Get the free INJECTION. Label

Get, Create, Make and Sign injection label

Editing injection label online

Uncompromising security for your PDF editing and eSignature needs

How to fill out injection label

How to fill out injection label

Who needs injection label?

Injection Label Form - A Comprehensive Guide

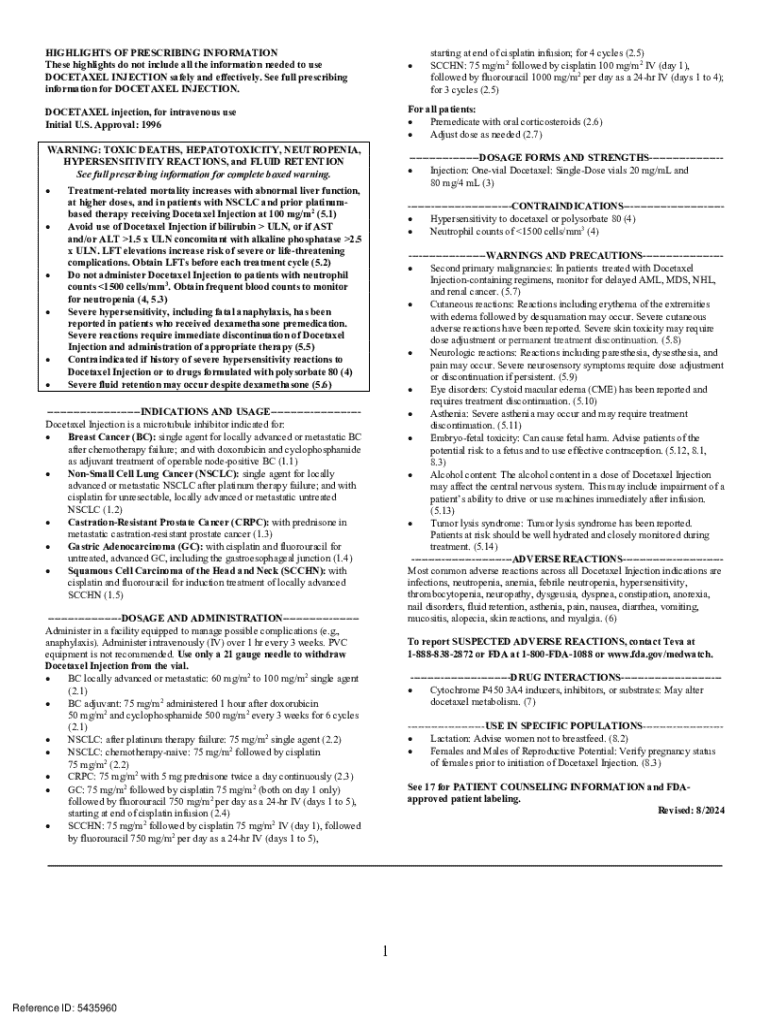

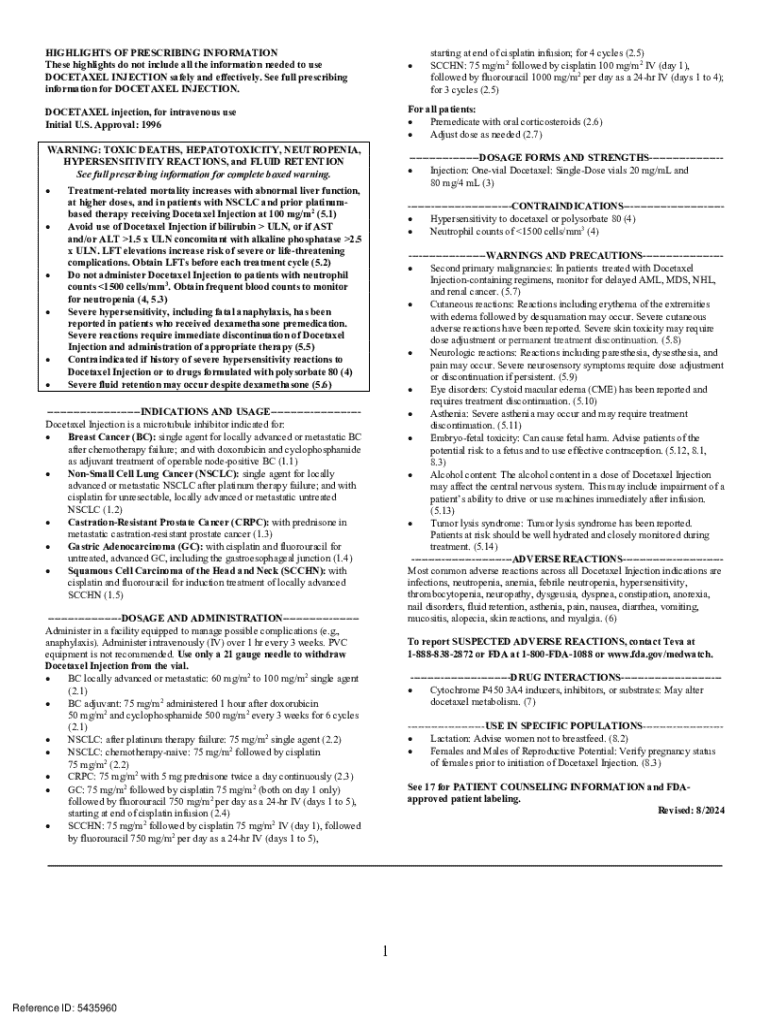

Understanding injection labels

Injection labels are critical documentation that accompanies injectable medications, ensuring accurate usage and safety. They communicate essential information to healthcare professionals and patients alike, detailing what the injection is, how to use it, and any necessary precautions. Effective labeling can prevent medical errors, enhance patient safety, and ensure compliance with regulatory standards.

There are several types of injection labels, each tailored to the specific form of medication delivery. These include:

Regulatory standards governing injection labels are rigorous, ensuring that all critical information is included and clearly presented. These standards vary by country and type of medication, but they all prioritize patient safety and effective communication.

Key features of effective injection labels

An effective injection label contains vital information such as the name of the medication, dosage instructions, route of administration, storage conditions, and expiration date. Additionally, it should include safety warnings and information regarding side effects to ensure comprehensive guidance for the user.

Labeling formats should adhere to best practices, guaranteeing readability and clarity. Visual elements such as color coding and icons can enhance quick recognition, helping healthcare professionals and patients alike to access critical information rapidly. For instance, green could signify safe use, while red may indicate critical warnings.

User safety is paramount. Incorporating tamper-evident technologies is essential to protect against unauthorized access and ensure product integrity from manufacturing through to the end-user.

Challenges in injection labeling

Creating injection labels that perform well under extreme conditions can be challenging. Whether in high humidity or low temperatures, labels must not only remain legible but also adhere securely to vials or syringes over time.

Ensuring legibility and printability is vital, with changes in environmental conditions including exposure to chemicals or mechanical stresses often compromising label integrity. Moreover, low leachability and biocompatibility considerations must be made to avoid interactions between the label materials and the injectable products.

Material selection for injection labels

Selecting the right label material is crucial. Labels need to be durable enough to withstand a variety of storage conditions. They must be made from fungible and biocompatible materials to ensure patient safety and product integrity.

Low migration labels are recommended, preventing any transfer of label material into the injectable solution. Testing label materials for compatibility is essential, with considerations for different storage scenarios such as refrigeration, freezing, or cryogenic environments.

In addition to ensuring compatibility with the medication, proper sterilization techniques must be employed, as certain methods can affect label performance and readability.

Pre-testing and quality assurance of labels

Pre-testing label solutions is imperative in the injection labeling process. This involves rigorous testing methods such as mandrel hold tests that simulate real-world conditions in which the labels will be used. Such testing ensures that labels maintain their clarity, adhesion, and overall integrity under expected conditions.

Several case studies highlight successful label implementations, showcasing tangible results where accurate labeling significantly reduced errors and improved patient outcomes. Verifying label presence during production also plays a critical role in maintaining quality assurance.

Innovative solutions in injection labeling

The integration of smart technologies into injection labeling is paving a new path for enhanced safety and tracking. Smart NFC technology can allow healthcare providers to access product information with a simple tap of their smartphones, offering an immediate overview of crucial data from dosages to storage requirements.

Additionally, Pharma-RFID technology is emerging as a powerful tool for efficient tracking, allowing for real-time updates on inventory and ensuring that medications can be promptly located. This integration ensures better management of medications, ultimately benefiting patient care.

Moreover, interactive labeling can enhance patient support by including QR codes or links to online resources that provide step-by-step instructions or support for users and healthcare professionals.

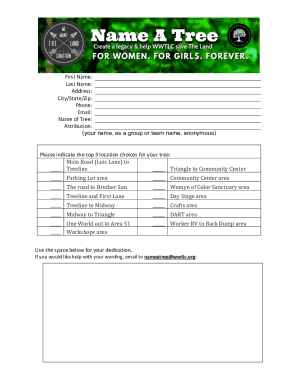

Designing custom injection labels with pdfFiller

Creating custom injection labels is streamlined with pdfFiller. The platform allows users to select from a library of templates and customize them to meet their specific needs. This ensures that all compliance information and user instructions are accurately represented.

Steps include template selection and customization, where essential details such as dosage and expiration information can be easily added. Additionally, pdfFiller’s collaboration features facilitate edits and discussions among team members, promoting efficiency throughout the design process.

Beyond creating labels, pdfFiller supports e-signing and integrates seamlessly with document management systems, providing a comprehensive solution for all labeling needs.

Ensuring compliance with standards and regulations

Adhering to compliance guidelines is crucial in injection labeling. Familiarity with necessary regulations, such as FDA guidelines in the U.S. or European Medicines Agency standards in Europe, ensures that labeling fulfills governmental requirements.

A checklist for verifying injection label compliance may include reviewing label accuracy, ensuring all required information is present, and checking for legibility. Addressing common challenges in maintaining compliance, such as staying updated with changing regulations, is also essential to ensuring the effectiveness of labeling efforts.

Future trends in injection labeling

As technology evolves, so do strategies in injection labeling. Smart packaging solutions are emerging on the horizon, set to incorporate features such as real-time monitoring of temperature and storage conditions. These advancements will facilitate a higher level of safety and quality assurance.

Innovations in label materials and technologies promise even more flexibility, allowing for dynamic adherence to regulatory standards. Anticipating changes in regulatory requirements will be critical for pharmaceutical companies, ensuring that they keep pace with expectations and maintain the highest standards of patient safety.

Integration of patient safety features in injection labels

Patient safety is paramount in injection labeling. Additional functions, such as bold warnings, visual indicators, and easy-to-follow instructions, can be implemented to ensure medication compliance and lessen misuse risks.

To implement patient-centric label solutions, providers can engage patients in the labeling process, gathering feedback to understand their needs better. Addressing potential pain points can lead to designs that not only inform but also empower users.

Technical information for professionals

For further inquiries or support regarding injection labels and their production, professionals can reach out to pdfFiller’s dedicated support team. Comprehensive documentation and resources are also available to assist with any labeling needs, ensuring a smooth and efficient process.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my injection label in Gmail?

How do I edit injection label online?

How do I complete injection label on an Android device?

What is injection label?

Who is required to file injection label?

How to fill out injection label?

What is the purpose of injection label?

What information must be reported on injection label?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.