Get the free Microchannel Heat Exchanger: Cgaf-mche-oem

Get, Create, Make and Sign microchannel heat exchanger cgaf-mche-oem

Editing microchannel heat exchanger cgaf-mche-oem online

Uncompromising security for your PDF editing and eSignature needs

How to fill out microchannel heat exchanger cgaf-mche-oem

How to fill out microchannel heat exchanger cgaf-mche-oem

Who needs microchannel heat exchanger cgaf-mche-oem?

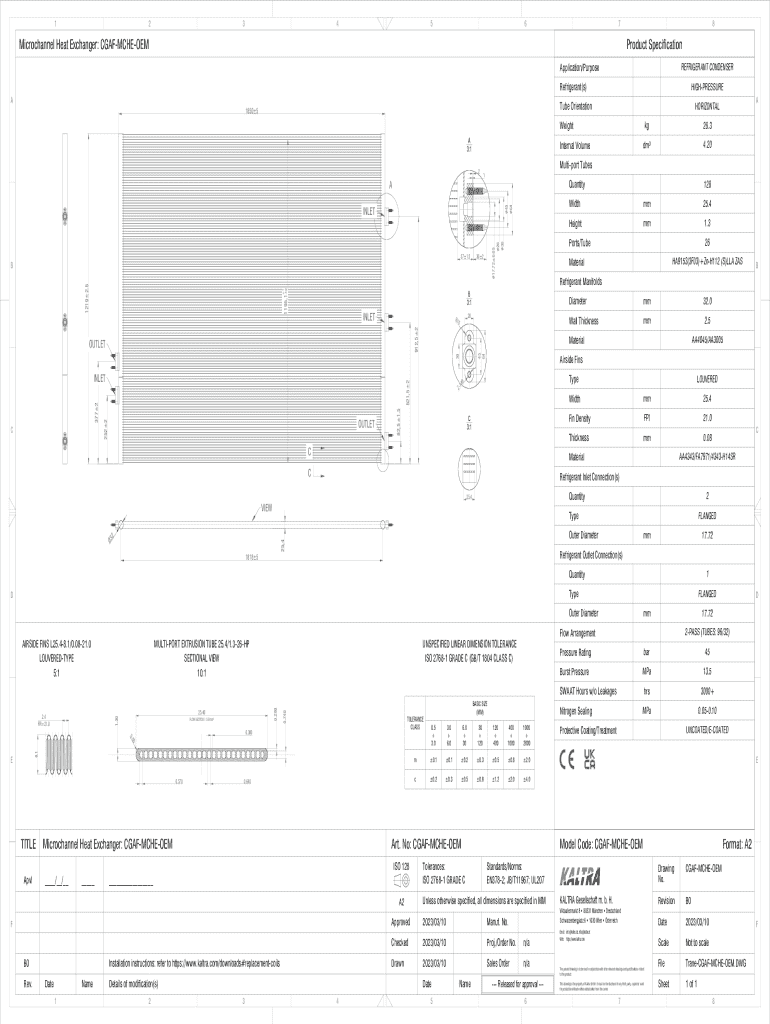

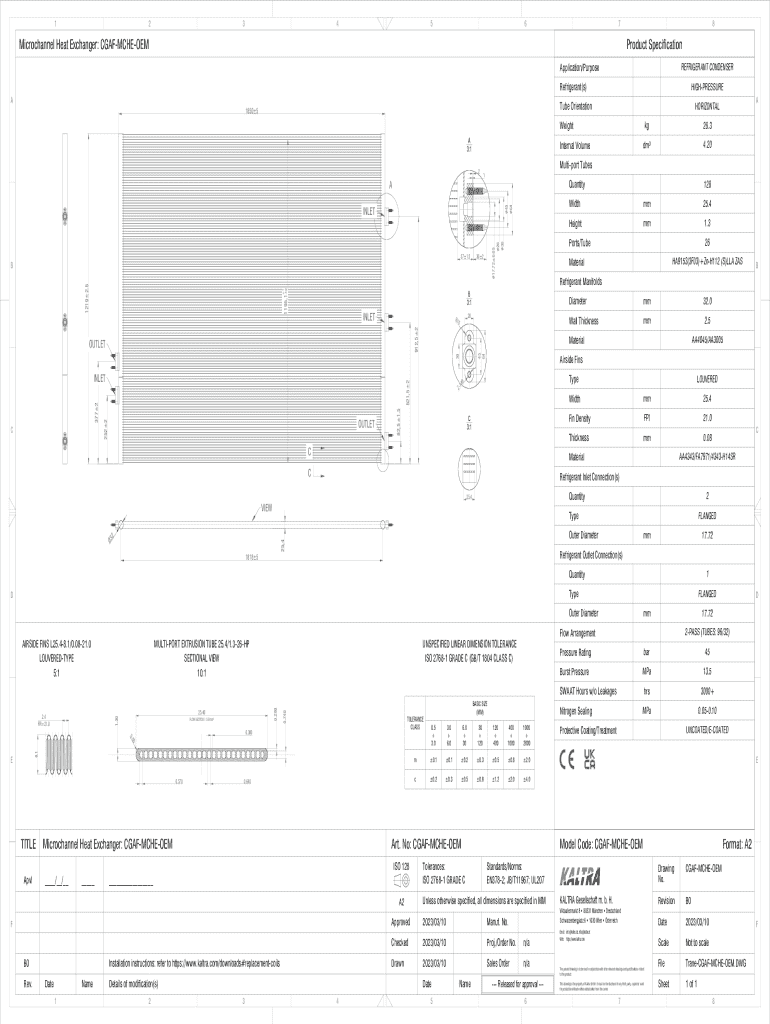

Understanding the Microchannel Heat Exchanger CGAF-MCHE-OEM Form

Overview of microchannel heat exchangers

Microchannel heat exchangers are a modern innovation in thermal management technology particularly used in HVAC and refrigeration systems. These compact devices utilize narrow channels to facilitate heat transfer, boasting efficiency gains due to their large surface area relative to volume. By employing microchannel technology, users can achieve substantial reductions in the refrigerant charge, leading to improved operational efficiency and reduced environmental impact.

The importance of microchannel heat exchangers in engineering arises from their ability to enhance energy efficiency while minimizing weight and size. Traditional heat exchangers, which rely on expanded metal tubes and larger dimensions, often fall short of these criteria. The microchannel design, characterized by flat tube construction and lower fluid volumes, ensures faster heat transfer rates and allows for enhanced system performance.

Key features of the CGAF-MCHE-OEM form

The CGAF-MCHE-OEM form is specifically designed for the efficient specification and documentation of microchannel heat exchangers. It serves to streamline the process of gathering essential information required by manufacturers and engineers. By providing a structured framework, the form assists teams in ensuring all necessary parameters for custom microchannel designs are accounted for.

Target applications for the CGAF-MCHE-OEM form include HVAC systems, commercial refrigeration, and automotive cooling systems. Its design accommodates the specific requirements that these industries demand, ensuring optimal performance and regulatory compliance. Properly utilizing the CGAF-MCHE-OEM form leads to expected outcomes such as improved communication with manufacturers, reduced design errors, and enhanced product performance.

Step-by-step guide to filling out the CGAF-MCHE-OEM form

Filling out the CGAF-MCHE-OEM form can seem daunting at first glance, but following a structured approach simplifies the process. Below is a step-by-step guide to ensure accuracy and completeness.

Step 1: Gather necessary information

Before accessing the form, compile essential specifications such as materials, dimensions, and project requirements. Documentation needs may also include schematics of the heat exchanger configuration and performance expectations.

Step 2: Accessing the form

The CGAF-MCHE-OEM form can be easily located on pdfFiller. Users can navigate to the search bar and enter the specific form name, or browse through the engineering templates section.

Step 3: Filling out the form

When filling out the form, it is important to approach this field by field. Key sections typically include client information such as name and contact details, project specifics, and technical requirements like cooling capacity and dimensions. Ensure precision in these entries to avoid complications later on.

Step 4: Reviewing entries for accuracy

Before submitting the form, take time to verify all entries. This verification process is crucial as common errors include incorrect dimensions or specifications that can lead to manufacturing delays. Double-check numeric values, ensure all fields are complete, and cross-reference with your initial information.

Step 5: Submitting the form

The form can be submitted via various methods depending on project requirements, including online submission through pdfFiller, email, or even physical mail if necessary. After submission, always confirm receipt with the intended recipient to ensure that your specifications are being processed.

Editing and customizing the CGAF-MCHE-OEM form

pdfFiller offers various options for editing the CGAF-MCHE-OEM form. Users have access to tools that allow for flexible modification of the document layout and content, ensuring that each submission can be tailored to meet specific project requirements.

The platform’s template customization features enable users to modify fields, add branding elements, or even adjust structural layouts to best fit their organizational needs. For teams working on collaborative projects, pdfFiller supports multiple user access, facilitating joint efforts on form completion without version control issues.

eSigning the CGAF-MCHE-OEM form

Using digital signatures for the CGAF-MCHE-OEM form enhances the efficiency of your documentation process. Digital signatures provide a secure and legally binding way to authenticate your documents without the need for physical paperwork.

The eSigning process through pdfFiller is straightforward. Users can simply click on the designated ‘eSign’ button, follow the prompts to create or insert their digital signature, and finalize the document with just a couple of clicks. It’s important to ensure compliance with digital signature laws to maintain the integrity of your agreements.

Managing your completed forms

Once the CGAF-MCHE-OEM form is filled and submitted, managing completed documents effectively is critical. pdfFiller allows users to store and organize their documents systematically, ensuring that all important forms are easily accessible when needed.

The platform offers robust features for accessing previous submissions and a powerful search functionality that allows users to quickly retrieve forms based on keywords or specific project details. This streamlined approach not only saves time but also enhances overall productivity across teams.

Common FAQs about microchannel heat exchangers and the CGAF-MCHE-OEM form

Several frequently asked questions arise regarding the CGAF-MCHE-OEM form and its applications. For instance, if changes are needed after submission, it is crucial to contact the manufacturer or service provider immediately to ensure that the modifications are documented correctly.

Another common inquiry involves the applicability of the form across different microchannel heat exchanger designs. The CGAF-MCHE-OEM form is versatile and can be tailored to most types of microchannel designs; however, it’s beneficial to consult with relevant industry standards and guidelines to ensure compliance.

User success stories: case studies

Real-world examples of utilizing the CGAF-MCHE-OEM form reveal significant improvements in project efficiency. Teams that employed the form have reported reduced turnaround times and fewer errors in specifications, translating to smoother project execution.

Testimonials from users underline the impact of the CGAF-MCHE-OEM form on their workflows. One user remarked on how employing this structured documentation has facilitated clearer communication with manufacturers, directly correlating to project success and timely completions. Such stories illustrate the practical value of leveraging this form in the ever-evolving field of engineering.

Related products and templates on pdfFiller

pdfFiller also offers various related forms and templates that are beneficial for heat exchanger documentation and HVAC projects. From technical inspection forms to standard project documentation templates, users can access a comprehensive suite of resources.

These related engineering templates not only assist in preparing your documentation but also assure compliance with industry standards. Innovations in document management solutions offered at pdfFiller further enhance user experience, making it easy to create, edit, and manage engineering documents efficiently.

Additional insights into microchannel heat exchangers

The landscape of heat exchanger technology is rapidly evolving, with ongoing innovations aimed at further enhancing efficiency and sustainability. Microchannel designs are at the forefront due to their potential for lower energy consumption and improved environmental performance.

As industries continue to embrace eco-friendly practices, the shift toward advanced heat exchangers like microchannel systems illustrates a commitment to environmental responsibility. With the integration of smart technologies, the future of HVAC systems is poised for transformative improvements that will resonate throughout the industry and benefit end-users.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send microchannel heat exchanger cgaf-mche-oem to be eSigned by others?

How can I fill out microchannel heat exchanger cgaf-mche-oem on an iOS device?

How do I complete microchannel heat exchanger cgaf-mche-oem on an Android device?

What is microchannel heat exchanger cgaf-mche-oem?

Who is required to file microchannel heat exchanger cgaf-mche-oem?

How to fill out microchannel heat exchanger cgaf-mche-oem?

What is the purpose of microchannel heat exchanger cgaf-mche-oem?

What information must be reported on microchannel heat exchanger cgaf-mche-oem?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.