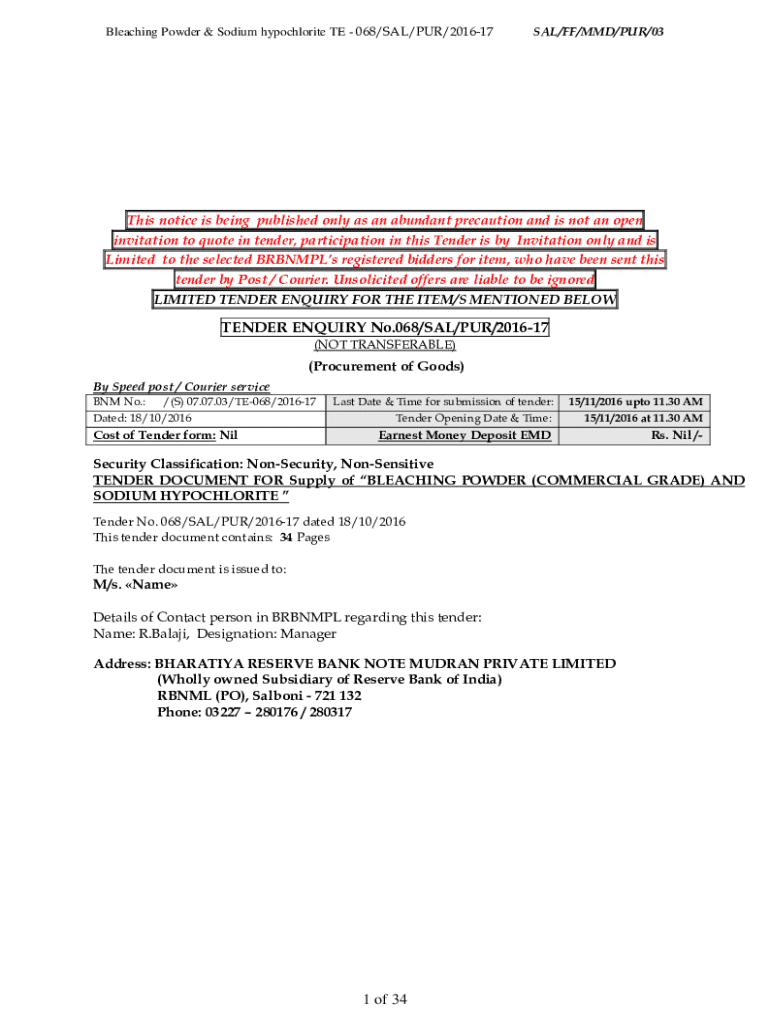

Get the free Bleaching Powder & Sodium Hypochlorite Te - 068/sal/pur/2016-17

Get, Create, Make and Sign bleaching powder sodium hypochlorite

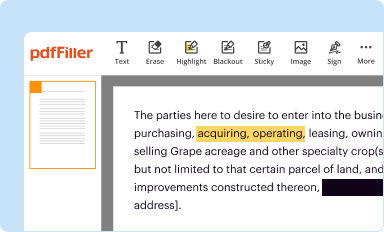

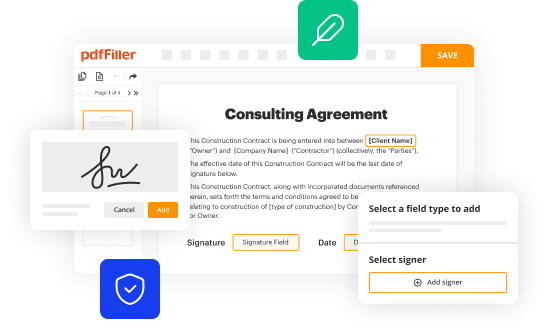

How to edit bleaching powder sodium hypochlorite online

Uncompromising security for your PDF editing and eSignature needs

How to fill out bleaching powder sodium hypochlorite

How to fill out bleaching powder sodium hypochlorite

Who needs bleaching powder sodium hypochlorite?

Bleaching Powder Sodium Hypochlorite Form: Comprehensive Insights and Applications

Understanding sodium hypochlorite

Sodium hypochlorite, often referred to as bleach, is a widely used chemical that serves multiple purposes, particularly in sanitation and cleaning. Its molecular formula is NaOCl, comprising sodium (Na), oxygen (O), and chlorine (Cl). In its concentrated form, it appears as a pale yellowish liquid with a strong chlorine odor. Sodium hypochlorite's reactivity and oxidative potential make it a powerful disinfectant.

Historically, sodium hypochlorite was first discovered in the early 18th century by French chemist Claude-Louis Berthollet. It gained practical importance as a bleaching agent in the textile industry during the 19th century. Its use expanded over the years to include disinfection in healthcare settings, demonstrating its versatility and effectiveness.

Production of sodium hypochlorite

The production of sodium hypochlorite primarily involves two industrial processes. The first is the electrolysis of saltwater, where sodium chloride (table salt) is dissolved in water and subjected to electrical current, separating it into sodium hydroxide and chlorine gas. The second process involves reacting chlorine gas with sodium hydroxide, yielding sodium hypochlorite as a final product. This method is often favored due to its efficiency and lower costs.

Another method involves converting calcium hypochlorite to sodium hypochlorite through a simple chemical process involving sodium hydroxide. Quality control is crucial throughout these production stages to ensure compliance with health and safety standards, as well as to maintain the product's potency and effectiveness.

Packaging and sale of bleaching powder

Sodium hypochlorite is available in various forms, primarily in liquid and solid formats. The liquid form is most common in household bleach, while solid bleaching powder is often used in industrial applications. The packaging of sodium hypochlorite needs to prioritize safety and stability, commonly utilizing polyethylene or glass containers that can withstand corrosive substances.

Labeling is equally vital, requiring clear instructions regarding hazards, dilution ratios, and handling precautions to ensure safety for consumers. Best practices in packaging not only protect the product but also keep the users informed.

Applications of sodium hypochlorite

Sodium hypochlorite serves a variety of applications across different sectors. In households, it is primarily used for cleaning and disinfecting surfaces, removing stains, and in laundry as a whitening agent. Many homes benefit from its properties in eliminating mold and mildew from bathrooms and kitchens.

Industrially, sodium hypochlorite plays a critical role in wastewater treatment processes by effectively killing bacteria, fungi, and viruses, thus ensuring safe water is released back into the environment. Additionally, in food processing, it helps maintain hygiene standards by sanitizing equipment and surfaces, thereby preventing contamination.

Other notable uses include endodontic procedures in dentistry due to its antibacterial properties and its widespread use in hospitals for disinfecting surfaces, instruments, and patient areas, significantly reducing infection rates.

Safety precautions

While sodium hypochlorite is a powerful disinfectant, it poses several health hazards. When inhaled or in contact with skin, it can cause respiratory issues, skin irritation, or even chemical burns. Proper personal protective equipment (PPE) such as gloves, goggles, and masks is essential when handling this chemical.

Safety in handling includes following strict guidelines for storage. Sodium hypochlorite should be stored in a cool, dry place away from incompatible substances like acids, which can lead to the release of harmful gases. In the event of spills, appropriate emergency procedures should be in place to minimize exposure and environmental impact.

In case of skin or eye contact, it is crucial to flush the area with plenty of water and seek medical attention immediately. Ensuring readiness for emergencies can save lives and mitigate risks associated with misuse.

Environmental impact of sodium hypochlorite

Sodium hypochlorite decomposes into various byproducts, the most common being chloride salts and oxygen. While these are generally less harmful, the chemical can react with organic materials in water bodies, potentially forming harmful compounds such as dioxins. Therefore, understanding its breakdown and environmental consequences is essential in all applications.

To minimize environmental impact, several regulations exist governing the use and disposal of sodium hypochlorite. Industries must follow best practices that include proper dilution, controlled use, and adequate treatment of effluents before discharge to protect ecosystems.

Frequently asked questions (FAQs)

Mechanism of action

Sodium hypochlorite's disinfecting action is based on its ability to oxidize organic materials. When it comes into contact with pathogens such as bacteria and viruses, it disrupts their cellular structures. This oxidative potential is responsible for the effective elimination of microorganisms on surfaces.

In healthcare, sodium hypochlorite plays a vital role in infection control. By regularly disinfecting surfaces and instruments, its application significantly reduces the transmission of infections, protecting both patients and healthcare workers. The efficacy of this chemical in controlling outbreaks of healthcare-associated infections cannot be overstated.

Chemical reactions involving sodium hypochlorite

Sodium hypochlorite participates in numerous chemical reactions, primarily oxidation processes. It is an excellent oxidizing agent, capable of oxidizing various organic compounds, making it valuable in many chemical preparations.

In terms of neutralization, sodium hypochlorite will react with acids to produce chlorine gas, hence the importance of avoiding these combinations. Stability is another consideration; its solutions can degrade over time, especially when exposed to heat or light, underscoring the need for proper storage conditions.

Best practices for use and application

For effective results, it is essential to use sodium hypochlorite at the recommended concentrations for different applications. In household cleaning, a typical dilution ratio is 1:10 for disinfecting surfaces, while laundry applications may require a lower concentration to prevent fabric damage.

To maximize the effectiveness of bleach, proper application techniques are crucial. Allowing sufficient contact time, typically 5 to 10 minutes for disinfecting surfaces, ensures that pathogens are effectively eliminated. Moreover, avoiding common mistakes, such as diluting with hot water or combining with other chemicals, will maintain its integrity and efficacy.

Innovations and future research directions

Ongoing innovations in the chemical industry are focusing on safer alternatives to traditional sodium hypochlorite for disinfection. Research is being conducted into plant-based and less harmful substances that can provide similar antimicrobial efficacy without the associated risks of chemical exposure.

Additionally, novel applications of sodium hypochlorite are being explored in sectors such as agriculture for crop protection and wastewater treatment innovations, continuously expanding its relevance in diverse fields.

Community and collaboration insights

Collaboration among manufacturers, researchers, and regulatory bodies is vital for the ongoing improvement and safe application of sodium hypochlorite. Engaging with users and receiving feedback can lead to refinements in product formulations and safety protocols.

By creating a community around responsible usage, stakeholders can ensure that sodium hypochlorite continues to be a relevant and effective disinfectant while minimizing potential risks and environmental impacts. This cooperative approach can prove beneficial for both users and manufacturers alike.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send bleaching powder sodium hypochlorite to be eSigned by others?

Can I edit bleaching powder sodium hypochlorite on an iOS device?

How do I complete bleaching powder sodium hypochlorite on an Android device?

What is bleaching powder sodium hypochlorite?

Who is required to file bleaching powder sodium hypochlorite?

How to fill out bleaching powder sodium hypochlorite?

What is the purpose of bleaching powder sodium hypochlorite?

What information must be reported on bleaching powder sodium hypochlorite?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.