Ice Machine Maintenance Log Form: A Comprehensive How-To Guide

Understanding the importance of ice machine maintenance

Ice machines are vital components in many commercial and residential settings, providing essential ice supplies for restaurants, hotels, and even home use. Regular maintenance is crucial to ensure these machines operate efficiently and produce clean, safe ice. Neglected machines can suffer from breakdowns, decreased ice quality, and higher energy costs, making it imperative to prioritize regular checks.

Moreover, not maintaining an ice machine can lead to safety hazards, such as contaminated ice and the machine's inefficient operation. By adhering to a structured maintenance schedule noted on an ice machine maintenance log form, users can track service history and ensure compliance with health and safety standards.

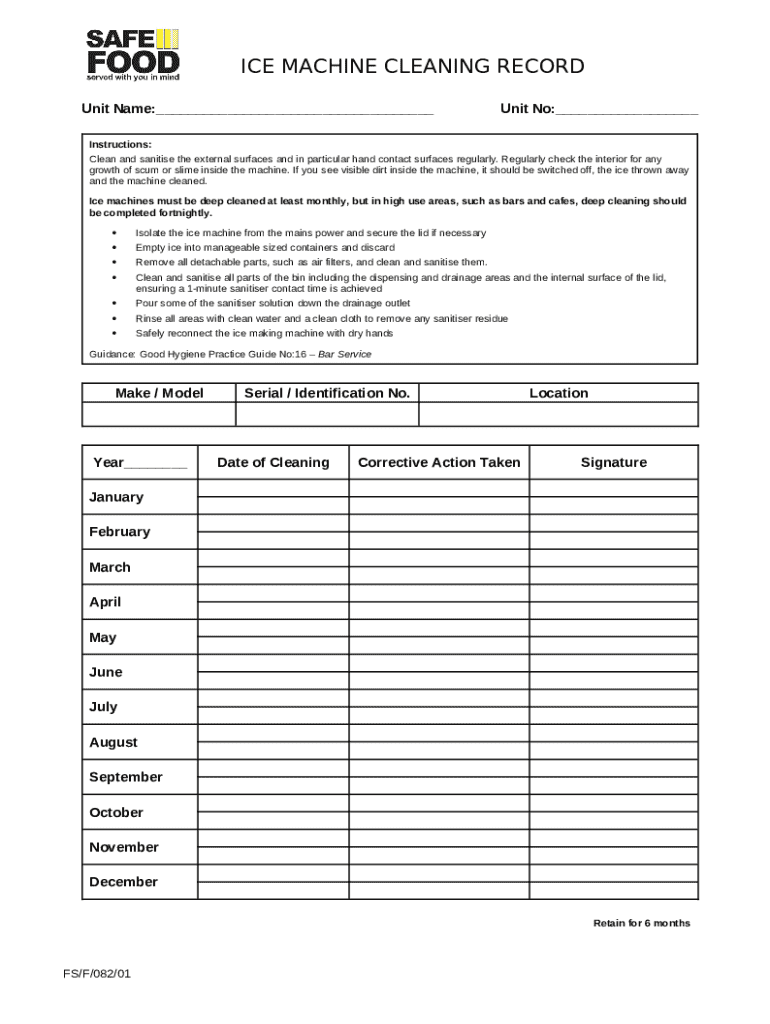

Overview of the ice machine maintenance log form

An ice machine maintenance log form serves as a formal record of all maintenance activities performed on the ice machine. Essential elements of the form typically include:

Date of service – This indicates when the maintenance was performed.

Technician name – The professional who performed the maintenance.

Service details – Describing what maintenance work was done.

Not only does maintaining a detailed log enhance service accountability, but it also simplifies future maintenance inspections by providing a clear history of any anomalies in performance. Such logs cover various types of ice machines, from commercial setups often found in restaurants to residential units prevalent in homes. Keeping track of different brands and models can also help identify patterns in performance specific to each machine.

How to fill out the ice machine maintenance log form

Filling out the ice machine maintenance log form correctly is vital for ensuring comprehensive records. Here's a step-by-step guide on how to do it:

Gathering necessary information – Before starting, ensure you have the machine's model number and previous log details handy.

Documenting service activities – Make sure to include all maintenance tasks performed, such as cleaning the machine, routine inspections, and any repairs carried out.

Capturing technician observations – Encourage technicians to add specific notes about the machine’s performance, potential issues detected, or parts that may require attention soon.

For accuracy, ensure that all entries are immediately recorded post-service. Some common mistakes to avoid include failing to document non-routine repairs or neglecting to update the log after minor maintenance, which can lead to gaps in service records.

Interactive tools for efficient maintenance

Using digital tools for managing ice machine maintenance logs can significantly improve efficiency. Platforms like pdfFiller offer features for online form creation, allowing users to customize their ice machine maintenance log forms easily. Interactive tools can simplify the completion process and can often be accessed from any device, making them highly convenient.

One major benefit of utilizing interactive tools is the ability to collaborate on maintenance logs with team members securely. These tools ensure that everyone's insights and updates are readily available to improve the overall management and maintenance strategy for your ice machines.

Enhancing your maintenance strategy with the ice machine log

To maximize the effectiveness of your ice machine maintenance strategy, consider implementing these best practices:

Scheduling regular maintenance – Create a recurring maintenance calendar to ensure inspections and service occur timely.

Training staff – Equip your team with knowledge about basic maintenance tasks and the significance of documentation.

Leveraging data from logs – Use the information gathered to identify trends in machine performance, helping to anticipate future issues and reduce equipment failure.

Customizing the log form to capture specific details relevant to your operations can also enhance routine oversight. For instance, including fields for supplier information can help trace the origins of failures or inefficiencies more effectively.

Insights on the impact of effective maintenance

Effective maintenance of ice machines not only prolongs equipment life but can also deliver measurable cost savings. Various establishments, especially in the food and beverage industry, have reported increased efficiency and reduced operating costs when they adhered to regular maintenance schedules.

For example, a case study on a chain of restaurants showed that consistently logging maintenance tasks led to a 20% decrease in unexpected breakdowns. Metrics for measuring maintenance effectiveness can include reduced emergency repairs, improved ice quality, and enhanced user satisfaction. Tracking these improvements using the maintenance log reinforces the value of committing to regular service practices.

Industry-specific considerations

Different industries have unique needs when it comes to ice machine maintenance. For instance, in the food and beverage industry, strict health and safety regulations demand high standards of cleanliness and regular checks. Conversely, establishments in the hospitality sector may focus more on the aesthetic appeal and customer satisfaction, requiring quick servicing to maintain reputation.

Diverse usage patterns can also dictate maintenance frequency. High-volume establishments should anticipate more wear and tear and adopt a more proactive maintenance schedule compared to low-volume users. Recognizing these industry-specific requirements and adapting maintenance strategies can yield significant benefits.

Resources to support ice machine maintenance

Accessing comprehensive maintenance checklists through platforms like pdfFiller can enhance your maintenance efforts. These resources often offer specific protocols tailored to various ice machine models and types, ensuring users follow best practices.

In addition to checklists, tutorials and videos can provide insights into using the maintenance log effectively, guiding users through filling out forms and navigating any intricate features. Leverage these free resources for effective equipment management.

Trust and security with pdfFiller

Security is paramount when handling maintenance logs that may contain sensitive information. pdfFiller ensures user privacy and document security, allowing for secure collaborations on maintenance logs with team members. Trust in the document management process can enhance operational efficiency while safeguarding important data.

Future-proofing your ice machine maintenance

As technology continues to evolve, so do the standards and practices surrounding ice machine maintenance. By staying informed on industry trends and emerging technologies, users can prepare for operational changes that may necessitate adjustments in maintenance strategies. This includes adapting to evolving maintenance regulations that could affect the frequency and nature of service needed.

Preparing for fluctuations in operational needs is crucial. Ensuring your maintenance log is adaptable to varying service demands can help safeguard against unexpected equipment failures and enhance longevity.

FAQs about ice machine maintenance

Common queries about filling out the ice machine maintenance log form often revolve around recording specific incidents or maintaining accuracy. Some users may question how to document unique repairs or service anomalies effectively. It’s important to promote open lines of communication among technicians and supervisors regarding what information should be documented in the logs.

For troubleshooting issues with ice machines, maintenance logs can serve as valuable reference points to identify recurring problems and enhance operational efficiency. Regularly reviewing past logs can help pinpoint areas for improvement in both maintenance practices and machine performance.

Maximizing the use of maintenance logs

Access to digital maintenance logs becomes increasingly crucial for effective equipment management. With platforms like pdfFiller, users can easily retrieve maintenance logs from anywhere, thus streamlining the documentation process.

Integrations with other management systems can enhance the functionality of the ice machine maintenance log. Cloud-based document solutions ensure that all stakeholders have up-to-date information, encouraging collaborative efforts in maintaining optimal ice machine performance.