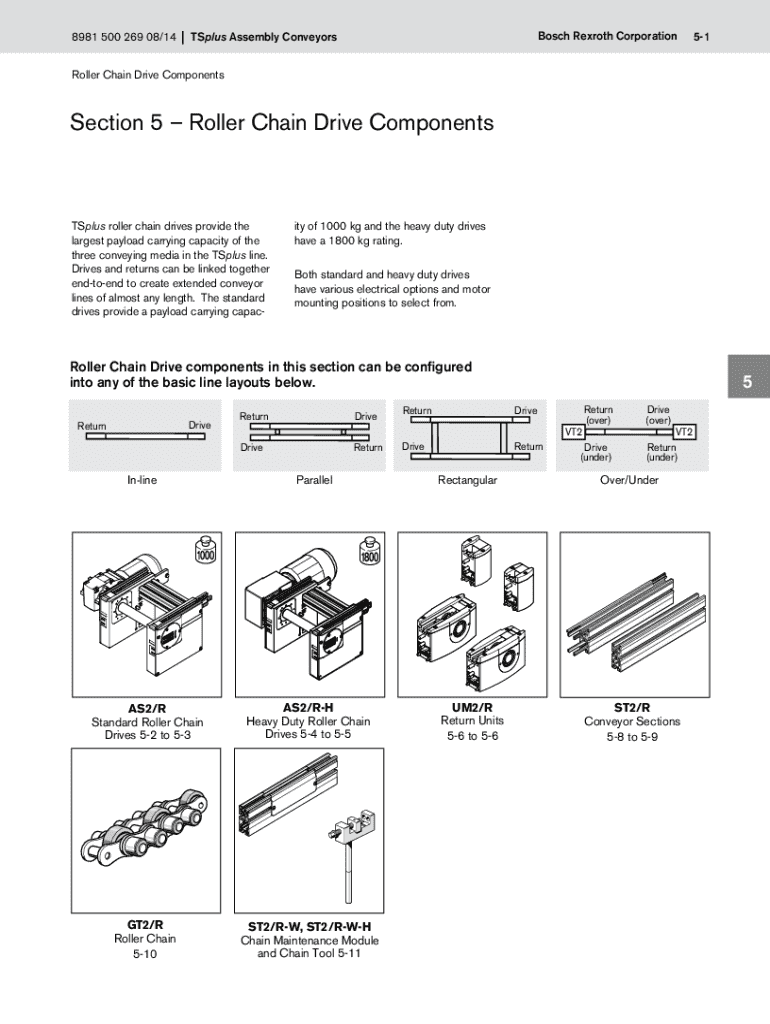

Get the free Roller Chain Drive Components

Get, Create, Make and Sign roller chain drive components

Editing roller chain drive components online

Uncompromising security for your PDF editing and eSignature needs

How to fill out roller chain drive components

How to fill out roller chain drive components

Who needs roller chain drive components?

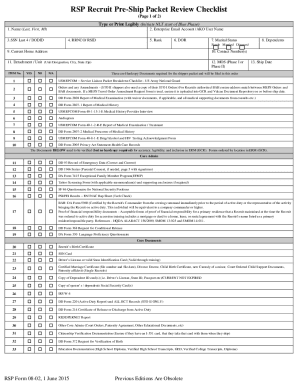

Roller Chain Drive Components Form

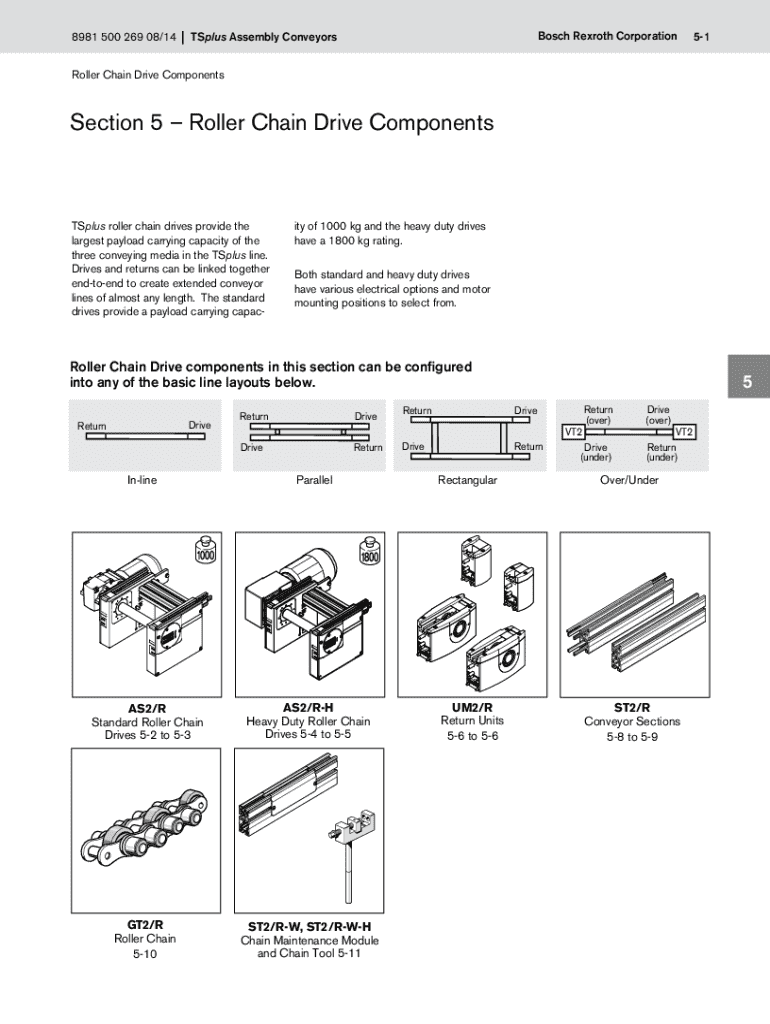

Understanding roller chains: An overview

Roller chains are a crucial component in mechanical systems, facilitating power transmission in various applications. A roller chain consists of a series of interconnected links, designed to transfer rotational power between sprockets. This highly efficient system is predominantly used in industrial machinery, cycles, and conveyor systems, making it an essential element in engineering.

The importance of roller chains in power transmission cannot be overstated. They offer durability and reliability, managing heavy loads while keeping operational costs low. Their modularity allows for easy adjustments and maintenance, thus enhancing their lifespan and performance in various environments.

Components of a roller chain: Detailed breakdown

Roller chains consist of several key components that work together seamlessly. Each part contributes to overall performance, strength, and durability.

Outer link plate

Outer link plates are crucial for the structural integrity of the chain. They connect the chain links and transfer the load during operation. The design incorporates width and thickness to optimize strength while minimizing weight.

Inner link plate

Inner link plates play a significant role in overall chain strength. They are designed to make solid contact with the pins and provide additional support to the overall structure. Manufacturing processes often involve heat treating for enhanced durability.

Chain pin

Chain pins are critical for maintaining the integrity of the chain structure. They serve as pivot points for the links, allowing for smooth movement. Various types and specifications exist depending on the intended application.

Chain roller

Different roller types impact performance and longevity. Standard rollers provide excellent support for power transfer, while specialized rollers may be designed for unique environments, such as high-speed applications.

Bushing

Bushings are essential for reducing friction between the pin and roller. The material used for bushings should be resistant to wear and able to withstand the operational environment. Options such as stainless steel or other wear-resistant materials are common.

Pins and connecting links

Connecting links provide an essential mechanism for chain assembly. Their variants may include quick-connect options for easy maintenance and adjustment.

Roller link - inner link

Roller links consist of an inner and outer link plate and play a key role in the chain's operational efficiency. Regular maintenance, including checks for wear and alignment, ensures optimal performance.

Roller chain subassemblies: Configurations and uses

Understanding roller chain subassemblies enables users to customize configurations for specific applications. The modular nature of roller chain components allows for various combinations tailored to meet distinct operational demands.

For instance, in a conveyor system, a double-pitch roller chain might be used to handle lighter materials, while a heavy-duty variant is essential for transporting heavier loads. Customizable solutions not only enhance performance but also extend the lifespan of the equipment.

Assembling a roller chain: Step-by-step guide

Assembling a roller chain requires precision and attention to detail. Following a systematic approach ensures longevity and functionality.

Step 1: Preparing components

Identifying the necessary tools is a crucial first step. Having snap-ring pliers, chain tools, and proper safety gear on hand helps prevent injuries during assembly.

Step 2: Linking the components

Begin linking components by aligning the outer plates with the pins, ensuring they slide into place smoothly. It's vital to pay attention to alignment and consistency for optimal performance.

Step 3: Testing the assembled chain

Once the chain is assembled, performing necessary checks is essential. Verify tension and alignment, making any adjustments as required. Timely quality control measures help in identifying any potential issues before deployment.

Maintenance of roller chain components

Regular maintenance is essential for ensuring the longevity of roller chain components. A robust inspection routine coupled with effective lubrication practices can mitigate wear and prevent costly downtime.

Inspection routines should focus on key aspects such as tension, alignment, and the condition of components. Noticing signs of wear or excessive play in the chain can prompt timely replacements, ensuring optimal performance.

Choosing the right roller chain for your needs

Selecting the appropriate roller chain involves assessing the specific load requirements and understanding influencing factors such as speed, environment, and compatibility with sprockets.

Different types, such as ANSI and Metric, have distinct properties that can be beneficial based on the application's demands. Heavy-duty chains may be necessary for rigorous conditions while lighter chains suffice for less demanding situations.

Roller chain sizing: How to measure and select

Accurate measurement is critical when sizing roller chains. Techniques often involve determining the length, pitch, and overall dimensions to ensure compatibility with equipment.

Consulting sizing charts for ANSI and Metric chains simplifies the process. Professionals will note that the count of links and pitch directly impacts performance and should be chosen based on the application’s requirements.

Specialized roller chains: Exploring variants

In addition to standard roller chains, there are specialized variants designed for specific uses. Heavy-duty roller chains cater to increased load-bearing requirements, and double pitch chains are beneficial for applications involving higher speeds.

Chains with attachments provide flexibility for unique needs, while unique designs serve industries like food processing or manufacturing, demonstrating the adaptability of roller chains in diverse environments.

Additional tools and resources for roller chain management

Leveraging interactive tools such as sizing calculators and custom chain assembly configurators can streamline the process of selecting and managing roller chains. These tools are designed to support users in making informed decisions.

Filling out the roller chain drive components form is simplified with the use of pdfFiller. This platform allows users to edit, sign, and manage paperwork seamlessly, enhancing productivity and organization in documentation.

Industry insights and trends in roller chain technology

Recent advancements in material science have led to more robust roller chains, catering to evolving industrial needs. Innovations such as coated chains resist wear better than traditional materials, while design trends focus on enhancing efficiency and extended lifespans.

As automation progresses, the future of chain drive mechanisms is moving towards smarter systems integrated with predictive maintenance technologies, ensuring reliability and minimizing downtime across industries.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make changes in roller chain drive components?

How can I fill out roller chain drive components on an iOS device?

How do I complete roller chain drive components on an Android device?

What is roller chain drive components?

Who is required to file roller chain drive components?

How to fill out roller chain drive components?

What is the purpose of roller chain drive components?

What information must be reported on roller chain drive components?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.