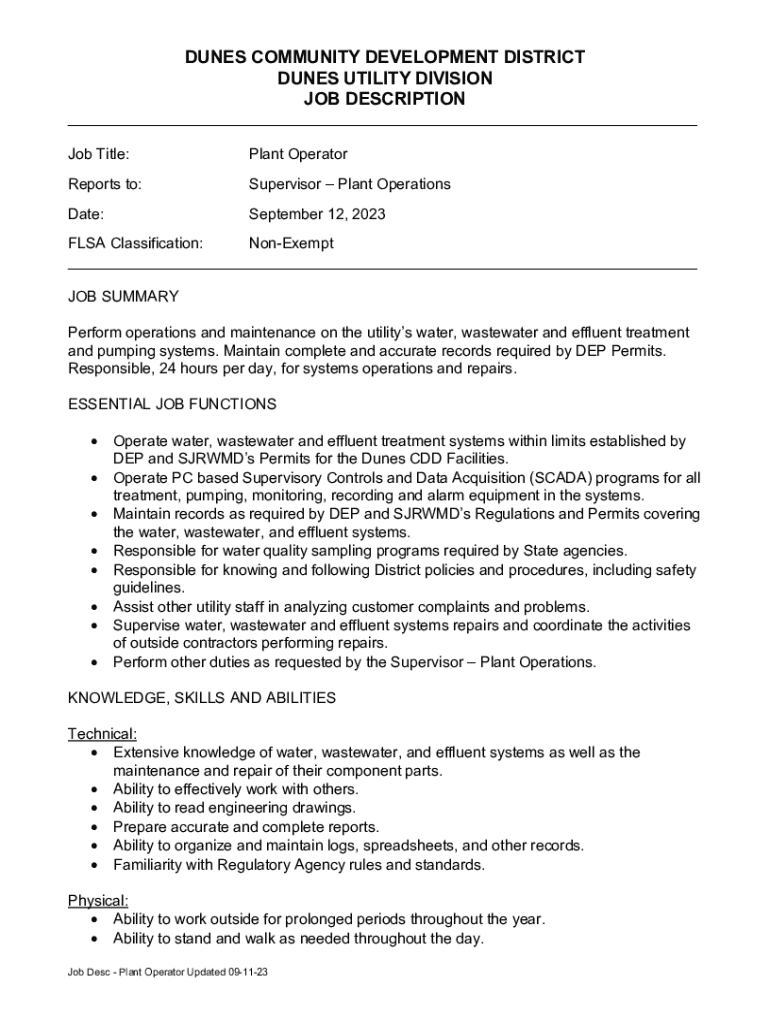

Get the free Plant Operator Job Description

Get, Create, Make and Sign plant operator job description

How to edit plant operator job description online

Uncompromising security for your PDF editing and eSignature needs

How to fill out plant operator job description

How to fill out plant operator job description

Who needs plant operator job description?

Comprehensive Guide to Plant Operator Job Description Form

Overview of the plant operator role

A plant operator is a vital role within various industrial settings, responsible for overseeing the day-to-day operations of production facilities. These individuals manage and monitor equipment that processes materials, ensuring production levels meet organizational targets while maintaining a safe work environment.

Plant operators are essential in industries such as power plants, oil refineries, and chemical plants, where efficiency and safety are paramount. Their role has grown increasingly important in today's fast-paced manufacturing environment, necessitating a well-structured job description to attract the right candidates.

Roles and responsibilities of a plant operator

The daily responsibilities of a plant operator are wide-ranging and critical for the smooth operation of facilities. They monitor production processes, constantly checking equipment and systems to ensure optimal performance.

Operators must also conduct routine maintenance and troubleshooting of machinery and equipment, addressing any issues that may arise. This requires a strong understanding of how plant processing equipment functions and the ability to quickly resolve problems to minimize downtime.

Safety is paramount in this role. Plant operators are tasked with following safety protocols and compliance regulations to safeguard themselves and their colleagues. They must also be adept at managing control systems, ensuring that all processes adhere to operational standards.

Collaboration is another key aspect of the role, as plant operators regularly interact with supervisors and other staff to ensure that production goals are met.

Key qualifications for plant operators

Key qualifications for plant operators typically include specific educational requirements and essential technical skills. At a minimum, candidates should hold a high school diploma, although an associate's degree in a related field can enhance their opportunities.

Certifications can significantly boost a candidate's profile. For example, a Process Operator Certification demonstrates competence in operating and maintaining complex plant systems, making individuals more attractive to potential employers.

On the technical side, mechanical aptitude is crucial for understanding plant processing equipment and machinery. Additionally, proficiency in computer systems is increasingly important, given the reliance on integrated control systems in modern plants.

Soft skills such as problem-solving abilities, effective communication, and teamwork are just as vital. Operators often work in teams and must effectively communicate any issues or changes to their colleagues and supervisors.

Plant operator work environment and schedule

The work environment for plant operators can vary widely, depending on the type of establishment. Most plant operators work in industrial settings, which may range from clean and well-organized manufacturing facilities to more demanding environments, such as oil refineries or chemical plants, where safety concerns are prominent.

Typical working conditions include a combination of indoor and outdoor settings, with operators frequently moving between the control room and the production area. The nature of their work means they must occasionally work in challenging conditions, such as heat or noise, especially in facilities that process heavy materials or chemicals.

Most plant operators work in shifts, with 24/7 operations being common in industries such as power generation and manufacturing. This may involve rotating shifts, night shifts, or extended hours during peak production times.

Safety considerations are critical, requiring operators to don protective gear and adhere to strict safety protocols. Working under pressure is also a part of the job, as operators must remain focused and respond to any unforeseen situations quickly.

Salary and benefits expectations

Salaries for plant operators can vary significantly based on geographic location, industry, and experience. In the United States, the average salary ranges widely, with operators earning anywhere from $30,000 to $80,000 annually, depending on factors like the complexity of the operations and the level of responsibility.

Regions also play a significant role in determining salary levels. For example, plant operators in urban areas or regions with a high demand for skilled workers often command higher salaries than those in rural locations.

In addition to salary, numerous benefits are typically offered to plant operators. Common benefits include health insurance, retirement plans, paid time off, and opportunities for professional development or training.

Essential components of a plant operator job posting

Crafting an effective job posting for a plant operator is crucial to attracting qualified candidates. A clear job title should reflect the responsibilities and expectations associated with the role.

The job summary should provide a concise overview of the position, emphasizing essential responsibilities and skills needed. Following this, a focused section outlining the specific responsibilities can guide applicants in understanding what will be expected of them.

A clearly defined section for required skills and qualifications is essential to set expectations. Additionally, including insights into company culture and mission statements can help candidates determine if they align with the organization's values. Encouraging diversity and inclusion through wording choices is also vital to creating an equitable workplace.

Tips for writing an effective plant operator job posting

To write an effective job posting, focus on structuring information logically. Start with an engaging introduction that draws in potential applicants. Use clear headings and bullet points to make the content easily scannable, allowing candidates to quickly find relevant information.

Incorporating compelling language can significantly enhance the appeal of the job posting. Highlight opportunities for growth and development within the organization, showcasing how candidates can advance their careers.

Consider including specific qualities that make your company unique or distinguishing attributes of the role. This will not only attract more qualified applicants but also ensure they align with the operational goals of your establishment.

Preparing for plant operator interviews

When preparing for interviews for the plant operator position, candidates should anticipate a range of questions designed to assess their technical knowledge and problem-solving abilities. Common situational questions might involve scenarios related to equipment malfunctions or production issues, testing the candidate's approach to problem resolution.

Technical knowledge is another critical aspect of interviews. Candidates could be asked to demonstrate their understanding of specific equipment or processes, illustrating their expertise in handling day-to-day operations effectively.

Employers typically seek attributes such as adaptability, critical thinking, and a strong focus on safety. Candidates should prepare responses that reflect their experiences and capabilities in these areas.

Related job titles and descriptions

Understanding related job titles can help employers and candidates alike navigate the landscape of plant operations. For example, roles such as chemical plant operators focus specifically on processing chemicals and managing related equipment. Meanwhile, operations specialists may handle broader responsibilities that include overseeing multiple aspects of plant operations.

It's also beneficial to compare the job descriptions and responsibilities across these positions. While there is often overlap in required skills and knowledge, specific areas of focus may vary based on the type of plant and industry.

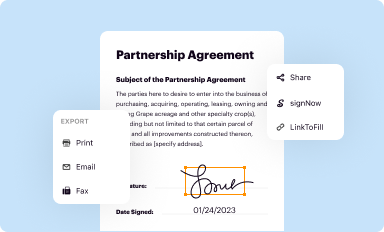

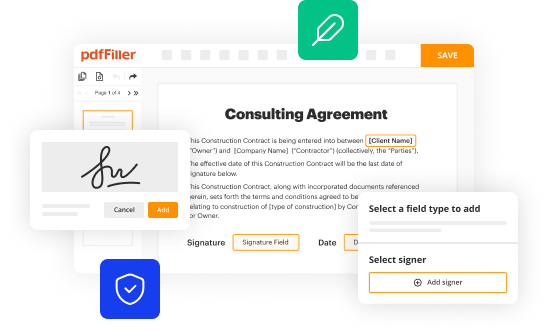

Leveraging technology in documentation

Utilizing cloud-based solutions, such as pdfFiller, for job description creation streamlines the documentation process, allowing HR teams to easily edit, sign, and manage job postings remotely. This technology enhances collaboration among team members, facilitating real-time updates and feedback.

The advantage of using a cloud-based document management system is evident when it comes to tracking changes and maintaining records of job postings. This ensures that all team members are on the same page and can contribute to creating an accurate and effective job description.

Interactive tools within cloud platforms further enhance the user experience, allowing HR professionals to collaborate more effectively on edits and revisions, making it easier to adapt job postings as needed.

Appendix: Template for plant operator job description form

Creating a structured job description form can significantly enhance the recruiting process. Below is a sample structure that can be tailored to meet specific needs when hiring for a plant operator position.

The template should include editable fields that allow for customization based on the unique requirements of the organization. Key components such as job title, summary, responsibilities, required qualifications, and company culture should be clearly defined.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send plant operator job description for eSignature?

How do I complete plant operator job description online?

How do I edit plant operator job description online?

What is plant operator job description?

Who is required to file plant operator job description?

How to fill out plant operator job description?

What is the purpose of plant operator job description?

What information must be reported on plant operator job description?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.