Get the free Disc Staple Set Brush Worksheet

Get, Create, Make and Sign disc staple set brush

Editing disc staple set brush online

Uncompromising security for your PDF editing and eSignature needs

How to fill out disc staple set brush

How to fill out disc staple set brush

Who needs disc staple set brush?

Comprehensive Guide to Disc Staple Set Brush Form

Understanding disc staple set brushes

Disc staple set brushes are specialized tools designed for various industrial applications, primarily focused on cleaning, finishing, and surface preparation. These brushes consist of bristles anchored in a disc formation through a staple set method, providing durability and enhanced performance. The unique design allows for an even distribution of pressure, making them ideal for intricate tasks that require precision.

Industries such as automotive, metalworking, and woodworking utilize these brushes for tasks ranging from deburring edges to cleaning surfaces prior to coating. Their significant advantages include long service life, reduced vibration during operation, and versatility across numerous applications.

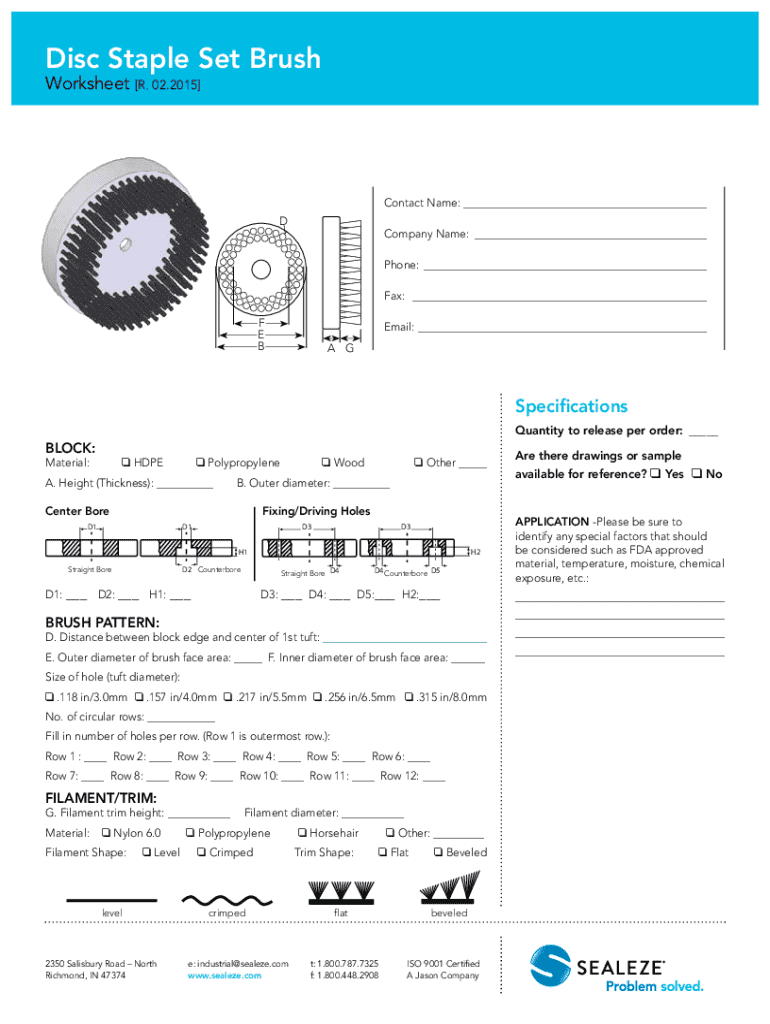

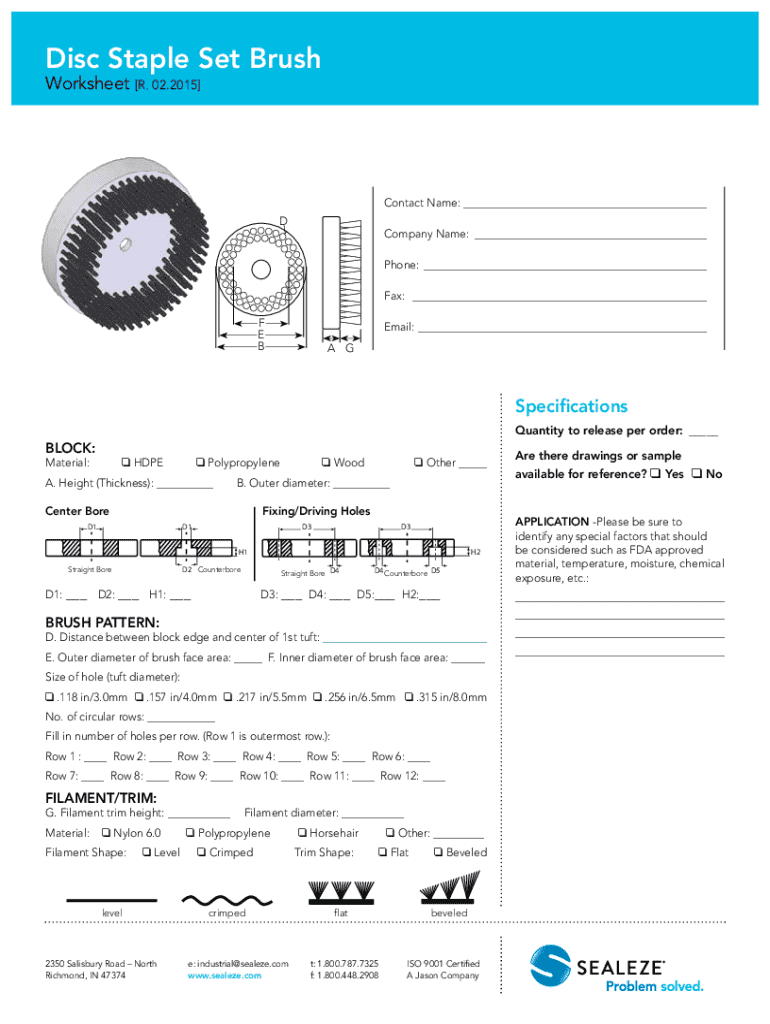

Components of a disc staple set brush

A disc staple set brush consists of several integral components that contribute to its effectiveness. The structure typically includes a central hub where the bristles are attached. The base material, which can be metal or plastic, holds the bristles firmly in place. It is essential for ensuring that the brush maintains its integrity during operation.

The filling materials vary widely, from nylon and steel to natural fibers, allowing users to select bristles based on their specific abrasive needs. Additionally, the design of the holes through which the bristles are set can greatly affect performance. Factors such as hole diameter and pattern influence brush effectiveness:

Customizing your disc staple set brush

Customization in disc staple set brushes is paramount for optimized performance tailored to specific tasks. The flexibility to modify shapes, sizes, and filling densities ensures that users get the most out of their equipment. Parameters such as texture, flexibility, and abrasive properties can profoundly influence the outcome of the job.

A few customization options include:

To design a custom brush, follow these steps: Evaluate your needs based on the task at hand, choose your brush specifications carefully, and submit a design request to a trusted manufacturer.

Filling techniques for disc staple set brushes

Filling techniques applied in disc staple set brushes significantly impact their effectiveness. Straight filling and angled filling are two predominant methods, each presenting distinct advantages. The selection depends on the specific application and desired finish.

A comparative analysis of filling patterns may reveal the following insights:

Specialty designs and variations

Advanced designs and variations of disc staple set brushes cater to specialized tasks. Users have options like flat trims for a basic finish and bevel trims for more nuanced requirements, enabling selection based on the project's intricacies.

Concave and convex trims provide unique advantages for different surface geometries, while spiral and chevron patterns can significantly reduce drag and improve the efficiency of material removal. These specialty designs suit unique applications, such as:

Product categories related to disc staple set brushes

Disc staple set brushes are part of a broader category of brush tools. Modular systems enhance customization capabilities, allowing for quicker modifications suited to various uses. Key related brush types include cylinder brushes and wheel brushes, each possessing unique characteristics.

A brief overview of these categories can guide you in selecting complementary tools for your operations:

Maintenance and care for disc staple set brushes

Proper maintenance is essential to maximize the lifespan and efficiency of a disc staple set brush. Regular checking for wear and tear can prevent reduced performance and costly replacements later on.

Best practices for upkeep include:

Common troubleshooting issues include bristle loss and uneven wear, which can be mitigated by adhering to these maintenance guidelines.

Innovative applications of disc staple set brushes

Unique applications demonstrate the versatility of disc staple set brushes, showcasing their role in improving production efficiency across multiple sectors. Detailed case studies highlight how companies leverage these tools to optimize operations.

Innovative uses include:

As industries evolve, future trends indicate a persistent shift towards multifunctionality in brush design, accommodating a wider range of applications.

Interactive tools and resources

Various resources are available to assist users in finding the right disc staple set brush and designing custom solutions. Designing tools can streamline the customization process, ensuring optimal performance tailored to individual needs.

Helpful resources include:

Frequently asked questions (FAQ)

Addressing common inquiries provides clarity and aids in the decision-making process for users considering disc staple set brushes. Typical questions focus on customization options, application suitability, and maintenance practices.

Common FAQs include:

Contact and support options

For assistance, users can contact customer service to address technical questions regarding disc staple set brushes. Access to personalized assistance ensures tailored solutions to suit individual requirements.

Typical support options available include:

Getting started with your disc staple set brush

Selecting the right disc staple set brush is critical for achieving optimal results. A well-structured checklist can streamline the selection process, ensuring no essential parameters are overlooked.

Your path to customization and ordering involves:

Maximizing the benefits of your new brush relies on understanding its features and applying it accordingly. Engage with manufacturer resources for continuous learning.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit disc staple set brush online?

How do I edit disc staple set brush on an iOS device?

Can I edit disc staple set brush on an Android device?

What is disc staple set brush?

Who is required to file disc staple set brush?

How to fill out disc staple set brush?

What is the purpose of disc staple set brush?

What information must be reported on disc staple set brush?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.