Get the free Material Safety Data Sheet

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Material Safety Data Sheet Form: A Comprehensive How-to Guide

Understanding the material safety data sheet (MSDS)

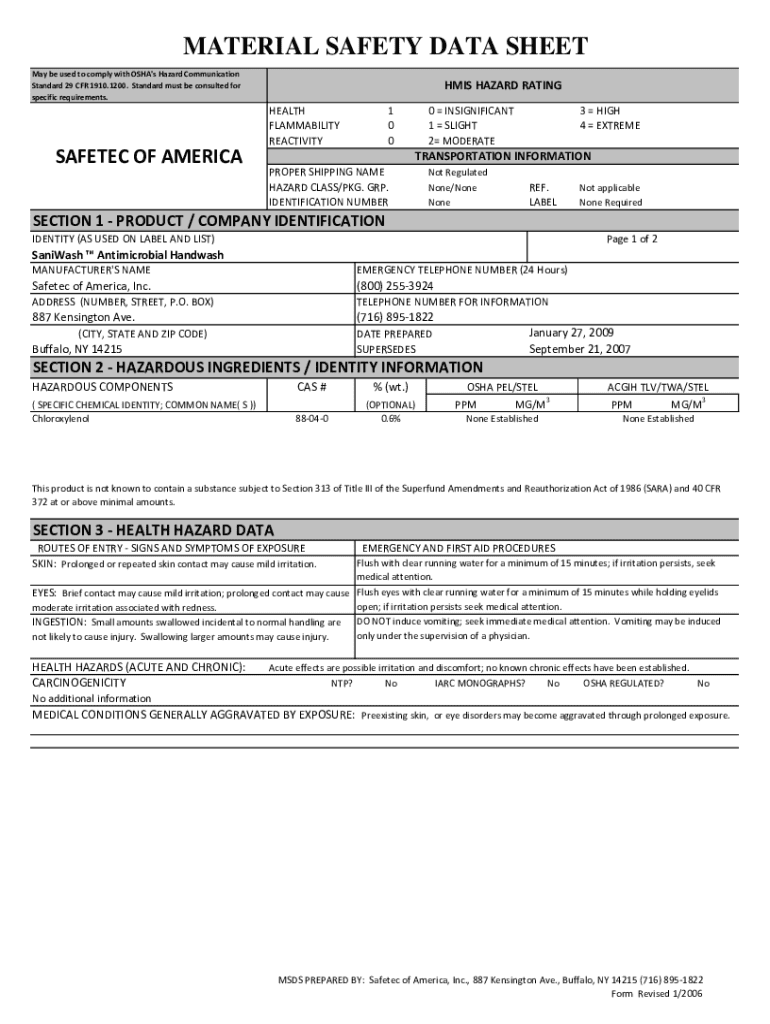

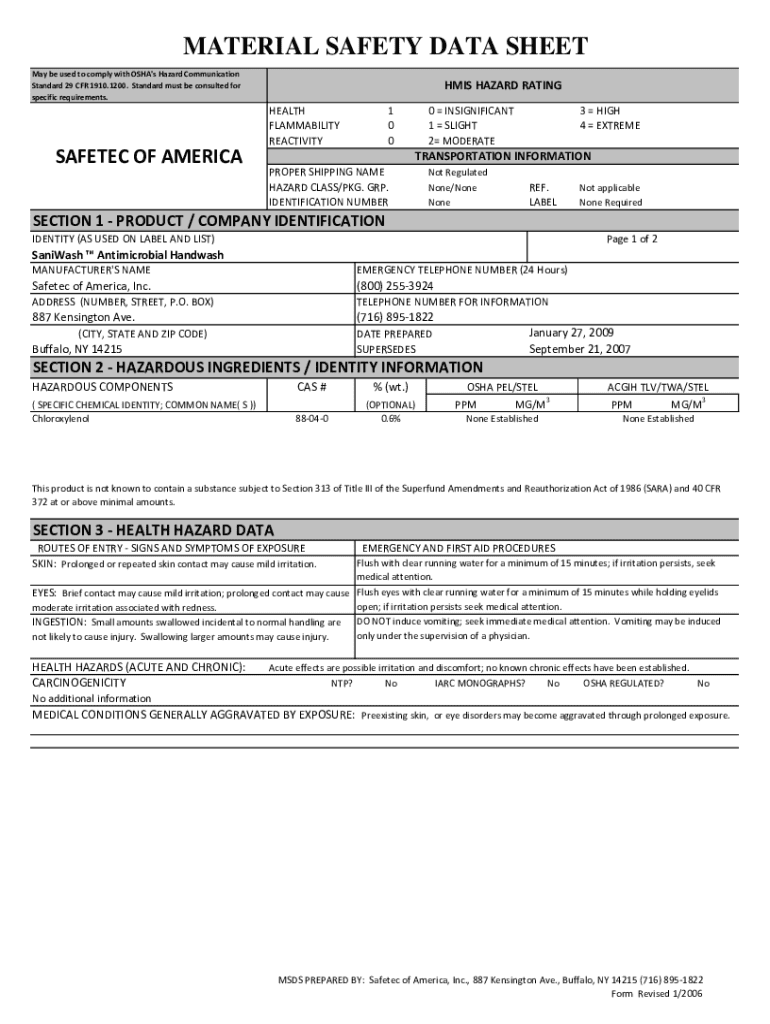

A Material Safety Data Sheet (MSDS) is a crucial document that provides safety information about materials used in the workplace. It outlines the properties of a chemical, including its hazards and safety precautions necessary for safe handling and use. The purpose of an MSDS is to inform workers and emergency personnel about the properties of the substances they may encounter in their jobs.

In terms of workplace safety, the MSDS plays a pivotal role in ensuring compliance with health and safety regulations. Understanding and utilizing MSDS effectively helps organizations mitigate risks related to exposure to hazardous chemicals. The Occupational Safety and Health Administration (OSHA) mandates that employers must maintain and make available MSDS for hazardous substances. This requirement underscores the importance of these sheets in protecting employees’ health and safety.

Globally harmonized system and its role

The Globally Harmonized System (GHS) for the classification and labeling of chemicals provides a standardized framework to communicate information about chemical hazards. This system significantly affects MSDS standards, transitioning them into Safety Data Sheets (SDS) with a more uniform format and labeling requirements worldwide. GHS ensures that chemical hazards are communicated consistently, improving safety for workers globally.

A defining aspect of the GHS is its use of pictograms which visually represent specific hazards associated with chemicals. These pictograms help workers quickly identify potential risks, making safety protocols more intuitive. For instance, a flame icon indicates flammable materials, while a skull and crossbones signal toxicity. The adoption of such symbols facilitates better understanding and adherence to safety guidelines, thereby enhancing workplace safety.

Structure of a material safety data sheet

A well-structured Material Safety Data Sheet is divided into specific sections, each serving a distinct purpose in conveying information about the material. Here’s a comprehensive breakdown of an MSDS's sections:

Filling out the material safety data sheet

Completing a Material Safety Data Sheet requires precise information gathering and attention to detail. Begin by collecting all relevant data about the material, including its properties, hazards, and safety recommendations. Utilize safety resources, chemical databases, and expert consultations to ensure accuracy. When entering this data, clarity is paramount — every section should be filled out clearly to prevent misinterpretation.

To streamline this process, using pdfFiller for MSDS completion can greatly enhance efficiency. The platform allows for easier data entry, making it simpler to format and organize the information correctly. When filling in the MSDS, remember to validate all input data against regulatory requirements to maintain compliance. This step is essential as inaccuracies can lead to serious safety breaches and potential legal issues.

Using pdfFiller to create and edit your MSDS

pdfFiller provides robust features for creating and managing Material Safety Data Sheets. Its cloud-based interface allows users to edit PDFs easily, ensuring that changes can be made on-the-go and accessed from any device. Leveraging templates can also provide consistency across different MSDS forms while maintaining compliance with industry standards.

An additional benefit of using pdfFiller is its eSigning capabilities, which facilitate the signing of official documents electronically. This feature not only speeds up the approval processes but also ensures documentation is securely stored and easily retrievable. Therefore, pdfFiller’s comprehensive tools are geared towards aiding professionals across industries in managing their MSDS effectively across various platforms.

Best practices for managing material safety data sheets

Maintaining up-to-date Material Safety Data Sheets is critical in ensuring workplace safety. Regular reviews and revisions should be an integral part of your safety policies — any changes in the chemical composition or regulatory guidelines necessitate an update to the MSDS. Establishing a tracking system can aid in monitoring the currency and accuracy of your MSDS documentation across different materials, ensuring compliance and accessibility.

In addition, promoting a culture of safety is key. Employees should be trained on the importance of using MSDS in their daily operations and understand how to access and utilize this information effectively. Engaging employees through safety drills or informational sessions can empower them and enhance their decision-making capabilities in critical situations.

Industry-specific use cases for MSDS

Material Safety Data Sheets are not only essential in the general business environment but have specific applications across various industries. In manufacturing settings, employees frequently handle chemicals, necessitating clear MSDS to mitigate risks. For laboratory environments, MSDS aids in precautionary measures against exposure risks, particularly when handling volatile substances.

Construction sites also require MSDS to ensure the safe use of materials and equipment. Additionally, in chemical handling and transportation, understanding the hazards through well-documented MSDS is critical to preventing accidents and ensuring regulatory compliance. Tailoring MSDS for specific industry practices enhances safety outcomes.

Addressing common challenges in MSDS management

Managing Material Safety Data Sheets comes with its own set of challenges. Compliance gaps can arise if employees are not equipped with the most updated information or do not understand how to interpret the MSDS accurately. Conducting regular training and audits can ensure employees remain informed and aware of potential hazards.

Additionally, navigating cross-departmental communication regarding MSDS updates can be difficult. Establishing clear lines of communication among departments responsible for safety, compliance, and operations is essential. This coordination can foster a more cohesive approach to managing hazardous materials and ensure that MSDS documents are promptly updated and easily accessible.

Interactive tools and resources

To effectively create and manage Material Safety Data Sheets, various interactive tools and resources are available. pdfFiller offers templates specifically designed for safety data sheets, reducing time spent on formatting while ensuring that all necessary sections are included. Additionally, utilizing interactive checklists can help validate that all required information is incorporated, ensuring comprehensive safety documentation.

Moreover, automation solutions can streamline the MSDS generation process, allowing for the quick updating and distribution of compliant sheets without manual intervention. Such tools enable businesses to focus on compliance and safety outcomes, maximizing overall efficiency in handling MSDS.

Enhancements to document workflow with pdfFiller

Integrating MSDS into existing document management systems can yield significant benefits. pdfFiller's capabilities allow companies to organize, retrieve, and manage MSDS efficiently within a unified platform. Leveraging APIs can ensure that updates across documents are synchronized, removing inconsistencies in hazardous material documentation.

Businesses that have successfully implemented pdfFiller for their MSDS management report improved compliance tracking and reduced overhead. Organizations can automate document workflows, from creation to storage to updates, ensuring that essential data is always accessible and current. This ultimately contributes to better decision-making and enhanced safety outcomes.

The future of material safety data sheets

The landscape of Material Safety Data Sheets is rapidly changing, with a growing emphasis on technological integration. Innovations in document automation and compliance are emerging. There’s a trend toward real-time data updates, allowing companies to incorporate the latest information into their MSDS instantly. This shift enhances risk management and ensures that safety protocols align with current regulations.

Expert insights indicate a focus on user-friendly interfaces for MSDS management software that ensures accessibility for all employees, not just specialists. Future MSDS practices are likely to prioritize interactive elements and accessibility, promoting a culture of safety. Companies that adapt to these trends will not only comply with regulations but also foster safer working environments.

Exploring other templates related to MSDS

Beyond the Material Safety Data Sheet, there are numerous other forms pertinent to health and safety compliance that businesses should consider. With increasing regulations around workplace safety, having various templates tailored for different scenarios is beneficial. Forms such as chemical inventory logs, incident reporting, and safety audit checklists complement the safety framework established by the MSDS.

Utilizing tailored solutions for specific industries managing hazardous materials will enhance overall safety compliance. pdfFiller’s extensive library of templates and document management features supports organizations in maintaining compliance with industry standards across diverse sectors.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send material safety data sheet for eSignature?

How do I edit material safety data sheet online?

How do I complete material safety data sheet on an iOS device?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.