Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Comprehensive Guide to Material Safety Data Sheet Form

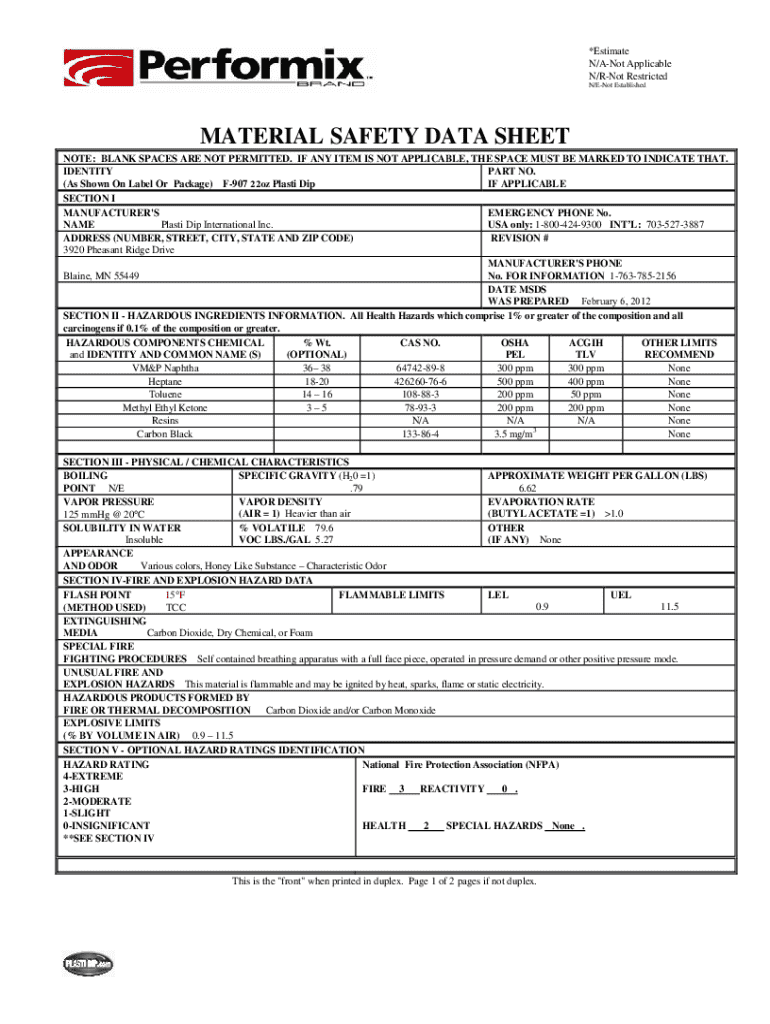

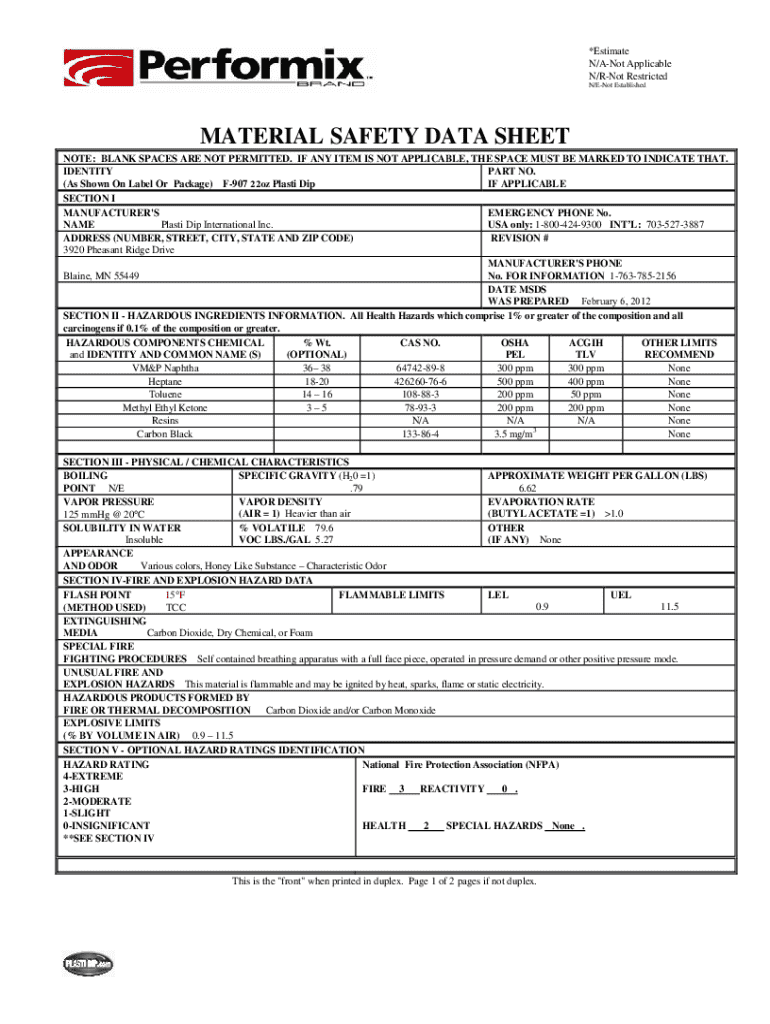

Overview of material safety data sheets (MSDS)

Material Safety Data Sheets (MSDS), now more commonly referred to as Safety Data Sheets (SDS), are essential components of workplace safety and hazardous materials communication. These documents serve as detailed informational resources regarding the properties of a specific chemical or substance, outlining handling procedures, dangers, and emergency measures. The MSDS is aimed at providing crucial information to safely manage and work with hazardous materials, thereby reducing accidents and workplace hazards.

The importance of MSDS extends beyond individual safety; they ensure compliance with various regulatory frameworks, notably the Occupational Safety and Health Administration (OSHA) regulations. Under OSHA’s Hazard Communication Standard (HCS), employers are required to maintain MSDS for hazardous substances within the workplace to inform employees about risks associated with their use.

Structure of a material safety data sheet

An MSDS is standardized into sections that provide comprehensive details on the chemical being documented. Here’s a breakdown of each section:

Detailed breakdown of MSDS sections

A thorough understanding of each section is crucial for anyone involved in handling hazardous materials. The following subsections detail the essential components of the MSDS:

In Section 4, First Aid Measures, the document will outline specific actions to take in case of exposure—whether it be inhalation, eye contact, or skin contact. Quick and effective responses can significantly reduce the severity of injury. Section 5, Fire-Fighting Measures, delves into recommended firefighting procedures, highlighting suitable extinguishing media, and necessary precautions against potential fire hazards.

Section 6 details Accidental Release Measures, presenting emergency procedures in case of spills or leaks, emphasizing the importance of immediate action to prevent environmental contamination. Moreover, in Section 7, Handling and Storage, the MSDS outlines guidelines to ensure safe use and storage conditions, including temperature and moisture levels.

Moving on to Section 8, this segment covers Exposure Controls and Personal Protection. It delineates occupational exposure limits where applicable, and advises on personal protective equipment (PPE) to mitigate risks. Physical properties such as boiling point, flash point, and solubility are commonly detailed in Section 9, providing critical data relevant for risk assessment.

Stability and Reactivity information can be found in Section 10, describing potentially hazardous reactions and safe handling conditions. Following that, Section 11 addresses Toxicological Information, including symptoms, long-term effects, and toxicological data, essential for healthcare providers in case of exposure. The environmental aspects are covered in Section 12, where ecological implications of the substance are addressed.

Section 13 concerns Disposal Considerations, providing waste disposal recommendations, which is crucial for regulatory compliance. Transport information in Section 14 classifies hazards related to transport, ensuring safety during shipping. Lastly, Section 15 deals with Regulatory Information, summarizing compliance with local, national, and international guidelines, while Section 16 concludes with miscellaneous information and disclaimers that hold relevance to the MSDS.

Practical steps for preparing a material safety data sheet

Creating an effective Material Safety Data Sheet requires a methodical approach. Follow these steps to fill out each section accurately:

Common pitfalls include overgeneralizing information or neglecting to update the MSDS after changes in product formulation or regulatory revisions. Utilizing templates can streamline the creation process significantly. For instance, pdfFiller provides customizable MSDS templates that can be easily edited and filled in as needed, ensuring you meet compliance standards.

Incorporating technology can help enhance the accuracy and clarity of your MSDS. Tools such as pdfFiller’s editing functions enable seamless document updates and collaboration amongst teams. By prioritizing accuracy and transparency, you foster a safer work environment.

Interactivity and collaboration

Leveraging interactive platforms enhances collaboration on MSDS projects, especially when working within teams. pdfFiller provides robust features for collaborative editing, allowing multiple users to contribute in real-time. This not only fosters communication but also ensures that various insights can be incorporated, leading to a more thorough and well-rounded MSDS.

Version management is critical in maintaining the integrity of documents. With pdfFiller, teams can effectively share and manage different versions of MSDS documents. By tracking changes and holding discussions around edits, teams can assure compliance and ensure every team member is informed of the most current data.

Additionally, electronic signatures add a layer of verification that ensures compliance is maintained. By employing eSigning solutions, teams can demonstrate that they have reviewed and approved the critical safety information, creating a transparent and accountable process.

Automating the MSDS creation process

The automation of the MSDS creation process is a game changer for many organizations. Automation tools remove the burden of repetitive tasks associated with document management, enabling teams to focus on compliance and safety protocols instead.

Form integration through APIs significantly enhances the workflow associated with MSDS documentation. This allows businesses to create automated templates that automatically populate based on incoming data. For instance, when a new chemical is introduced, the system can generate a preliminary MSDS draft based on the pre-set templates that reflect necessary compliance details mandated by OSHA.

Furthermore, streamlining document management minimizes errors and reduces time spent on MSDS updates, ensuring that every document is ready for immediate review. By automating routine tasks within MSDS preparation, organizations position themselves as leaders in safety and compliance.

Use cases and applications

Material Safety Data Sheets are indispensable in various industries, especially those that involve the handling of hazardous substances. Here are some use cases where MSDS preparation is essential:

Special considerations must be made for particularly hazardous materials, like toxic substances or those that may react violently under certain conditions. Thus, having accurate MSDS not only complies with legal requirements but protects employees and the environment.

Compliance and best practices

To maintain workplace safety and comply with regulatory frameworks, it is crucial to keep MSDS updated. Review requirements are often dictated by the nature of the chemicals used and can vary from quarterly to annually. An employer should proactively communicate any changes in chemical composition or safety protocols to staff.

Additionally, providing training for employees on the importance and proper use of MSDS enhances safety awareness. Employees should be familiar with how to read and interpret these documents effectively, ensuring they can act swiftly in emergencies. Adhering to the Globally Harmonized System (GHS) standards ensures that MSDS are consistent and understandable across international borders.

Establishing these best practices cultivates a culture of safety and responsibility, enhancing organizational efficiency and reducing the risk of workplace accidents.

Additional resources for MSDS management

Within the dynamic landscape of safety management, various resources can support teams in MSDS management. pdfFiller offers templates specifically designed for creating MSDS, along with industry-specific examples crucial for tailoring documents to particular needs.

Community forums provide an excellent platform for professionals to share experiences, challenges, and best practices. Engaging in these discussions can lead to innovative solutions and enrich understanding of systemic improvements in MSDS compliance and management.

Tools and features of pdfFiller to manage MSDS

pdfFiller stands out as a robust platform for managing documents, including MSDS. Its document editing capabilities allow users to easily fill out forms, edit existing entries, and update information as needed swiftly. These features enhance the efficiency and accuracy of MSDS creation.

The platform also includes sign and share features that facilitate compliance verification. By streamlining these processes, organizations can ensure that all necessary stakeholders have access to the latest versions of important safety documents. Additionally, tracking changes and maintaining document history allows businesses to document revisions systematically, ensuring compliance with regulatory demands.

Expert insights and trending topics in MSDS

Staying updated on recent developments in regulatory requirements pertaining to MSDS is imperative for professionals in all industries that handle hazardous substances. Regulatory bodies like OSHA continuously update guidelines to enhance safety protocols, making it essential for companies to adapt.

Innovations in document management technology, such as automation and cloud-based solutions, are also transforming how organizations create and manage MSDS. Future trends appear to lean toward more integrated systems that harmonize compliance, documentation, and training into a cohesive platform to guard against workplace hazards effectively.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find material safety data sheet?

How do I execute material safety data sheet online?

Can I edit material safety data sheet on an iOS device?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.