Get the free Non-polluting Composites Repair and Remanufacturing for Military Applications: Induc...

Get, Create, Make and Sign non-polluting composites repair and

How to edit non-polluting composites repair and online

Uncompromising security for your PDF editing and eSignature needs

How to fill out non-polluting composites repair and

How to fill out non-polluting composites repair and

Who needs non-polluting composites repair and?

Non-polluting composites repair and form

Understanding non-polluting composites

Non-polluting composites are advanced materials designed to minimize environmental impact while maintaining high performance. Typically made from renewable resources or recyclable materials, these composites exhibit characteristics such as light weight, durability, and resistance to extreme conditions. Their importance in promoting sustainability within various industries cannot be overstated, especially given the growing concerns about climate change and the need for eco-friendly practices.

Compared to traditional composites that often rely on petroleum-based products and toxic resins, non-polluting composites provide a cleaner alternative that aligns with global sustainability goals. This shift in material manufacturing and usage reflects a broader trend toward environmentally responsible practices across various sectors.

Applications of non-polluting composites

The applications of non-polluting composites span multiple industries, showcasing their versatility and effectiveness. In aerospace and military sectors, these materials are utilized for crafting lightweight components that enhance fuel efficiency and reduce emissions. Innovations in the automotive sector further emphasize this trend, with manufacturers adopting non-polluting composites in vehicle interiors and body panels to decrease overall vehicle weight.

Furthermore, in construction and infrastructure development, non-polluting composites have revolutionized the way materials are selected for building projects. Their resistance to corrosion and degradation contributes to longer lasting structures while minimizing environmental footprints. Emerging markets, such as renewable energy and bio-based product development, are expected to further expand the reach of non-polluting composites, indicating strong future trends.

Repairing non-polluting composites

Repairing non-polluting composites involves several critical steps to ensure integrity and longevity. The first step is assessing damage through visual inspection and non-destructive testing methods such as ultrasonic or infrared testing, which allow detailed evaluations without compromising material quality. Proper assessment is essential for determining the type of repair needed.

Once the damage has been assessed, several repair techniques may be employed. Adhesive bonding stands out as a common method, utilizing eco-friendly adhesives that create strong, lasting bonds. Patch repairs involve applying a new composite layer over the damaged area, which can be done using similar non-polluting materials for better compatibility. Heat treatment methods may also be applied, especially to restore thermoset composites to their initial strength.

The step-by-step repair process should include the following steps: preparing the surface by cleaning and possibly sanding to improve bond strength, selecting appropriate repair materials that align with the sustainability criteria, applying the repair techniques precisely, and finally testing the repair integrity through stress testing methods to ensure the composite retains its functional properties.

Innovations in non-polluting repair materials

Selecting non-polluting repair materials requires careful consideration of environmental impact, performance, and compatibility with existing composites. Eco-friendly repair materials may include bio-based epoxies, sustainable fibers, and non-toxic adhesives that not only repair but also further the sustainability narrative. Leading brands in the market have begun to innovate in this area, offering products that meet stringent environmental standards while ensuring high performance.

Notable case studies illustrate successful repair initiatives using non-polluting materials. For instance, certain aerospace companies have effectively used eco-friendly adhesives to repair composite wings, maintaining both structural integrity and environmental standards. This trend reflects a growing willingness within the industry to adopt greener practices, demonstrating how innovations in repair materials can lead to successful outcomes in practical applications.

Documenting repair processes: The role of templates in management

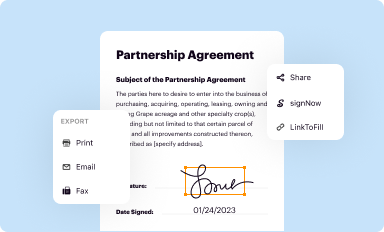

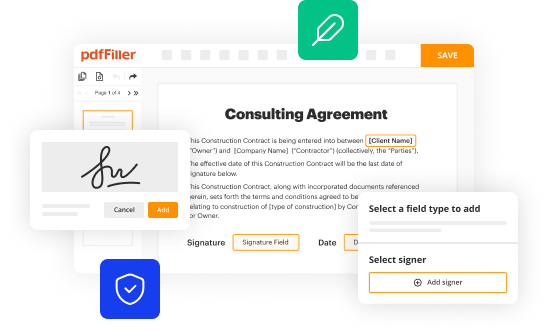

Accurate documentation is crucial in composite repair, especially for non-polluting materials. Detailed records of the repair process enhance accountability, traceability, and future maintenance activities. pdfFiller simplifies document creation through template customization, allowing professionals to create forms tailored to specific repair processes, which ensures consistency and accuracy across projects.

The benefits of eSigning and collaboration in repair documentation are numerous. It streamlines approvals and communication among team members, enhancing efficiency and reducing the likelihood of errors. When preparing and managing repair forms, suggested fields for comprehensive reporting should include repair material specifications, damage assessment details, and bit notes on testing results. Ensuring accuracy and compliance within these documents fosters trust and enhances project outcomes.

Challenges in non-polluting composite repair

Despite the many advantages of non-polluting composites, several challenges still hinder their repair. One common challenge is the accessibility of specialized materials and adhesives, which may not be as widely available as traditional options. Additionally, some repair techniques require advanced skills and training, necessitating investment in professional development and knowledge-sharing within the industry.

Environmental regulations are also increasingly impacting composite repairs. Manufacturers must keep abreast of changing laws regarding material usage and disposal, which can complicate repair strategies. However, as innovations emerge, the future landscape of non-polluting composites looks promising, with technological advancements likely to address current limitations and improve overall repair processes.

Leveraging technology for composite repair efficiency

Technology plays a pivotal role in enhancing the efficiency of composite repair processes. Interactive tools and online resources provide training opportunities for professionals looking to develop their skills in working with non-polluting composites. Online communities for composite repair professionals facilitate knowledge sharing, where best practices and repair techniques are discussed and refined.

Furthermore, integrating cloud-based solutions for document management, such as pdfFiller, offers enhanced accessibility and collaboration. This technology enables teams to work on repair documentation from anywhere, allowing for seamless updates, approvals, and communication, thus greatly speeding up repair activities without sacrificing accuracy.

Enhancing collaboration in composite repair projects

Effective team coordination enhances the success rate of composite repair projects. Techniques for improving collaboration include defining clear roles within repair teams and utilizing collaborative platforms that facilitate real-time communication. This approach not only strengthens teamwork but also minimizes misunderstandings and errors during repairs.

Case studies demonstrate how successful collaborative repair assignments lead to better project outcomes. For example, aviation repair teams leveraging cloud tools experienced increased efficiency, significantly reducing turnaround time on repairs. The impact of real-time collaboration tools on repair efficiency is evident in how teams can engage with documents, share insights, and provide updates instantaneously, ensuring they proceed with well-rounded information.

Final considerations for sustainable composite practices

Adopting best practices for sustainable repair and maintenance of non-polluting composites is essential for reducing environmental impact. Regular training sessions centered on eco-friendly practices enhance knowledge within teams and promote compliance with emerging standards. Encouraging industry-wide adoption of non-polluting materials through collaborative efforts can significantly shift traditional practices toward more sustainable outcomes.

The role of educational resources in promoting sustainable practices cannot be minimized. Ongoing research, workshops, and seminars can empower individuals and teams to stay updated and understand the full potential of non-polluting composites. By fostering a culture of sustainability, industries can work together toward shared environmental goals, driving innovation and responsibility in composite repair.

Summary of pdfFiller's benefits

pdfFiller provides a comprehensive document management solution specifically tailored for the composite industry. By enabling streamlined document management, from creation to eSigning, pdfFiller empowers teams to collaborate efficiently and keep pace with the demands of composite repair projects. The platform's value lies in its cloud-based design, allowing users to access repair documentation from anywhere, facilitating real-time adjustments and updates.

In summary, pdfFiller enhances the efficiency and accuracy of document creation, ensuring that professionals engaged in non-polluting composites repair have the tools they need to succeed. This capacity for comprehensive document management greatly contributes to fostering sustainable practices across the industry, aligning with the necessary transition toward eco-friendly solutions.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send non-polluting composites repair and to be eSigned by others?

How do I execute non-polluting composites repair and online?

How can I edit non-polluting composites repair and on a smartphone?

What is non-polluting composites repair?

Who is required to file non-polluting composites repair?

How to fill out non-polluting composites repair?

What is the purpose of non-polluting composites repair?

What information must be reported on non-polluting composites repair?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.