Get the free News From the Mill

Get, Create, Make and Sign news from form mill

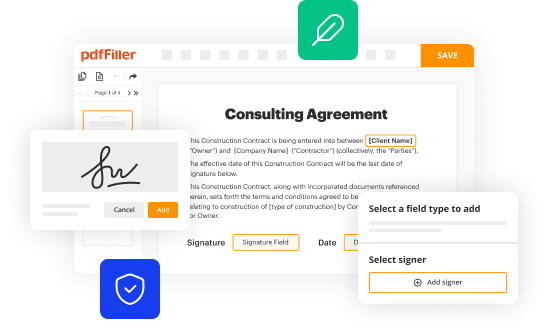

Editing news from form mill online

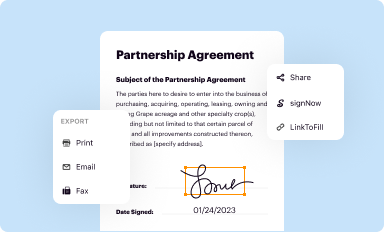

Uncompromising security for your PDF editing and eSignature needs

How to fill out news from form mill

How to fill out news from form mill

Who needs news from form mill?

News from Form Form: A Comprehensive Guide to Form Milling Technology

Understanding form technology

Form milling, a crucial technique in modern manufacturing, specializes in producing complex shapes and profiles in a wide array of materials. This process involves using specialized cutters that can shape workpieces to exact specifications, which is essential for industries demanding high precision.

Key components of form milling

The effectiveness of form milling hinges on critical components such as form mill cutters and machine setup. Form mill cutters, designed with unique geometries, allow for the precision shaping of materials. The configuration of the machine is equally important, as it impacts the overall output quality.

Applications of form milling

Form milling finds its applications across various industries, mainly in aerospace and automotive sectors. These industries require high levels of precision for components that often have complex geometries. Form milling is also widely utilized in manufacturing and industrial applications, where custom shapes are required.

Unique use cases also demonstrate the versatility of form milling. For instance, it is ideal for prototype development, where rapid iterations of designs are necessary. Likewise, custom parts production benefits from form milling's ability to create tailored components efficiently.

Interactive tools for form milling

The advent of digital technologies has introduced numerous interactive tools for form milling. Online calculators and estimators assist manufacturers in assessing project feasibility and resource allocation. 3D visualization tools further enhance design accuracy, allowing for better planning before actual milling begins.

Guidelines for effective form milling

To ensure successful form milling projects, proper preparation is essential. This starts with meticulous material selection and preparation, as the properties of the material influence machining behavior and final product quality. Initial machine settings should also be calibrated for optimal performance.

The step-by-step milling process involves several phases: After setting up the machine, executing the milling operation, and lastly, implementing quality control measures to ensure every piece meets the required specifications.

Advantages of using form mills

Form milling offers several significant advantages that make it a preferred choice among manufacturers. First and foremost, its precision and accuracy in production yield parts that meet stringent specifications consistently. The versatility in part design permits the crafting of unique geometries, making it applicable in various sectors.

Limitations and considerations in form milling

Despite its many benefits, form milling is not without limitations. Common challenges include tool wear, which demands regular maintenance to ensure optimal performance. Additionally, material constraints might limit the types of components that can be efficiently produced.

Cost implications also play a crucial role in budget planning for form milling projects. Accurately estimating expenses requires a comprehensive understanding of all associated costs, from materials to machine operation.

Choosing the right form milling strategy

Selecting the appropriate form milling strategy depends on various factors including design complexity and production volume. Projects involving intricate designs may necessitate more advanced tooling and machine settings than simpler projects.

When comparing form milling with traditional milling methods, it's essential to weigh the pros and cons of each approach. Form milling often delivers better outcomes for complex geometries, while traditional methods may be preferable for simpler tasks.

Future trends in form milling technology

As industries evolve, so does form milling technology. Innovations on the horizon include advancements in cutter design and machine capabilities, which promise enhanced production speeds and quality. Automation and AI are increasingly playing roles in optimizing milling processes, thereby reducing manual labor.

Knowledge enhancements and resources

For those eager to delve deeper into form milling, various resources are available for further education. Books and articles offer foundational knowledge, whereas online courses and workshops present opportunities for hands-on learning.

FAQs also serve as a valuable tool for clarifying common queries regarding form milling, while community forums create spaces for discussion and sharing best practices among professionals.

Getting support for your form milling needs

When you require assistance with form milling, pdfFiller offers consulting services that can guide you through the intricacies of your projects. Accessing interactive support channels ensures that queries are addressed promptly, creating a seamless experience in managing your forms.

Case studies and success stories

Successful applications of form milling through pdfFiller users provide real-world examples of how this technology can be effectively utilized. Case studies illustrate diverse scenarios where companies have benefited from high-precision milling for intricate component production.

Engaging with the community: events and news

The form milling community is active and engaging, hosting various events, webinars, and workshops that keep professionals updated with the latest trends and technology. Participation in industry conferences fosters networking opportunities and collaborations, enriching the collective knowledge base.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for signing my news from form mill in Gmail?

How do I edit news from form mill on an iOS device?

Can I edit news from form mill on an Android device?

What is news from form mill?

Who is required to file news from form mill?

How to fill out news from form mill?

What is the purpose of news from form mill?

What information must be reported on news from form mill?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.