirms that all information provided is accurate.

Editing and managing your form efficiently using pdfFiller

Using pdfFiller enhances the efficiency of filling out the boiler and pressure plant form. The platform allows users to edit the form dynamically, which is especially useful if errors are spotted after initial entry. You can make corrections and updates swiftly, ensuring that the information remains current.

Collaboration is also simplified through pdfFiller. The platform includes features for adding notes and comments, which facilitate discussions among team members. These tools are instrumental in ensuring that everyone is on the same page. Furthermore, pdfFiller offers cloud storage options, enabling you to organize forms by project or type for easy access and management.

eSigning the boiler and pressure plant form

Understanding the legal validity of eSignatures is crucial in today’s digital documentation environment. Using pdfFiller, you can easily initiate the eSigning process for the boiler and pressure plant form. This modern approach simplifies the process of gathering necessary approvals, making it possible for all parties to sign from virtually anywhere.

To ensure a secure signing experience, it's advisable to use strong verification methods during the eSigning process. Sharing documents securely and ensuring all parties understand the signing process minimizes lost time and potential delays.

Troubleshooting common issues during form completion

While filling out the boiler and pressure plant form, several common mistakes can arise. For instance, misreporting equipment specifications is an error that could lead to non-compliance and safety risks. Ensuring every entry is double-checked against reliable sources can prevent this.

Another critical mistake is omitting required signatures from involved parties. It's essential to build a robust review process that allows feedback before final submission. Additionally, familiarize yourself with common technical issues that users face when using pdfFiller, and ensure your team knows how to troubleshoot efficiently.

Collaboration tips for teams working on the boiler and pressure plant form

Effective collaboration is key to successfully filling out the boiler and pressure plant form. Assigning specific roles and responsibilities within the team ensures that each member knows what they need to contribute. Keeping communication channels open helps keep everyone informed about progress and any issues that arise.

Utilizing pdfFiller's collaborative tools can enhance teamwork. Conducting regular check-ins and using the comment feature to enhance discussions about entries can help prevent misunderstandings and promote efficiency. This approach will lead to a comprehensive and accurately filled form.

Finalizing and submitting the boiler and pressure plant form

Before submitting your boiler and pressure plant form, utilize a checklist to ensure that all necessary elements are included. This should comprise verifying that all required attachments are present and confirming the accuracy of all information filled out.

Once everything is in order, pdfFiller allows for direct submission of the form. You can choose to submit it directly through the platform, or you have the option to send it via email, making the submission process both flexible and straightforward.

Post-submission follow-up and management

After successfully submitting the boiler and pressure plant form, it’s essential to track its status. Keeping an eye on feedback received from regulatory bodies can help manage any follow-up action required. It’s important to stay engaged with the regulatory process to ensure compliance throughout.

Using pdfFiller, you can efficiently store and revisit submitted forms for future reference. This capability not only aids tracking but also provides a great resource when preparing for subsequent inspections or audits.

Dynamic updates and revisions based on regulatory changes

Regulatory standards governing boilers and pressure equipment are subject to change, making it imperative for organizations to remain compliant. To navigate this landscape effectively, it's crucial to continually update the boiler and pressure plant form according to evolving regulations.

The pdfFiller platform simplifies this process, allowing users to make dynamic updates swiftly. By monitoring specific legislative changes and utilizing reliable resources to stay informed, organizations can adapt their forms in real time, preventing compliance issues.

Utilizing interactive tools for enhanced form interaction

pdfFiller offers a suite of interactive features that enhance the experience of filling out the boiler and pressure plant form. Smart fields that auto-fill areas based on previous entries streamline the process, significantly reducing time spent on repetitive data input.

The platform also supports real-time collaboration, allowing multiple users to engage simultaneously. This feature not only speeds up the completion process but also fosters creativity and insight-sharing among team members, ultimately resulting in a more comprehensive and accurate form submission.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my boiler and pressure plant directly from Gmail?

How can I send boiler and pressure plant for eSignature?

Can I edit boiler and pressure plant on an iOS device?

What is boiler and pressure plant?

Who is required to file boiler and pressure plant?

How to fill out boiler and pressure plant?

What is the purpose of boiler and pressure plant?

What information must be reported on boiler and pressure plant?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.