Get the free Crane Operator Daily Inspection Checklist

Get, Create, Make and Sign crane operator daily inspection

Editing crane operator daily inspection online

Uncompromising security for your PDF editing and eSignature needs

How to fill out crane operator daily inspection

How to fill out crane operator daily inspection

Who needs crane operator daily inspection?

Crane Operator Daily Inspection Form: Your Essential Guide

Understanding the crane operator daily inspection form

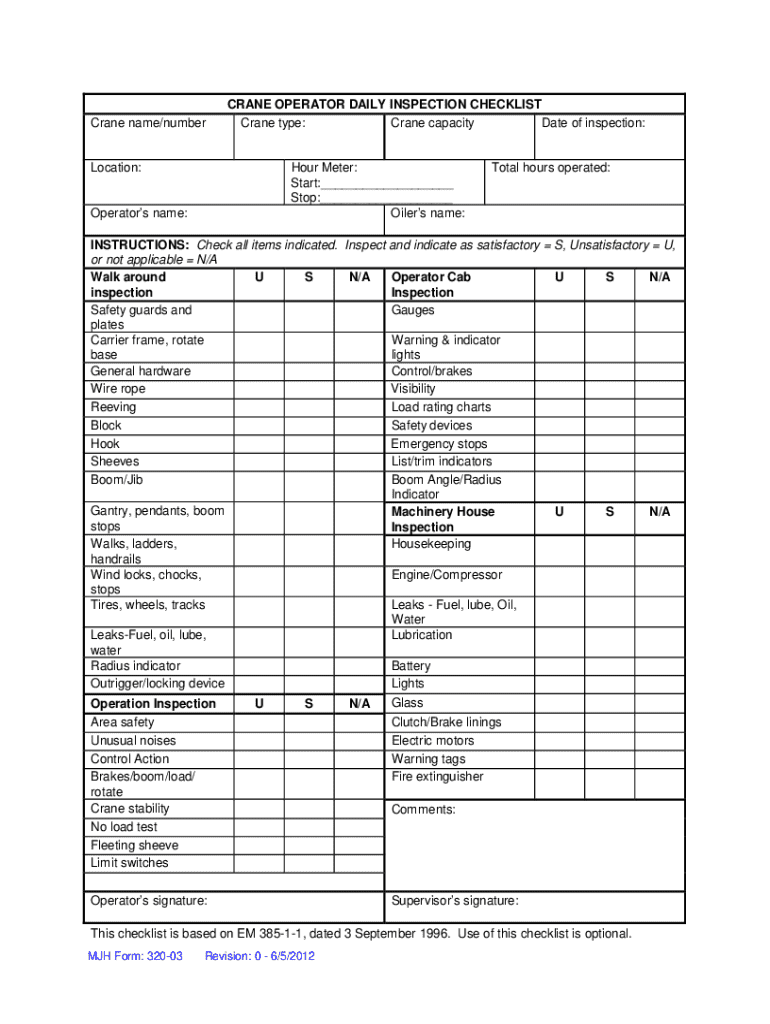

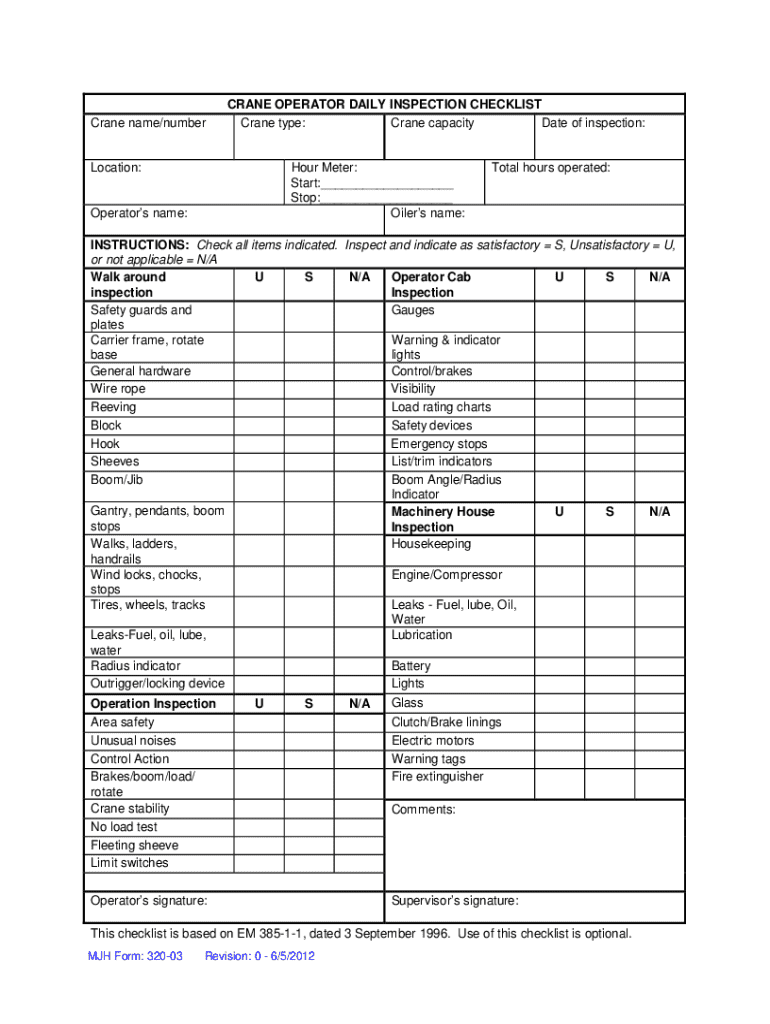

Crane operations demand meticulous attention to detail, primarily captured through the crane operator daily inspection form. This document serves as a foundational tool, ensuring that operators conduct systematic checks of the crane’s condition before every shift. The emphasis on daily inspections cannot be overstated, as they prevent accidents, ensure compliance with safety regulations, and enable operators to address any potential issues before they escalate.

From a regulatory perspective, inspections are mandated by various occupational safety standards, which require that cranes are meticulously inspected for functionality and safety. Complying with these requirements not only enhances workplace safety but also protects organizations from potential liabilities. The inspection form encapsulates vital components that evaluate the functionality and safety of the equipment.

Essential elements of the crane operator daily inspection form

The crane operator daily inspection form is structured to collect comprehensive data, vital for effective inspections. Each element of the form aids operators in documenting the status of the equipment accurately, which is crucial for safety management and operational integrity.

Identification information is paramount, requiring details such as the crane's make, model, and serial number. It also captures the operator's name and certification details, ensuring that personnel conducting the inspection are qualified and capable. This accountability fosters a safety-centered environment.

Comprehensive inspection checklist

A thorough inspection checklist is essential for identifying potential problems that could compromise safety. Operators should start with structural integrity checks, examining the frame and boom condition for any signs of wear or damage. Hydraulic systems, including hoses, should also be checked for leaks or abrasions.

Beyond structural assessments, operators must evaluate mechanical and safety features such as load indicators, alarms, brakes, and stabilizers. These elements are pivotal for safe lifting and preventing load failure.

Common findings and issues to report

Identifying and reporting defects is crucial for maintaining equipment safety and efficiency. Operators should be trained to recognize signs of wear, such as rust, fraying cables, or leaks. When discrepancies are noted, they should be documented thoroughly on the inspection form.

Timely reporting is not just best practice; it's an imperative aspect of crane safety. Delays in addressing detected problems could result in severe accidents or equipment failures, making it essential for operators to take immediate action when issues arise.

Filling out the crane operator daily inspection form

Properly filling out the crane operator daily inspection form requires attention to detail and a systematic approach. Start by completing each section clearly, ensuring that all necessary information is provided without leaving blanks. This is vital for maintaining accurate records that reflect the crane's operational status.

Operators should include descriptive comments about any anomalies encountered during the inspection. Suggestions for clear commentary include being specific about issues and their locations, taking photographs for visual documentation, and maintaining timestamps for evidence.

Leveraging technology for crane inspections

Technology plays a transformative role in enhancing the inspection process for cranes. Digital tools simplify documentation, making the crane operator daily inspection form accessible and editable from anywhere. Solutions like pdfFiller provide functionalities that streamline the creation and management of these forms.

Using a cloud-based solution offers significant advantages, including real-time collaboration with team members, seamless eSigning, and efficient document management capabilities. This technology ensures that all stakeholders have access to the most current inspection records, facilitating better communication and enhanced decision-making.

Safety protocols and best practices for crane operators

The safety of crane operations hinges on rigorous adherence to established safety protocols. Operators should be well-versed in safety regulations, such as those provided by OSHA or local governing bodies, ensuring that their practices align with mandated standards. Regular training and certification are essential for operators to stay updated on best practices and emerging safety technologies.

Promoting a safety-first culture within the workplace is equally important. This involves encouraging open communication regarding safety concerns, conducting refresher training sessions, and fostering an environment where reporting issues is seen as a responsibility rather than a hindrance.

Case studies and real-life examples

Several notable incidents have underscored the need for diligent inspections. Lack of routine checks has led to catastrophic failures, resulting in property damage, injuries, and even fatalities. Studying these unfortunate events reveals a clear pattern: inadequate or ignored inspections often precede serious incidents.

Conversely, companies that implemented strict daily inspection protocols have seen a marked improvement in safety records. These success stories provide valuable lessons, emphasizing the importance of adherence to inspection schedules and thorough documentation of findings.

Frequently asked questions (FAQs)

Many crane operators have queries regarding daily inspections. Common questions revolve around the frequency of inspections, the handling of discovered deficiencies, and the best practices for documenting findings. Clarifying misconceptions about the inspection process is crucial, ensuring operators maintain an understanding of their role and responsibilities.

Resources for further information abound, from regulatory bodies to industry publications. Engaging with these resources can enhance knowledge and foster a culture of continuous improvement among crane operators.

Engaging with the community

Connecting with others in the crane operation industry provides immense benefits. Attending classes and obtaining certifications can enhance skills and knowledge on best practices in crane inspections. Additionally, staying informed about innovations within the sector can significantly contribute to operational efficiency.

Sharing insights and experiences with other operators not only fosters a sense of community but also creates a valuable resource network. Engaging in discussions on challenges and solutions can lead to improved operational practices.

Interactive tools and resources

Users interested in streamlining their inspection processes can take advantage of downloadable templates and checklists specifically designed for daily crane inspections. These tools can significantly enhance efficiency, ensuring no aspect of the inspection is overlooked.

Accessing archived inspection forms allows for a historical review of crane performance, enabling operators to learn from past inspections. Online forums and discussion groups further offer platforms where operators can engage with peers, share experiences, and seek advice.

Recent updates and innovations in crane safety

The landscape of crane safety is continually evolving due to regulatory updates and technological advancements. Recent regulatory changes have reinforced the importance of comprehensive inspections, emphasizing regular monitoring of equipment and operators.

Technological innovations, such as advanced monitoring systems and automated inspection tools, are changing how inspections are conducted. The future trends indicate a greater integration of digital systems into crane operations, promising to increase efficiency and safety.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send crane operator daily inspection for eSignature?

How do I execute crane operator daily inspection online?

Can I edit crane operator daily inspection on an iOS device?

What is crane operator daily inspection?

Who is required to file crane operator daily inspection?

How to fill out crane operator daily inspection?

What is the purpose of crane operator daily inspection?

What information must be reported on crane operator daily inspection?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.