Get the free Introduction to Aircraft Fabrication Application Packet

Get, Create, Make and Sign introduction to aircraft fabrication

How to edit introduction to aircraft fabrication online

Uncompromising security for your PDF editing and eSignature needs

How to fill out introduction to aircraft fabrication

How to fill out introduction to aircraft fabrication

Who needs introduction to aircraft fabrication?

Introduction to Aircraft Fabrication Form

Understanding aircraft fabrication

Aircraft fabrication refers to the process of manufacturing aircraft components, which is a critical step in aircraft assembly and maintenance. It encompasses a range of processes, including the design, engineering, and actual construction of various parts that make up an aircraft. Ensuring precision and adherence to design specifications is paramount in this field, where any flaws can significantly impact safety and performance.

In the aviation industry, aircraft fabrication forms the backbone of reliable air travel. Each component created through fabrication undergoes meticulous scrutiny to ensure that it meets strict regulatory standards. Therefore, the integrity of these components not only supports the aircraft's performance but also plays a vital role in maintaining passenger safety and airworthiness.

Key aircraft components

Essential parts produced in aircraft fabrication include wings, fuselages, control surfaces, and landing gears. Each of these components requires specialized techniques and materials tailored to withstand the unique stresses experienced during flight. For instance, aluminum is commonly used for the structures due to its lightweight properties and resistance to corrosion. Composite materials, such as carbon fiber, have also gained traction in recent years for their strength-to-weight ratios.

Overview of the aircraft fabrication form

The aircraft fabrication form serves a fundamental role in documenting the various stages of fabrication processes. This form acts as a key record-keeping tool that maintains a detailed history of how components were designed, manufactured, and inspected. By ensuring that every step in the fabrication process is documented, organizations can adhere to regulatory guidelines and ensure accountability within the fabrication environment.

Moreover, the integration of this form with quality assurance systems enables organizations to track compliance with industry standards. Accurate documentation can reveal potential issues early in the fabrication process, minimizing costs and enhancing the safety of the final product. Overall, the aircraft fabrication form is not just bureaucratic; it is integral to ensuring the safety and reliability of the aircraft.

Types of aircraft fabrication forms

Depending on the specific aircraft type and components being fabricated, various forms may be required. Standardized forms are used across the industry to create consistency, especially in larger organizations. However, specialized forms tailored to unique parts or manufacturing processes can also exist, allowing companies to meet specific regulatory or operational requirements.

Steps to complete the aircraft fabrication form

Successfully completing the aircraft fabrication form requires careful preparation and attention to detail. Before you even begin filling out the form, gathering all the necessary materials is crucial. This includes design specifications, engineering documents, and relevant industry regulations. Identifying the stakeholders involved in the process is also essential, as their input may be required to ensure completeness and accuracy.

Pre-completion preparation

Once you have all the materials, it's important to review them to understand what information is needed for the form. Whether it's inputting basic data or outlining specific fabrication processes, clarity on each step will facilitate efficient completion of the form. Moreover, engaging with all stakeholders early on will foster collaboration and accountability throughout the process.

Step-by-step instructions for filling out the form

The first step typically involves entering basic information such as the project name, date of completion, and project number. Proper attention to these fields ensures clear tracking of each project from the outset. Next, detailing the fabrication processes is critical. Here, you’ll need to articulate all the steps taken to manufacture each aircraft component along with the materials employed, such as aluminum alloys or composite materials.

Another important step is documenting quality control measures. This could involve recording inspection processes, tests performed, and approvals granted by quality assurance departments. Finally, obtaining signatures and authorizations is non-negotiable for compliance; all relevant stakeholders must sign off on the form to indicate their acknowledgment and acceptance of the documented information.

Common errors to avoid

Even a small mistake on the aircraft fabrication form can lead to significant consequences. Common errors include failing to fill out required fields, which can lead to legal challenges or delays in the approval process. Inaccurately describing fabrication processes or materials used can result in compliance violations and jeopardize safety.

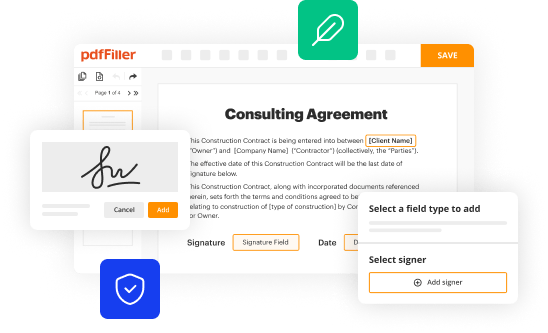

Editing and managing the aircraft fabrication form

Navigating the complexities of the aircraft fabrication form can be streamlined by utilizing tools like pdfFiller. This platform allows users to edit the form seamlessly, ensuring no data is lost throughout the editing process. With a variety of interactive tools available, teams can make updates collaboratively and organize their documentation efficiently. The ability to access and edit forms from anywhere elevates productivity during busy fabrication periods.

Utilizing pdfFiller for editing

pdfFiller stands out as a user-friendly platform designed specifically for document management. With its editing tools, users can make real-time changes to the aircraft fabrication form without taking the risk of losing existing data. This flexibility is particularly valuable when quick updates are needed after inspections or quality audits. The platform's interactive features enhance collaboration, allowing multiple team members to engage in the form simultaneously.

Collaboration features

Team collaboration is made easy with pdfFiller. Users can comment on specific sections of the form and track changes, making it easier to understand updates and integrate diverse inputs from various stakeholders. This collaborative nature not only speeds up processes but also enhances transparency and accountability across teams involved in aircraft fabrication.

Storing and managing documents

The benefit of cloud-based document management cannot be overstated. Teams can store all documentation related to aircraft fabrication forms securely while ensuring easy access for authorized personnel. Storing documents in pdfFiller allows users to organize and retrieve forms rapidly, reducing time lost searching for documents in a physical filing system or disparate drives.

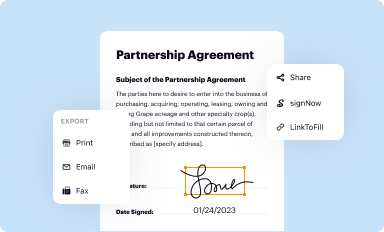

The importance of electronic signatures in aircraft fabrication

Electronic signatures (eSignatures) have become crucial in streamlining the acceptance of documents, including aircraft fabrication forms. They provide a legally accepted method for authorizing documents, enhancing the speed at which forms can be approved and processed. This swift turnaround is essential in industries like aviation, where timelines can be tight and coordination between multiple parties is necessary.

The role of eSigning in compliance

eSignatures are recognized legally under regulations like the Electronic Signatures in Global and National Commerce (ESIGN) Act in the US and the eIDAS Regulation in the EU. Their role in compliance becomes even more pronounced within aviation compliance frameworks, where every document must bear the proper approvals. Utilizing a secure and legally sound method for signing off on aircraft fabrication forms ensures that companies meet their obligations without compromising integrity.

Secure signing process with pdfFiller

pdfFiller facilitates a secure signing process for its users. The platform emphasizes authentication and security during the signing process, ensuring that only authorized individuals can approve the aircraft fabrication forms. The user-friendly interface guides individuals through the eSigning process, from initial setup through final confirmation, promoting efficiency without sacrificing security.

Benefits of using pdfFiller for the aircraft fabrication form

Choosing pdfFiller for aircraft fabrication form management encapsulates several key advantages. One of the standout features is the access-from-anywhere convenience that comes with a cloud-based platform. Whether you’re at the manufacturing facility, in a meeting, or working from home, you can easily access, edit, and sign the documentation needed.

Enhanced collaboration tools

Enhanced collaboration tools provided by pdfFiller allow team members to work together effectively on the same document. With real-time capabilities, individuals can see changes made in the moment, reducing the chances of miscommunication. Moreover, collaborative commenting and approval processes mean that everyone involved can provide input, ensuring the final document reflects all necessary contributions.

Streamlined workflow

By streamlining the workflow associated with aircraft fabrication forms, pdfFiller significantly reduces processing time. Quick edits, easy signing, and centralized document storage mean that teams can focus on what truly matters—maintaining the integrity of the fabrication process while complying with industry regulations. These efficiency gains are vital in a fast-paced field where timing often determines success.

Summary of best practices for aircraft fabrication forms

Quick tips for effective documentation

Effective documentation is paramount when handling aircraft fabrication forms. Ensuring that you include all necessary information, double-check for accuracy, and obtain the required signatures will help maintain compliance and reduce risk. Timeliness is also a critical factor; submitting forms promptly can prevent delays in project timelines.

Utilizing pdfFiller for continuous improvement

Leveraging the tools available on pdfFiller can contribute to continuous improvement efforts. Regularly revisiting and refining how forms are completed, edited, and stored will enhance overall efficiency in the fabrication process. As teams adapt and improve their processes, embracing technology like pdfFiller will ensure they remain at the forefront of industry standards.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my introduction to aircraft fabrication directly from Gmail?

How can I edit introduction to aircraft fabrication from Google Drive?

How do I complete introduction to aircraft fabrication on an iOS device?

What is introduction to aircraft fabrication?

Who is required to file introduction to aircraft fabrication?

How to fill out introduction to aircraft fabrication?

What is the purpose of introduction to aircraft fabrication?

What information must be reported on introduction to aircraft fabrication?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.