Get the free Microstructural Parameters for Modelling of Superconducting Foams - universaar uni-s...

Get, Create, Make and Sign microstructural parameters for modelling

How to edit microstructural parameters for modelling online

Uncompromising security for your PDF editing and eSignature needs

How to fill out microstructural parameters for modelling

How to fill out microstructural parameters for modelling

Who needs microstructural parameters for modelling?

Microstructural parameters for modelling form

Understanding microstructural parameters

Microstructural parameters are crucial components in materials science that define the intricate features and structures within a material at the microscopic level. These parameters influence not just the physical properties of materials but also their mechanical and thermal behaviors. By accurately modeling these microstructural characteristics, researchers and engineers can predict how materials will respond under various conditions, which is vital for fields such as aerospace, automotive, and biomedical engineering.

Key microstructural parameters

Understanding specific microstructural parameters can significantly enhance modeling accuracy. Key parameters include:

Relevance to document modeling

Transitioning these microstructural concepts to digital document design is essential, particularly when creating documents that convey complex material information. Understanding how structuring affects user interaction can dramatically enhance document usability. Factors such as layout, flow, and clarity become paramount as they influence how a reader interprets microstructural data, ultimately enhancing comprehension and the overall effectiveness of documentation.

The process of modeling microstructural parameters

Modeling microstructural parameters begins with selecting the right parameters relevant to the material of interest. This selection process involves identifying the key characteristics your form or model needs based on the specific application and intended use. For example, an aerospace component may focus more on grain size and porosity, while a biomedical device might prioritize phase composition and crystallography.

Data collection techniques

Accurate data collection is pivotal in modeling microstructural parameters effectively. Various techniques are available, including:

Ensuring the accuracy of data collection is critical as it directly impacts model reliability. Thus, validation of experimental results against simulated data can provide a sound basis for modeling efforts.

Tools and methods for effective modelling

For effective modeling of microstructural parameters, several software tools can facilitate the process, each offering unique functionality. For example, Finite Element Analysis (FEA) tools and Computational Fluid Dynamics (CFD) programs are among the most widely used in industry for modeling physical behaviors.

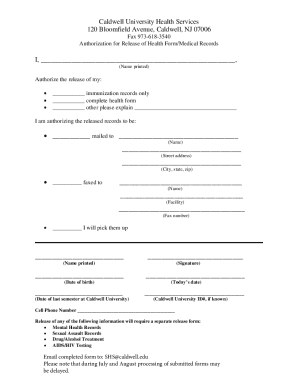

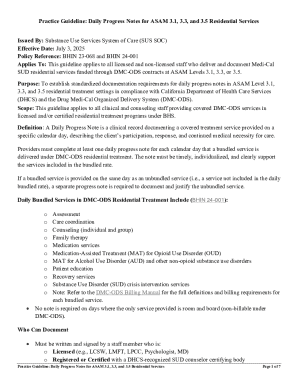

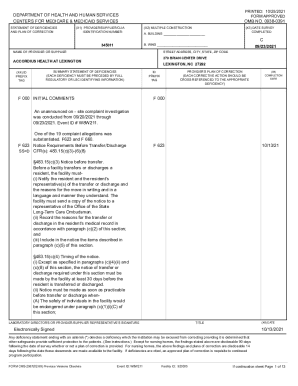

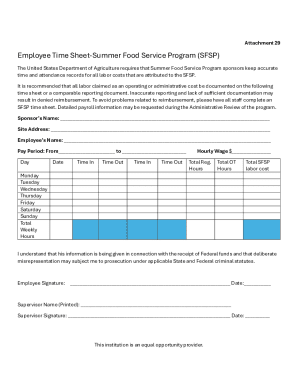

Using pdfFiller to manage document templates

In the realm of document creation for modeling reports, pdfFiller provides tailored templates designed specifically for the needs of microstructural parameter documentation. Users can easily edit and customize existing templates to match their specific requirements, ensuring that the final reports are not only accurate but also presentable.

Interactive tools

Features in pdfFiller promote collaboration and enhance the document workflow. Real-time editing and commenting functionalities make it easy for teams to provide feedback, ensuring a smooth process when refining models and documentation. This interactivity within workflows contributes to increasing overall productivity and clarity.

Case studies and practical applications

Examining successful models in various industries reveals how microstructural parameters can be effectively utilized. In the aerospace sector, the precision of grain structure modeling directly correlates with improved material strength, leading to lighter and more fuel-efficient structures. Similarly, in automotive applications, optimizing porosity and phase composition has enabled manufacturers to produce vehicles that are both safer and more efficient.

Lessons learned from case studies

These success stories yield valuable insights. Key takeaways include the importance of thorough testing and validation, which can prevent common pitfalls in modeling processes. Additionally, realizing the criticality of effective communication among team members ensures that insights from modeling are timely and actionable.

Integrating microstructural models into workflow

Integrating microstructural parameters into documentation involves structured reporting that effectively conveys complex materials data. It's essential to prioritize clarity and precision, especially when presenting data to stakeholders who may not be familiar with intricate technical details.

Collaborating with teams

Collaborative document management is enhanced through platforms like pdfFiller, which offers best practices for sharing and co-editing documents. This collaborative nature fosters innovation, as it allows teams to refine models and exchange constructive feedback, ultimately strengthening the modeling process.

Advanced techniques in modeling

The field of microstructural modeling is constantly evolving, with researchers developing more sophisticated techniques to address the challenges of modeling complex materials. Innovative approaches include machine learning algorithms that can predict material behavior based on vast datasets of microstructural information.

Customizing models for specific needs

Customization of microstructural parameters ensures that modeling accurately reflects the unique characteristics of the materials involved. This tailoring process often involves iterative refinement of parameters to enhance model accuracy and reliability, ensuring that predictions align closely with experimental results.

Troubleshooting and FAQs

In the process of modeling microstructural parameters, common issues can arise, such as discrepancies between experimental results and model predictions. Identifying these errors promptly is crucial for effective troubleshooting. This may involve revisiting data collection methods or adjusting model parameters based on new insights.

Frequently asked questions

Incorporating expertise and user experience, common queries include those surrounding optimal techniques for model validation and strategies for effective data visualization. Addressing these FAQs can empower individuals and teams to enhance their modeling efforts, facilitating better understanding and application of microstructural parameters.

Conclusion of insights

Modeling microstructural parameters is an essential aspect of materials science that has widespread implications across various industries. By leveraging platforms like pdfFiller for document management, teams can optimize their workflows and enhance communication around complex modeling tasks. This integration of microstructural modeling into practice not only promotes efficiency but also helps in producing high-quality, reliable research outputs.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute microstructural parameters for modelling online?

How do I fill out the microstructural parameters for modelling form on my smartphone?

How do I complete microstructural parameters for modelling on an iOS device?

What is microstructural parameters for modelling?

Who is required to file microstructural parameters for modelling?

How to fill out microstructural parameters for modelling?

What is the purpose of microstructural parameters for modelling?

What information must be reported on microstructural parameters for modelling?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.