Get the free cook/chill horizontal agitator stationary mixer kettles

Get, Create, Make and Sign cookchill horizontal agitator stationary

Editing cookchill horizontal agitator stationary online

Uncompromising security for your PDF editing and eSignature needs

How to fill out cookchill horizontal agitator stationary

How to fill out cookchill horizontal agitator stationary

Who needs cookchill horizontal agitator stationary?

Cookchill Horizontal Agitator Stationary Form: Streamlining Food Processing

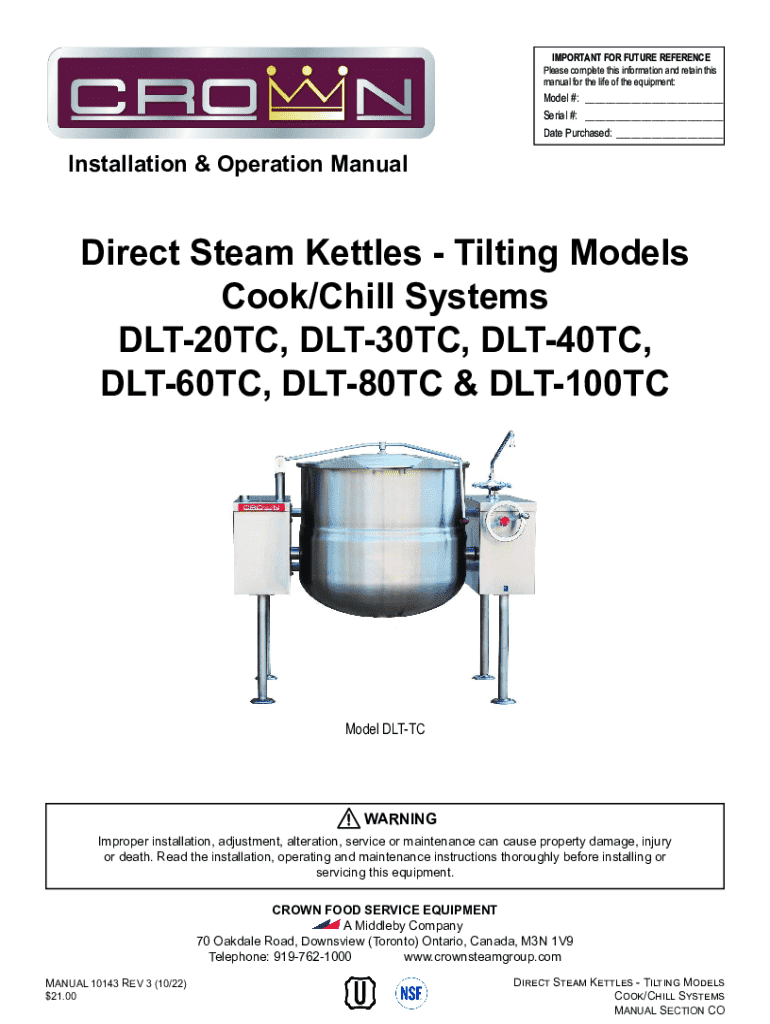

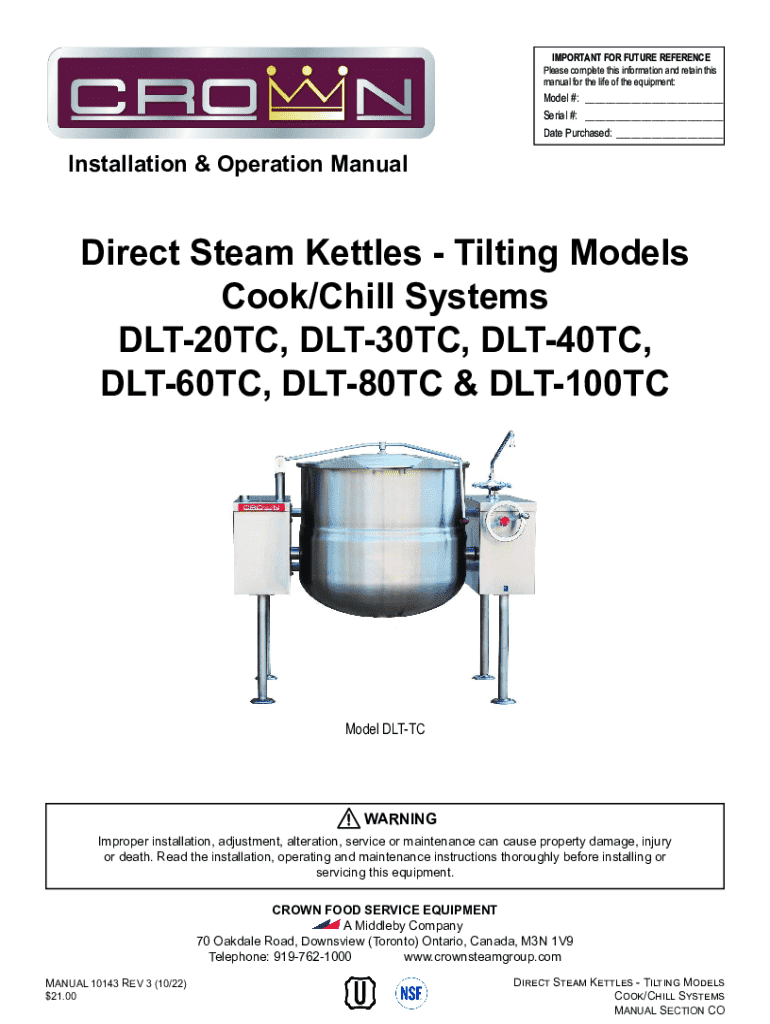

Overview of cookchill horizontal agitator stationary form

The cookchill horizontal agitator stationary form is a critical component in modern food processing, particularly suited for prepared meal systems. This method involves cooking food to a suitable temperature, then rapidly chilling it to preserve quality and safety. The stationary agitator ensures even mixing and consistent results, which are paramount in large-scale food production.

Utilizing a cookchill system allows kitchens, especially in establishments like hospitals and catering services, to produce high-quality meals while maintaining food safety. The importance of this system in food production cannot be overstated, as it enhances efficiency, reduces food wastage, and maintains nutritional value.

Types of cookchill horizontal agitators

Cookchill horizontal agitators come in various forms, categorized primarily by their orientation and mobility. Horizontal agitators are preferred in many industrial settings due to their ability to handle larger volumes and provide a more uniform mixing compared to vertical variants.

While stationary models are ideal for fixed installations where space is not limited, mobile options offer flexibility for various cooking scenarios. The choice between stationary and mobile depends on operational needs and spatial constraints.

Components of a cookchill horizontal agitator stationary form

Understanding the components of the cookchill horizontal agitator is crucial for effective operation. Key parts include specialized agitator blades designed for both mixing and aeration, which contribute to evenly cooked and chilled food.

These systems typically feature integrated heating and cooling systems that regulate temperatures, as well as control panels equipped with user-friendly interfaces. Attention to the materials used is also essential; stainless steel is a common choice due to its food-safe properties and resistance to corrosion.

How to use a cookchill horizontal agitator stationary form

Operating a cookchill horizontal agitator requires a systematic approach to ensure optimal results. Here’s a step-by-step guide to effectively use this essential equipment.

FAQs during use often cover issues like ideal ingredient ratios or the correct temperature settings. Users might also face common problems, for which troubleshooting guides should be easily accessible.

Best practices for efficiency and safety

To maximize the benefits of a cookchill horizontal agitator, adhering to safety protocols is paramount. This includes ensuring machine maintenance is performed regularly and observing hygiene standards to avoid contamination.

Additionally, understanding energy efficiency strategies can lead to cost savings. Efficient wiring and insulation of heating and cooling systems prevent energy loss and reduce operational costs.

Comparisons with other cooking systems

A comparative analysis suggests that the cookchill method, particularly utilizing horizontal agitators, has distinct advantages over traditional cooking methods. Traditional cooking can often lead to uneven heating and longer preparation times, while cookchill systems allow for batch processing, ensuring consistent quality.

Furthermore, the operational costs associated with cookchill technology can be offset by reduced food waste and extended shelf life of prepared meals, leading to improved return on investment (ROI).

Interactive tools and features

Modern cookchill systems come equipped with various interactive tools that enhance usability. Digital formats allow users to easily access and edit recipes or operational logs. Enhancements such as e-signing capabilities streamline documentation, which is particularly useful for compliance in food production.

Collaborative features enable team members to contribute to documentation remotely, fostering efficient communication. Utilizing cloud-based document management aids in the smooth running of kitchen operations.

Customer testimonies and case studies

Feedback from users of cookchill systems frequently highlights the overwhelming improvement in food quality and production efficiency. For instance, a large catering service noted a significant reduction in food spoilage rates after implementing a cookchill process.

Case studies from hospitals have shown enhanced patient satisfaction due to improved meal presentation and safety standards. Such testimonials contribute to the increasing adoption of cookchill technologies across various sectors.

Support and service options

Comprehensive support services are vital for the successful operation of cookchill horizontal agitators. Access to live support features ensures that users can quickly resolve any operational issues that arise during use.

Furthermore, maintenance scheduling services help ensure that the systems undergo regular check-ups, preventing unforeseen breakdowns. Understanding warranty options also contributes to more secure investments in cooking technology.

Future trends in cookchill technology

As technology evolves, innovations in horizontal and vertical cooking systems are anticipated. The integration of IoT in cookchill processes could lead to even smarter kitchen environments where machines communicate preferences and suggest optimal settings.

Additionally, advancements in food safety measures and quality control will likely result in even better products, further elevating the standards within the food industry.

Related products and systems

To complement cookchill horizontal agitators, various related products enhance operational efficiency. Batch chillers, for example, are critical for quickly lowering food temperatures post-cooking to ensure safety.

Food pumps and mixer kettles are additional systems that can integrate seamlessly with cookchill operations, allowing for a smooth workflow. Comparing these products with existing systems can help businesses make informed decisions.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my cookchill horizontal agitator stationary directly from Gmail?

How can I send cookchill horizontal agitator stationary to be eSigned by others?

How do I edit cookchill horizontal agitator stationary in Chrome?

What is cookchill horizontal agitator stationary?

Who is required to file cookchill horizontal agitator stationary?

How to fill out cookchill horizontal agitator stationary?

What is the purpose of cookchill horizontal agitator stationary?

What information must be reported on cookchill horizontal agitator stationary?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.