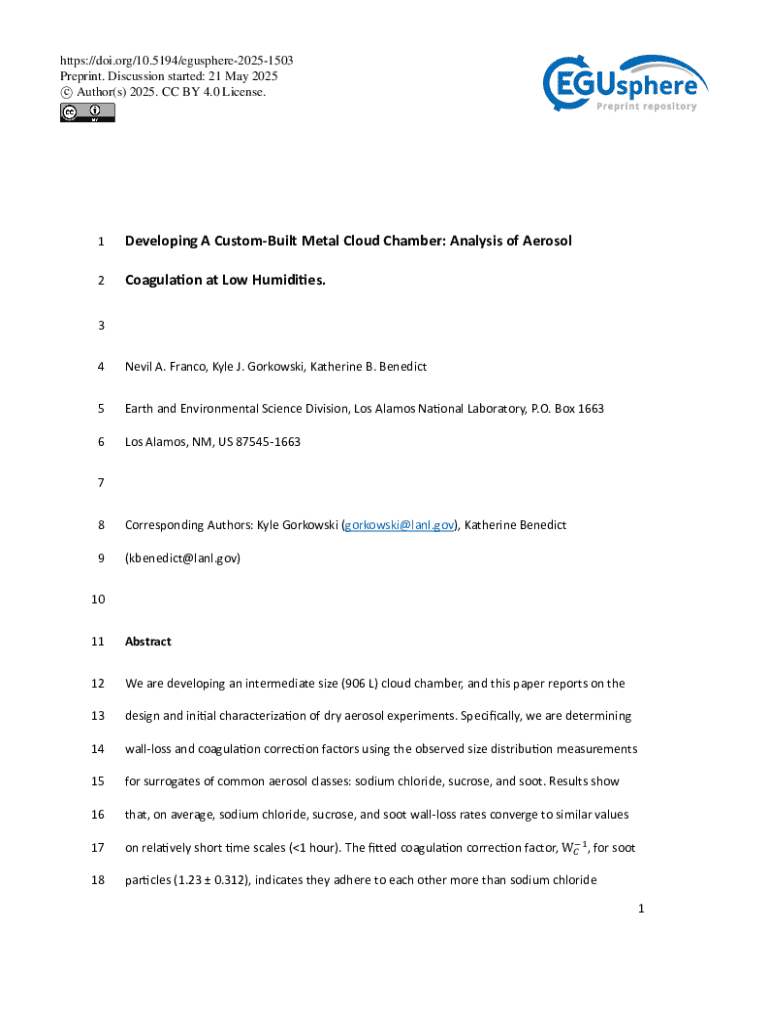

Get the free Developing A Custom-Built Metal Cloud Chamber: Analysis of ...

Get, Create, Make and Sign developing a custom-built metal

Editing developing a custom-built metal online

Uncompromising security for your PDF editing and eSignature needs

How to fill out developing a custom-built metal

How to fill out developing a custom-built metal

Who needs developing a custom-built metal?

Developing a Custom-Built Metal Form: A Comprehensive Guide

Understanding the need for custom metal forms

Custom metal forms play a critical role in a variety of industries such as automotive, aerospace, and manufacturing. These forms are essential for creating parts that meet specific specifications, ensuring precision and quality. Without custom metal forms, companies may struggle to produce complex components that function effectively and efficiently. In today's competitive landscape, having the ability to manufacture unique metal components can set a business apart from its competitors.

Key considerations when developing a custom-built metal form

A thoughtful approach is crucial when developing a custom-built metal form. The first consideration is material selection. Depending on the application, materials like aluminum, steel, or titanium may be appropriate, each offering distinct advantages such as weight, strength, and corrosion resistance. Together with material selection, understanding the design specifications is key. This involves determining the thickness and dimensions of the form, which will directly impact manufacturing processes and costs.

Tolerances and accuracy are also vital. Precision manufacturing demands tight tolerances to ensure that parts fit and function properly once assembled. This requires a budget that accommodates not just material costs but also design and fabrication expenses. All these factors contribute to the final decision-making process, ensuring that your project remains economically viable while offering the necessary performance.

The design process for custom metal forms

Embarking on the design process begins with initial concept development, where brainstorming sessions allow teams to explore features and functionalities. Engaging with various stakeholders ensures that the resulting design aligns with operational expectations. Once a concept is formed, utilizing CAD software becomes paramount. CAD tools enhance visualization and allow for detailed design iterations, bringing concepts to life.

Adopting best practices, such as maintaining design consistency and considering manufacturability, can significantly impact the success of the final product. After the design phase, prototyping is an invaluable step. Employing rapid prototyping techniques, such as 3D printing, allows for early-stage feedback. Iterating on the prototype based on stakeholder insights ensures the end design meets all user requirements and expectations.

Fabrication techniques for custom metal forms

Fabrication processes are the backbone of metal form development. A thorough understanding of these manufacturing processes is essential for selecting the right technique. Cutting methods like laser cutting services and waterjet cutting are popular for their precision and flexibility, allowing for varied designs and thicknesses. Bending techniques are equally important, providing the ability to shape metal without compromising structural integrity.

Welding is another crucial aspect, where choosing the right welding method—be it MIG, TIG, or spot welding—depends on material types and desired strength. Machining processes further augment precision customization, allowing for the production of intricate details in the form. Finally, applying finishing options such as surface treatments and textures can improve durability and aesthetics, making it an essential step in achieving functional and visually appealing products.

Quality control measures in the custom metal form development

Implementing stringent quality control measures is crucial throughout the custom metal form development process. One of the primary objectives is ensuring dimensional accuracy, which encompasses rigorous testing at various manufacturing stages. Common testing methods, such as coordinate measuring machines (CMM) and visual inspections, help identify potential discrepancies early on.

Moreover, testing for strength and durability is non-negotiable, as finished parts must adhere to industry standards. Compliance ensures product reliability and safety, which helps to foster customer trust. Documenting the quality assurance process not only fulfills legal and compliance requirements but also reinforces the credibility of your development process.

Utilizing technology for enhanced custom form development

Embracing technology within custom metal form development can significantly enhance overall efficiency. Cloud-based collaboration tools allow teams to work together, accessing design files, communicating in real-time, and managing revisions effectively regardless of location. This is particularly beneficial for projects with multiple stakeholders, as it facilitates seamless communication and ensures everyone is aligned.

Integrating feedback and revisions in real time prevents costly errors and improves the design evolution process. Utilizing project management software can further aid in managing multiple projects efficiently, keeping track of timelines, resources, and responsibilities.

Engaging with suppliers and fabricators

Collaborating effectively with suppliers and fabricators is fundamental to the success of your custom metal form projects. Identifying potential suppliers involves assessing their capabilities, experience, and track record in delivering quality products on time. It’s essential to evaluate multiple vendors to ensure you find the best fit for your specific needs.

Negotiating terms and establishing solid relationships can create a more productive working environment, ensuring open lines of communication. Understanding lead times and production schedules is critical, as it allows for proper project planning and resource allocation.

Practical tips for filling out and managing your custom metal forms

Organizing documentation is essential for managing custom metal forms effectively. Utilizing pdfFiller can streamline this process by allowing users to edit, collaborate on, and eSign important documents all in one place. With pdfFiller, you can easily edit and annotate metal form documents, ensuring that all stakeholders have access to the latest iterations.

Additionally, pdfFiller facilitates document security, enabling you to eSign crucial files safely. Maintaining organized documentation throughout the process not only helps in keeping track of each project's progress but also aids in future audits and assessments.

Success stories: real-world applications of custom metal forms

Examining success stories can provide valuable insights into the potential of custom metal forms. In the automotive industry, a notable project involved the development of a custom body frame that improved structural integrity while reducing weight. This not only enhanced vehicle performance but also contributed to fuel efficiency, showcasing the impact of innovative designs.

Similarly, the aerospace sector has seen significant innovations, such as specialized components crafted to withstand extreme conditions while being lightweight. These advancements have propelled aerospace capabilities forward, demonstrating the importance of tailored solutions. Lessons learned from each project emphasize the necessity of a precise design approach, collaboration with skilled suppliers, and robust quality control measures.

Next steps: taking your custom metal form projects forward

As you embark on the journey of developing custom metal forms, planning for future developments is imperative. Leveraging interactive tools not only improves project outcomes but also facilitates continuous learning within your team. Staying informed about emerging technologies, materials, and best practices will position your projects for long-term success.

Building a network of resources and support will empower your teams to tackle challenges effectively. Engaging with professional communities and forums can provide insights into trends and innovations, ensuring that your next custom metal form project is even more successful.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send developing a custom-built metal for eSignature?

How do I make edits in developing a custom-built metal without leaving Chrome?

Can I edit developing a custom-built metal on an Android device?

What is developing a custom-built metal?

Who is required to file developing a custom-built metal?

How to fill out developing a custom-built metal?

What is the purpose of developing a custom-built metal?

What information must be reported on developing a custom-built metal?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.