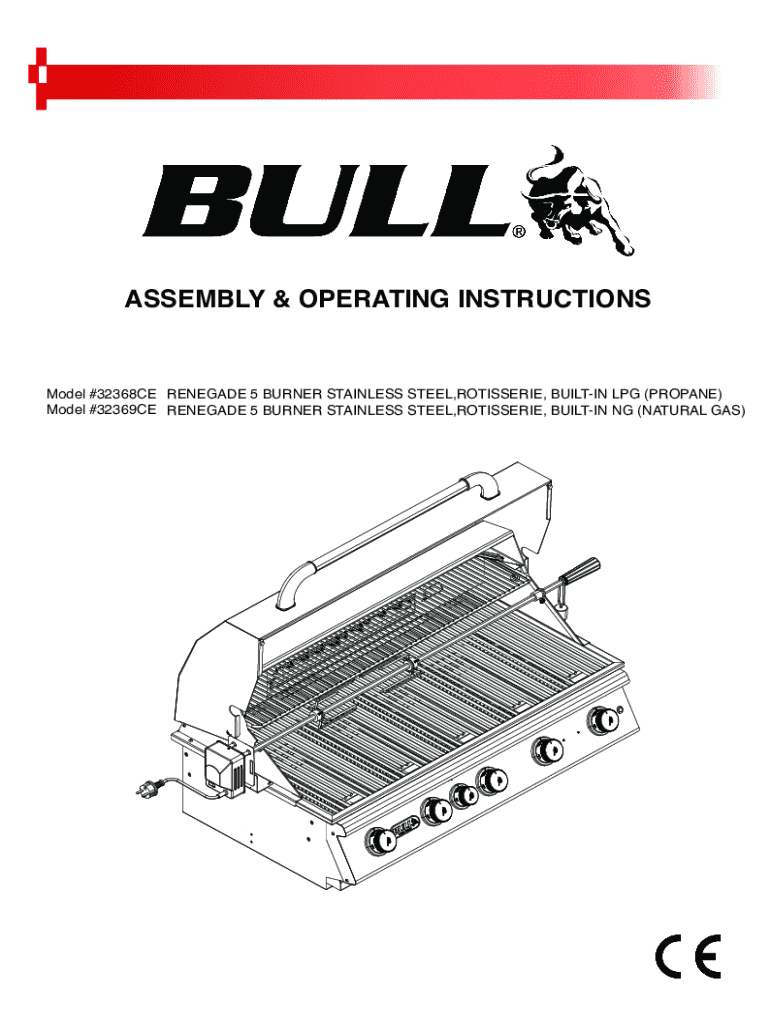

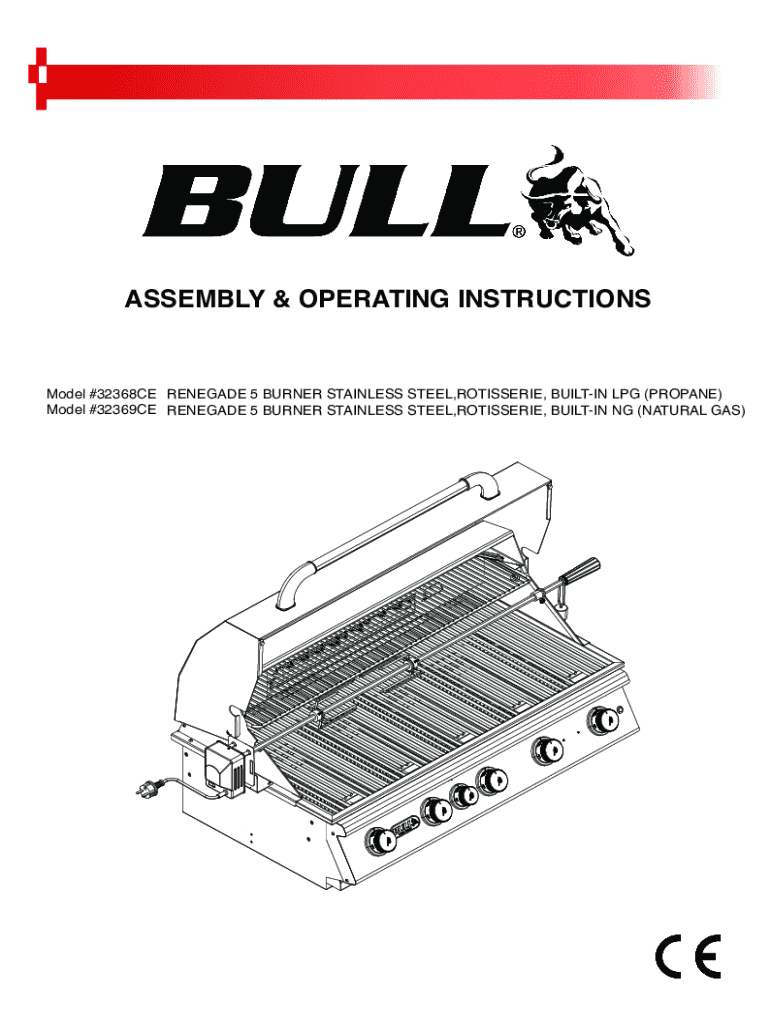

Get the free Assembly & Operating Instructions

Get, Create, Make and Sign assembly operating instructions

How to edit assembly operating instructions online

Uncompromising security for your PDF editing and eSignature needs

How to fill out assembly operating instructions

How to fill out assembly operating instructions

Who needs assembly operating instructions?

Assembly Operating Instructions Form: A Comprehensive Guide

Understanding the assembly operating instructions form

An assembly operating instructions form is a detailed document designed to provide clear and concise guidance on how to assemble a specific product or component safely and effectively. The primary purpose of this form is to ensure that individuals and teams can follow consistent, standardized instructions to achieve high-quality assembly outcomes. This documentation is particularly important in industries such as manufacturing, construction, and logistics, where precision and safety are paramount.

The importance of having a standardized assembly operating instructions form cannot be understated. It not only helps streamline the assembly process but also protects against potential safety hazards by ensuring compliance with safety regulations. By utilizing a consistent format, companies can minimize errors, improve training processes, and enhance overall productivity.

Benefits of using a digital format

Transitioning to a digital format for the assembly operating instructions form, like those offered by pdfFiller, provides several significant advantages. First and foremost, a digital form enhances accessibility and ease of use for team members who may be working remotely or in various locations. Unlike traditional paper formats, digital forms can be accessed and edited from any device with an internet connection, ensuring that the latest version of the instructions is always available.

Additionally, PDF formats streamline document sharing, as they maintain formatting and can be compressed for quicker uploads and downloads. This format also allows for interactive elements, such as fillable fields, which make it easier for users to input specific information and customize instructions according to their particular assembly tasks.

Key components of the form

The assembly operating instructions form contains several critical components that ensure clarity and comprehensiveness. First is the title and identification section, which includes the document title, version number, and the date of creation or revision. This helps users quickly identify the purpose and relevance of the form.

Next, the step-by-step assembly procedures section outlines the exact instructions needed to assemble the product. This is typically presented in a logical, sequential format, using bullet points or numbered steps to enhance readability. Furthermore, safety warnings and precautions must be prominently displayed to inform users about potential hazards and ensure their well-being during the assembly process.

Interactive elements within the form

The inclusion of interactive elements within the assembly operating instructions form provides significant advantages for users. Fillable fields allow individuals to customize the form by adding specific data related to their assembly tasks. This feature is particularly useful for documenting any changes or notes that may arise during the assembly process.

Additionally, embedded instructions and tooltips can enhance clarity by providing additional context for each assembly step. This helps users understand the nuances of the assembly procedures and reduces the likelihood of making errors.

How to fill out the assembly operating instructions form

Filling out the assembly operating instructions form systematically ensures accuracy and consistency. Here’s a step-by-step guide to completing the form:

Here are a few tips for ensuring accuracy and compliance: double-check assembly instructions for completeness and clarity, and keep up with industry standards and regulations to ensure ongoing compliance. Regular updates to the form are essential to adapt to any changes in assembly procedures or safety guidelines.

Editing the form for personal or team use

Editing the assembly operating instructions form using a platform like pdfFiller enhances flexibility for both individual and team use. You can easily access the form via the cloud, allowing edits from any location at any time. This accessibility ensures that all team members can contribute to the completion and accuracy of the assembly instructions.

Various editing tools are available to customize the form as per your requirements. Users can add text, images, and annotations, enhancing the visual appeal and functionality of the document. Additionally, collaboration features allow multiple users to provide input and feedback seamlessly, fostering greater teamwork and enhancing the overall quality of the assembly instructions.

Signing the assembly operating instructions form

After completing the assembly operating instructions form, adding a digital signature is a crucial step for validation. A signature not only authenticates the document but also serves as a compliance measure to ensure that all involved parties agree to the assembly instructions provided.

Using pdfFiller, adding a digital signature is simple and straightforward. Users can easily navigate to the signature field, select options for creating their signature, and place it directly onto the document. This process guarantees that all eSignatures comply with legal requirements, ensuring that your documents are secure and valid.

Managing your assembly operating instructions form

Proper management of your assembly operating instructions form is equally important as its creation. Storing the document using cloud storage solutions allows for easy access across devices and ensures that it can be retrieved quickly when needed. Moreover, maintaining comprehensive folders for different projects or areas of assembly can further streamline your workflow.

When sharing the form with team members or stakeholders, using features like shared links or collaborative permissions can enhance communication. Additionally, best practices for document management include organizing forms for quick retrieval, implementing version control systems, and tracking document history to ensure you always work with the most up-to-date instructions.

Troubleshooting common issues

Common challenges may arise when using the assembly operating instructions form, but understanding how to troubleshoot these issues can save time and frustration. One typical problem is encountering formatting errors while editing the document. If formatting doesn't appear as expected, it may help to reset the text formatting or use standardized styles provided by pdfFiller.

Similarly, users may face difficulties with digital signatures or eSignatures not appearing correctly. In such cases, checking the signature settings and ensuring all necessary fields are filled can resolve most issues. For more complex problems, seeking help through pdfFiller's support services or community forums can provide valuable resources and assistance.

Real-world applications of the assembly operating instructions form

The assembly operating instructions form has been successfully implemented across various industries, demonstrating its adaptability and effectiveness. In manufacturing, for instance, detailed assembly instructions reduce the likelihood of errors during production and enhance overall efficiency. Similarly, in logistics, precision in assembly instructions ensures that products are correctly packaged and shipped.

Case studies also illustrate how construction teams effectively rely on assembly operating instructions forms for assembly tasks, ensuring that all workers adhere to safety protocols and enacted assembly techniques. User feedback consistently emphasizes the role of platforms like pdfFiller in simplifying this process, reducing operational delays, and improving team collaboration.

Additional features and tools

Exploring the more advanced functionalities of pdfFiller can enhance users' experiences with the assembly operating instructions form. Integration capabilities with various software tools, such as project management applications or inventory solutions, helps organizations streamline their processes even further.

Customizability is another significant feature, allowing teams to tailor assembly instructions according to specific industry needs, ensuring that all unique requirements and regulations are met. These additional features contribute to a more fluid, dynamic, and productive approach to managing assembly tasks.

FAQs about assembly operating instructions form

As with any specialized documentation, users may have common questions regarding the assembly operating instructions form. For instance, to reset or recover a document, users can use the recovery features integrated within pdfFiller, which allows retrieval of previously saved versions.

Another frequently asked question involves actions to take if errors are found post-submission. In most cases, users can edit and resend the form, but awareness of best practices for conducting regular updates and reviews is key. Keeping assembly instructions current and compliant is vital for organizational efficiency and safety.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute assembly operating instructions online?

Can I sign the assembly operating instructions electronically in Chrome?

How do I edit assembly operating instructions on an Android device?

What is assembly operating instructions?

Who is required to file assembly operating instructions?

How to fill out assembly operating instructions?

What is the purpose of assembly operating instructions?

What information must be reported on assembly operating instructions?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.