Get the free Specification for Axial Piston Pump for Hp Bypass Oil System

Get, Create, Make and Sign specification for axial piston

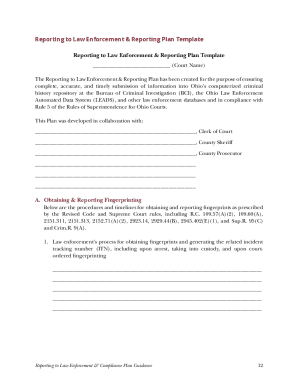

How to edit specification for axial piston online

Uncompromising security for your PDF editing and eSignature needs

How to fill out specification for axial piston

How to fill out specification for axial piston

Who needs specification for axial piston?

Specification for Axial Piston Form: A Comprehensive Guide

Understanding the axial piston form

The axial piston form is central to hydraulic systems, primarily serving as a mechanism in pumps and motors. Utilizing pistons arranged parallel to the drive shaft, this design converts rotational energy into linear energy with high efficiency. The precision of this technology is pivotal in applications ranging from industrial machinery to automotive systems. In these environments, like the automotive sector, the need for precise specifications is clear—enhancing performance and durability.

With an emphasis on high pressure and varied displacement volumes, axial piston systems offer a critical performance advantage. The need for accuracy in specifications stem from the significant mechanical stresses these systems encounter. Deviation from optimal specifications can lead to inefficiencies, increased wear, or even catastrophic failures. Thus, understanding the axial piston form becomes essential for engineers and design professionals.

How to create a specification for axial piston form

Creating an effective specification for axial piston forms requires a detailed understanding of essential components. Key elements include displacement range, which dictates the volume of fluid moved per revolution, and pressure ratings, indicating the maximum operational pressure the system can withstand. Additionally, temperature limits are crucial to ensure the components can operate under varying thermal conditions without degradation.

Construction materials also play a significant role. Options like stainless steel or specialized alloys offer corrosion resistance and longevity in fluid environments, which is crucial for maintaining system integrity. Optional features such as vibration dampening can further enhance performance, particularly in environments with high levels of operational noise.

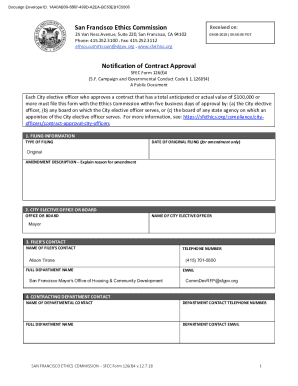

Utilizing interactive tools available on pdfFiller can streamline this process. The platform allows engineers to design and modify specifications effortlessly, accommodating varying needs and preferences. With templates specifically tailored for axial pistons, users can ensure accuracy and completeness in their documentation.

Components of an axial piston mechanism

At the heart of the axial piston mechanism is the swashplate, which plays a pivotal role in the transformation of rotary motion into linear force. The angle of the swashplate alters the displacement for each piston, enabling variability in output flow and pressure, thus improving efficiency across a range of applications. This adaptability is essential, particularly in industries that demand precise control over hydraulic systems.

Moreover, the arrangement of cylinders and pistons significantly impacts the system’s overall efficiency. A proper alignment minimizes friction and maximizes power transfer, ensuring that each stroke effectively contributes to the system's output. In contrast, misalignments can lead to performance drops and increased wear on components. Similarly, the inlet and outlet mechanisms must be designed with attention to fluid dynamics to optimize flow rates and prevent issues such as cavitation, which may hinder performance.

Filling out axial piston specifications

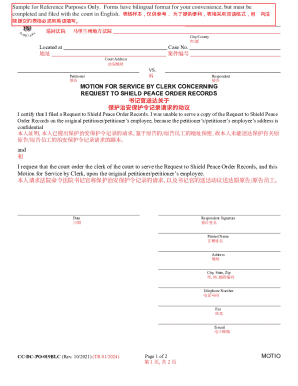

Filling out specifications for axial piston systems can be a straightforward process with the right tools. Start by accessing the relevant form template on pdfFiller. Ensure proper selection of fields that require input, such as displacement volume and pressure ratings, to create a specification that accurately reflects your requirements.

Input specifications correctly by following a systematic approach. After entering necessary details, it's crucial to review and edit completed forms to ensure all information is accurate and comprehensive. Any discrepancies can lead to performance issues, negating the advantages of precise specifications. Additionally, pdfFiller offers tools that assist in validating and editing these specifications, ensuring that users can collaborate effectively and resolve potential inconsistencies.

Analyzing axial piston performance

Efficiency in axial piston systems is heavily influenced by the accuracy of specifications. Discrepancies between specified and actual operating conditions can lead to reduced fluid dynamics performance. Factors like fluid viscosity, temperature variations, and operational pressures play critical roles in how well a system performs. Engineers must prioritize precise specifications to avoid common performance setbacks.

Common performance issues such as cavitation and leakage are often symptoms of specification misalignment. Cavitation, for instance, occurs when the local pressure of the hydraulic fluid drops below its vapor pressure, leading to bubble formation and severe damage to the mechanism. Ensuring that systems are rated for the correct pressure and performance specifications can significantly reduce the likelihood of these issues.

Choosing between axial and radial piston forms

When deciding between axial and radial piston forms, understanding comparative advantages is crucial. Axial piston systems feature a more straightforward design and generally offer higher efficiency, making them suitable for high-speed applications. Conversely, radial piston pumps can accommodate higher pressures and are effective in heavy-duty situations, such as hydraulic presses and industrial machinery.

Situational applications further define the choice. For instance, if your application demands compact design and precise control, an axial piston system would be more advantageous. On the other hand, situations requiring robust performance under strenuous conditions may warrant the use of radial pistons.

Troubleshooting common problems in axial piston systems

Recognizing inefficiencies in axial piston systems is foundational for successful troubleshooting. Symptoms may include unusual noise, irregular pressures, and reduced output. Particularly, fluctuations in pressure may indicate leaks, while persistent noise can suggest internal mechanical issues. Identifying these early can prevent larger, more costly system failures.

Once symptoms are identified, practical remediation strategies can be employed. A thorough inspection and validation of specifications can highlight potential misalignments or damaged components. Regular maintenance practices—like replacing worn-out seals and verifying fluid levels—are essential to maintaining system health and extending operational lifecycle. Additionally, using models and simulations to predict system behaviors can also uncover hidden inefficiencies.

Frequently asked questions (FAQ)

What are the standard tolerances for axial piston specifications? Ideally, tolerances can vary by application, but general guidelines suggest deviations of no more than 2-3% in critical dimensions to maintain performance. How does fluid dynamics affect piston performance? Proper fluid flow rates, viscosity levels, and temperature conditions are all critical to piston performance; mismatching any of these parameters can lead to decreased efficiency.

What maintenance practices ensure the longevity of axial piston systems? Regular checks on hydraulic fluid quality, seal integrity, and overall system cleanliness are vital. Also, timely replacement of worn parts can prevent catastrophic failures. How can I edit my specification on pdfFiller after initial submission? Users can navigate to their stored documents on pdfFiller's dashboard, where they can access, edit, and resubmit forms easily.

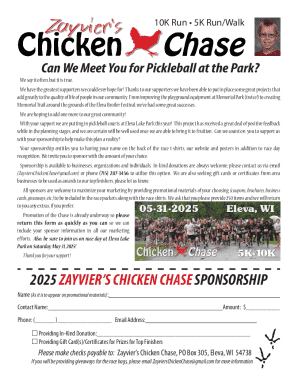

Real-world applications of axial piston specifications

Today, axial piston specifications find relevance across various industries. For instance, in automotive applications, these systems power hydraulic brakes and steering mechanisms, requiring precise operational specifications to ensure safety and performance. In manufacturing, axial pistons are often integral to robotic systems, ushering in necessary precision and adaptability.

Innovations in axial piston technology are also shaping the future landscape. As industries increasingly demand efficiency and sustainability, axial piston designs are evolving. Modern advancements include smart components that integrate sensor technology for real-time monitoring and feedback, allowing systems to adapt dynamically and optimize based on performance metrics achieved during operation.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit specification for axial piston in Chrome?

Can I edit specification for axial piston on an iOS device?

How do I complete specification for axial piston on an Android device?

What is specification for axial piston?

Who is required to file specification for axial piston?

How to fill out specification for axial piston?

What is the purpose of specification for axial piston?

What information must be reported on specification for axial piston?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.