Stored materials schedule and form: A comprehensive guide

Understanding stored materials: An overview

Stored materials refer to items that have been purchased and delivered for a construction project but are not yet installed. These materials may include anything from concrete and steel to fixtures and appliances. The concept is fundamental in construction and contracting, where cash flow management and materials tracking play pivotal roles in the timely and budget-conscious execution of projects.

One vital element of managing these stored materials is the stored materials schedule. This schedule is crucial for both contractors and project owners as it helps track material ownership, ensures proper payment for work performed, and facilitates inventory management. By maintaining a transparent and accurate schedule, all stakeholders can significantly reduce the risk of payment disputes and misunderstandings.

Improved cash flow management: Properly accounting for stored materials can minimize delays in project funding.

Reduced risk of disputes: Clearly document ownership to avoid conflicts over material use and payment responsibilities.

Better inventory control: Track materials to know what’s on-site and ready for installation.

The role of a stored materials schedule

A stored materials schedule is essentially a detailed list that outlines what materials are stored offsite, how much has been purchased, and their current location. This document serves a dual purpose: firstly, it acts as an inventory tracker, and secondly, it informs the payment process. Having a clear schedule allows contractors to request payments based on the value of materials that have been delivered but not yet installed.

Maintaining this schedule brings numerous advantages. It enables proactive payment management and ensures that cash flow remains consistent as the project progresses. By keeping a well-documented schedule, project managers can easily determine how much has already been paid for materials, which helps prevent overpayments and improves overall financial management.

Enables transparency in payments: Clearly shows which materials are paid for and which are pending.

Facilitates refunds or claims: Helps in asserting ownership in case of disputes.

Optimizes resource allocation: Ensure materials are readily available when needed.

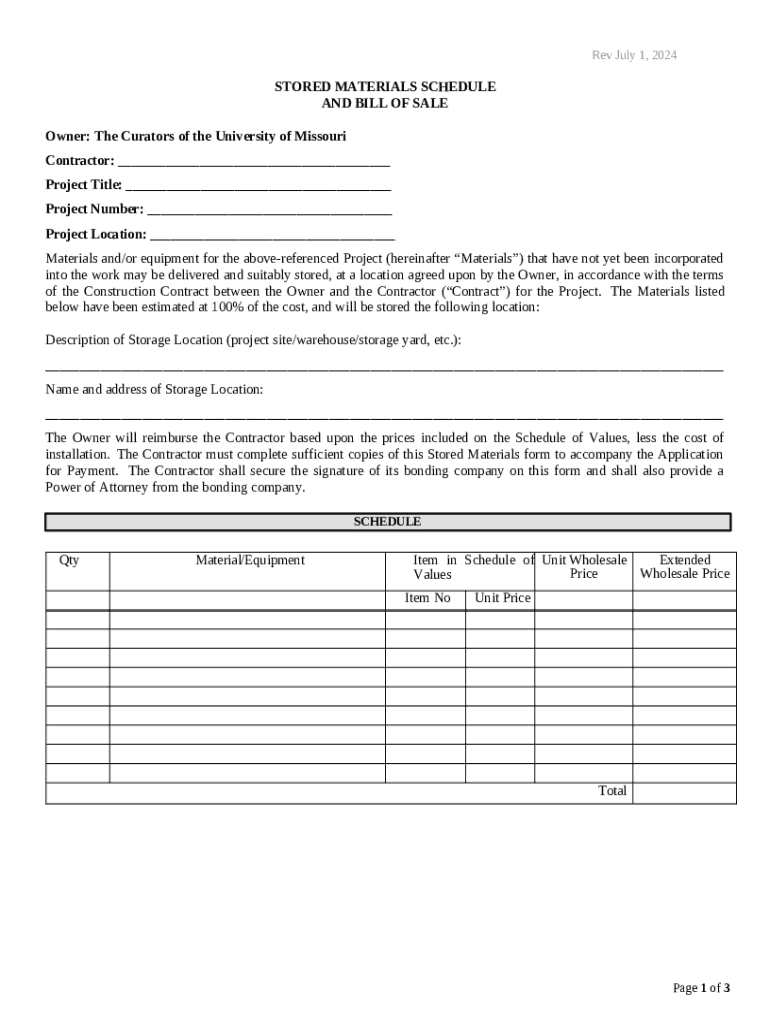

Essential components of a stored materials schedule

Creating a thorough stored materials schedule involves documenting several key components. These components serve to ensure that all information is accurately captured and easily accessible, contributing to efficient project execution.

The following items should be included in every stored materials schedule:

A detailed list of materials: Every item should be specified, including quantity and type.

Detailed specifications: Include manufacturer information, materials grade, and any compliance standards.

Location of storage: Specify where each material is stored to ensure proper handling.

Ownership documentation: Outline who owns the materials, including instructions for lien rights.

Introduction to the stored materials form

The stored materials form is a critical document that complements the stored materials schedule. This form summarizes essential information about the stored materials and is usually submitted during payment requests to help expedite the process.

Key information typically found on the stored materials form includes the following:

Project details: Including project name, location, and contract number.

Contractor and subcontractor details: Names and contact information for all parties involved.

Itemized list of stored materials: Details such as description, quantity, location, and costs.

Step-by-step guide to completing the stored materials form

Completing the stored materials form accurately is imperative for ensuring a smooth payment process. Here’s a detailed guide on how to go about it:

Gather necessary project information to ensure accuracy. This includes dates, installation timelines, and contract numbers.

Compile a comprehensive list of stored materials ensuring every material is accounted for with correct specifications.

Fill out the form accurately. Double-check all entries for consistency with the stored materials schedule.

Obtain all necessary signatures from parties involved. This may include contractors, project managers, and financial officers.

Submit the form for review and approval by relevant stakeholders, ensuring that feedback is documented.

Tips for effective management of stored materials

Managing stored materials can be challenging without the right strategies. Adhering to certain best practices can significantly improve tracking and documentation accuracy.

Consider these tips to enhance your management process:

Regularly update your stored materials schedule to reflect current inventory and ensure it aligns with the stored materials form.

Utilize pdfFiller’s tools to streamline document management, leveraging its editing capabilities for easy updates.

Make use of the eSign features for quicker approvals from stakeholders, minimizing delays.

Ensure collaboration options are set up for team members to access and edit documents, enhancing communication.

Implement safeguards to prevent disputes, such as maintaining thorough records and communication about material usage.

Common issues and troubleshooting

Even with the best of intentions, common issues can arise when dealing with a stored materials schedule. Recognizing these challenges upfront can ease your management efforts.

Some frequently encountered problems include discrepancies in billing, miscommunication about material ownership, and delays in payments. Here are a few solutions to address these issues:

Maintain open communication among the project team to quickly resolve misunderstandings regarding material use or payments.

Regularly reconcile schedules and forms to ensure all information aligns.

Document everything meticulously to create a clear trail for all purchases and material use.

Be proactive in resolving billing issues by addressing discrepancies immediately with clear documentation.

Compliance and best practices

In the construction industry, compliance is paramount. Regulatory requirements often inform how stored materials are documented and managed. Familiarity with local laws, particularly lien laws, is necessary for preventing legal complications.

A compliance checklist can serve as an effective tool to ensure all regulatory obligations are met. Key components of effective compliance include:

Regularly review relevant legislation pertaining to construction and storage materials.

Understand specific lien laws to assert rights over stored materials effectively.

Incorporate compliance checks into regular project reviews to ensure adherence to both project and regulatory standards.

Leveraging technology for document management

Technology has revolutionized how construction documents are managed, and implementing digital solutions can significantly enhance efficiency. Using platforms like pdfFiller allows teams to seamlessly create, edit, and manage documents regarding stored materials.

The advantages of using pdfFiller for your stored materials schedules and forms include:

User-friendly editing features that make it easy to update documents in real-time.

Cloud-based storage enabling easy access from anywhere, keeping teams connected.

Interactive tools that enhance project tracking and documentation efforts.

Conclusion: Streamlining your stored materials process

Managing a stored materials schedule and form efficiently can substantially improve a construction project's financial management and operational success. By understanding the importance of documentation and adopting best practices, teams can minimize risks and enhance communication.

Whether preparing a materials schedule or leveraging technology like pdfFiller for document management, being proactive can lead to smoother project execution and reduced disputes. Stay organized, communicate clearly, and utilize available tools to succeed in your construction endeavors.