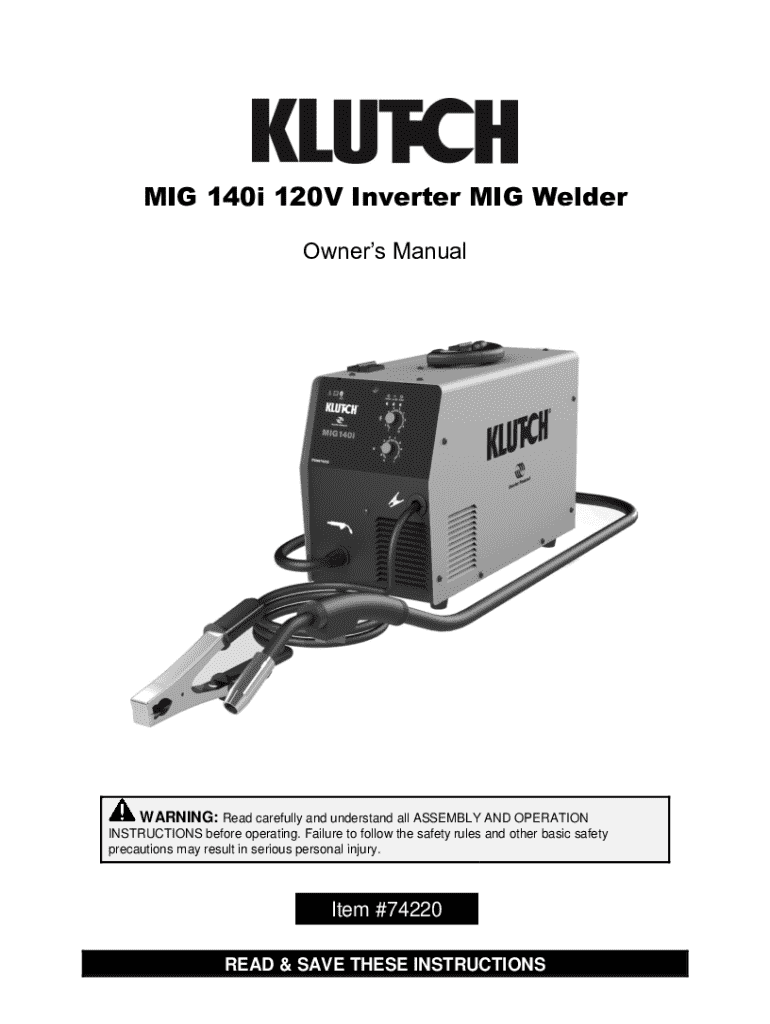

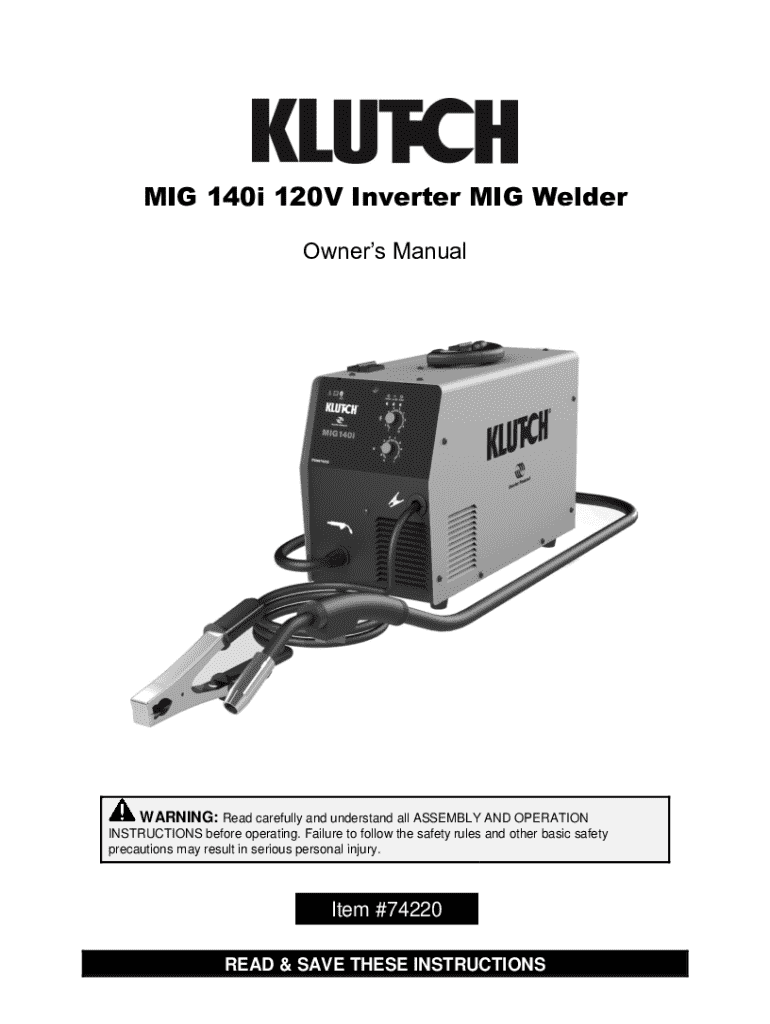

Get the free Mig 140i 120v Inverter Mig Welder Owner’s Manual

Get, Create, Make and Sign mig 140i 120v inverter

Editing mig 140i 120v inverter online

Uncompromising security for your PDF editing and eSignature needs

How to fill out mig 140i 120v inverter

How to fill out mig 140i 120v inverter

Who needs mig 140i 120v inverter?

MIG 140i 120V Inverter Form: A Comprehensive Guide

Understanding the MIG 140i 120V Inverter

The MIG 140i 120V inverter is an advanced welding machine designed for efficiency and versatility. This compact device harnesses modern inverter technology, allowing for precise control over weld quality and ease of use, even for beginners. Its primary purpose is to facilitate Metal Inert Gas (MIG) welding, which is widely used in various industries due to its straightforward technique and adaptability.

MIG welding technology employs a continuous solid wire electrode that is fed through a welding gun while simultaneously shielding the weld area from atmospheric contamination using an inert gas. This results in clean, high-quality welds, making the MIG 140i 120V inverter ideal for both professional fabricators and hobbyists alike.

Key features of the MIG 140i 120V Inverter

One of the standout features of the MIG 140i 120V inverter is its compact design. This portability makes it easy to use in a variety of locations, from home workshops to on-site projects. With dual voltage capability, it allows for operation on standard 120V outlets while also giving the flexibility of connecting to a 240V supply for heavier tasks if needed. This adaptability boosts its practicality across different tasks.

User-friendly controls are another significant asset. The MIG 140i includes intuitive settings that can be easily adjusted based on material thickness and welding speed requirements. Built-in power settings and digital displays enhance usability, allowing even novices to achieve professional results quickly.

Selecting the right MIG 140i 120V inverter for your needs

The MIG 140i 120V inverter excels in various applications, making it an excellent choice for many users. For home repair and maintenance, it easily handles minor fixes and general fabrication tasks. Artists and crafters can utilize its capability for creating intricate metalwork, while automotive repairs benefit from the precision and reliability that this machine offers.

When compared to other welders, the MIG 140i stands out due to its effectiveness and cost-efficiency. Many entry-level MIG welders may compromise on features, but this compact inverter provides higher performance without a hefty price tag, ensuring that users obtain great value in terms of both initial investment and operational costs.

Essential specifications of the MIG 140i 120V inverter

When selecting the MIG 140i 120V inverter, several technical specifications are crucial. The duty cycle often indicates the machine's performance reliability; typically, a duty cycle of 30% at 90A is common for such devices, allowing for extended use without overheating. The amperage range is also an important factor; the MIG 140i generally operates between 30 to 140 amps, which provides flexibility for different welding tasks.

Safety is paramount when dealing with welding equipment. The MIG 140i features built-in voltage protection to safeguard against potential surges and outages, ensuring user safety. It is also compliant with various industry standards, providing assurance of its reliability and performance during use.

Setting up your MIG 140i 120V inverter

Unpacking your MIG 140i is the first step in setting up. Upon opening the box, you'll typically find the inverter itself, an attached welding gun, ground clamp, and instruction manual. It is essential to inspect each component carefully for any signs of damage or defects that might affect performance.

For a successful setup, choose a proper workspace that is clean, well-ventilated, and free from flammable materials. Begin by connecting the power supply, ensuring that it is securely plugged into a suitable outlet. If required, set up gas lines, attaching the regulator to the gas cylinder. A test run after all connections are made will help ensure everything is functioning properly; adjustments may also need to be made to calibrate settings according to specific projects.

Using the MIG 140i 120V inverter effectively

For beginners, mastering basic MIG welding techniques involves understanding your posture and movement. Maintaining a proper stance with feet shoulder-width apart provides a stable foundation. As you maneuver the welding gun, ensuring a steady hand iskey to producing clean, consistent welds. Practicing these techniques on scrap metal reinforces muscle memory and confidence.

Common mistakes to avoid particularly include adjusting welding speed incorrectly. Should you move too slowly, you risk burning through the material; conversely, moving too fast may result in weak, uneven welds. Pre-weld cleaning is also critical; residues like oil or rust can severely impact the quality of your weld, so ensure the surfaces are clean and prepared before beginning your work.

Advanced welding tips for optimal performance

To enhance your welding outcomes, fine-tuning machine settings for different materials is essential. For instance, welding aluminum requires distinct parameters compared to steel due to its thermal properties. Adjusting the feed speed and temperature appropriately can result in stronger bonds and cleaner finishes.

Maintaining consistent weld quality often requires practice. Aim for a steady arc while welding; an inconsistent arc can result in a poor welding bead. Regular practice on scrap materials not only boosts your skillset but also allows you to experiment with settings and techniques without risking your primary projects.

Troubleshooting common issues

When experiencing trouble with your MIG 140i, identifying and addressing common problems is crucial for effective use. If your arc doesn’t ignite, assess the connections in the power supply and check the gas flow. Inconsistent weld beads can stem from fluctuating speed or poor gun angle; troubleshooting here might involve adjusting those aspects and practicing on various materials.

If troubleshooting does not resolve the issues, knowing when to seek professional help is important for safety and efficiency. Regular signs of major malfunctions could include unusual noises, erratic performance, or failure to operate correctly. Accessing customer support and warranty services can ensure any necessary repairs or replacements are handled promptly.

Managing your MIG 140i 120V inverter

Routine maintenance of the MIG 140i ensures longevity and stable performance. Regularly clean the machine to prevent dust accumulation and inspect cables for wear and tear. Proper storage away from moisture and direct sunlight will protect components and maintain their conditions. Routine checks on essential parts like the welding gun and gas connections are recommendable for optimal performance.

Consider upgrading and accessorizing your welder to enhance your welding experience. Suggested add-ons could include specialized welding tips for different material types and upgraded gas cylinders for ideal shielding. When sourcing replacement parts, ensure they are compatible and from reputable suppliers to maintain performance and safety.

Community and support resources

Engaging with fellow welding enthusiasts can greatly enhance your skills and knowledge. Online forums, like those on Reddit, and social media groups provide platforms to exchange tips and project ideas. Additionally, local community workshops and meet-ups can facilitate hands-on experience and networking opportunities.

Utilizing tools like pdfFiller for document management can simplify record-keeping for welding projects and maintenance logs. Keeping user manuals, warranty details, and project files organized in an easily accessible format streamlines collaboration and improves workflow in your welding activities.

Exploring additional learning opportunities

To further develop your welding skills, participate in free training sessions and webinars. These often cover a range of topics from basic techniques to advanced welding practices. Hands-on training can significantly boost your confidence and proficiency, making it an invaluable opportunity for users of all levels.

Numerous educational guides and video resources are available online. Channels focused on DIY projects and technical skills offer free tutorials and structured courses for more in-depth learning. Platforms like YouTube feature expert guidance and practical welding tips, making it easier to seek improvement while engaging with the community.

Safety considerations when using MIG welding equipment

Prioritizing personal safety is essential in any welding operation. Essential personal protective equipment (PPE) should include fire-resistant clothing, gloves, and safety goggles. Proper gear protects against sparks and harmful UV rays generated during the welding process, which can cause serious injuries if precautions are not taken.

Beyond PPE, creating a safe working environment is imperative. Ensure your workspace is well-ventilated to circulate fumes and reduce exposure to harmful gases. Fire safety is also crucial; keep a fire extinguisher nearby and establish clear safety protocols to mitigate risks associated with welding.

Customer feedback and experiences

User reviews of the MIG 140i 120V inverter generally praise its performance and ease of use. Customers have reported successful welding results for a variety of projects, highlighting the machine's reliability and versatility. Testimonials showcase a wide range of applications, further validating the inverter’s adaptability for both beginners and seasoned welders.

Video reviews offer a visual perspective on the setup and usage of the MIG 140i. These walkthroughs often demonstrate real-time performance, providing valuable insights into how the machine operates. Expert reviews posit that the cost-to-benefit ratio is exceptional, making the MIG 140i a favored option among users seeking quality without breaking the bank.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit mig 140i 120v inverter online?

Can I edit mig 140i 120v inverter on an iOS device?

How do I fill out mig 140i 120v inverter on an Android device?

What is mig 140i 120v inverter?

Who is required to file mig 140i 120v inverter?

How to fill out mig 140i 120v inverter?

What is the purpose of mig 140i 120v inverter?

What information must be reported on mig 140i 120v inverter?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.