Get the free Anomaly Detection in Inventory Management Using Machine Learning

Get, Create, Make and Sign anomaly detection in inventory

Editing anomaly detection in inventory online

Uncompromising security for your PDF editing and eSignature needs

How to fill out anomaly detection in inventory

How to fill out anomaly detection in inventory

Who needs anomaly detection in inventory?

Anomaly detection in inventory form: A comprehensive guide

Understanding anomaly detection in inventory

Anomaly detection involves identifying data points or patterns that deviate significantly from the expected behavior in a dataset. In inventory management, its importance cannot be overstated, as it helps businesses maintain accurate stock levels and prevent potential losses. Anomalies in inventory can include discrepancies in stock levels, unusual spikes in usage, or unexpected variations in supplier deliveries.

Common types of anomalies in inventory include overstocking, understocking, delivery delays, and unexpected demands. For instance, a sudden influx of orders during a holiday season could indicate an anomaly that requires swift action to ensure sufficient stock.

The role of inventory forms

Inventory forms are essential tools used in tracking stock levels, managing shipments, and documenting transactions. Their primary purpose is to streamline the inventory process, making it easier for teams to manage stock accurately. However, traditional inventory management often presents challenges such as manual data entry errors, lack of real-time updates, and inadequate data analysis capabilities.

Anomaly detection significantly enhances inventory form processes by allowing real-time monitoring and analysis of inventory data. By integrating automated anomaly detection methods, organizations can quickly identify discrepancies, streamline processes, and maintain optimal inventory levels.

Algorithms and techniques for anomaly detection

A variety of algorithms and techniques are employed for anomaly detection in inventory systems. Popular methods include statistical approaches, machine learning models, and rule-based systems. Statistical methods involve establishing a baseline for what is considered normal behavior and flagging any deviations from that norm.

Machine learning models, such as clustering and classification algorithms, can analyze large datasets to identify complex patterns of anomalies. Rule-based systems apply predefined conditions that trigger alerts for anomalies within the inventory data.

Choosing the right algorithm depends on the specific needs of the inventory system and the nature of anomalies encountered. Businesses should evaluate their data complexity and the types of anomalies they wish to detect.

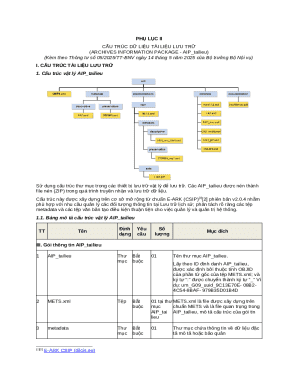

Preparing your data for anomaly detection

Before implementing an anomaly detection system, thorough data preparation is essential. This begins with data collection, ensuring that all necessary information such as stock levels, order history, and supplier data is gathered. The accuracy of this information is paramount, as inaccurate data can lead to misleading anomaly detection results.

Next, data cleaning is crucial for eliminating duplicates, correcting errors, and ensuring consistency. Structuring the data effectively enables the detection algorithms to analyze it more efficiently, allowing for accurate identification of anomalies.

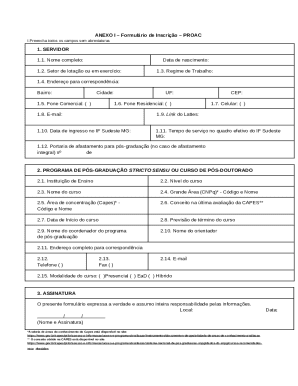

Setting up the inventory form for anomaly detection

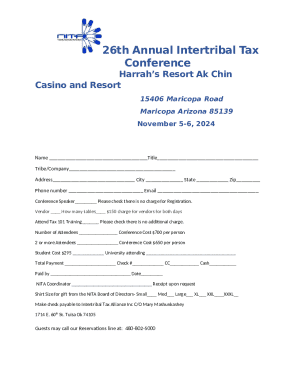

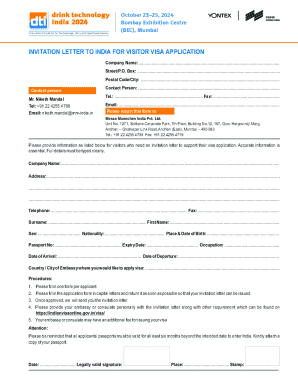

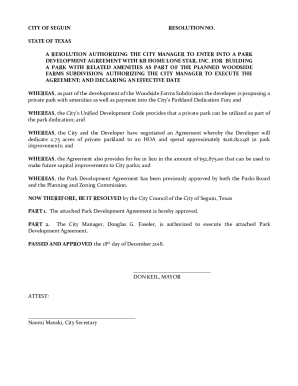

Designing an effective inventory form is crucial for capturing optimal data. The form should be user-friendly, ensuring that data entry is seamless and errors are minimized. Incorporating features such as dropdown menus, auto-fill options, and real-time validation can enhance data quality.

Interactive tools for template customization allow users to tailor forms according to their specific inventory needs. Additionally, integrating eSignatures and collaboration functionalities within the forms streamlines the overall inventory management process, making it easier for teams to work together efficiently.

Training the anomaly detection model

Training an anomaly detection model requires specific skills and tools, including knowledge of data science and machine learning frameworks. Organizations may choose to work with professionals in data science or leverage accessible tools designed for non-experts.

A step-by-step guide involves feeding cleaned and structured data into the model, selecting appropriate parameters, and initiating the training process. Periodically monitoring performance metrics allows for timely adjustments and improvements to the model, ensuring continued efficacy in detecting anomalies.

Detecting anomalies with your inventory form

Once your anomaly detection system is set up, key indicators of anomalies must be monitored closely. These can include drastic changes in stock levels, irregular ordering patterns, or sudden spikes in returns. Automating anomaly detection with alerts can provide immediate notifications when discrepancies arise.

Interactive tools can facilitate real-time detection demonstrations, showcasing how the anomaly detection system operates within your inventory form management. This proactive approach allows teams to address potential issues before they escalate, optimizing inventory management.

Visualizing anomalies and interpreting results

Visual representation of anomalies can significantly enhance understanding and facilitate decision-making. Methods such as scatter plots, heat maps, and dashboards can effectively visualize detected anomalies and their impact on overall inventory performance. Best practices for analyzing these results include seeking patterns and collaborating with cross-functional teams to address the root causes of anomalies.

Case studies showcasing successful implementations emphasize the importance of strong anomaly detection frameworks within inventory management. Organizations that have adopted these practices often report enhanced decision-making capabilities and improved efficiency.

Managing anomalies in inventory

Upon identifying anomalies, it's vital to implement strategies to address them promptly. This may include revising ordering processes, enhancing supplier communication, or updating inventory practices based on new insights derived from the anomaly detection process. Collaboration among teams is critical in resolving these issues effectively, fostering an environment of shared responsibility.

Regular data analysis and feedback loops ensure that inventory practices evolve continuously, adapting to the changing landscape of inventory needs and market demands.

Future trends in anomaly detection for inventory

Emerging technologies like artificial intelligence and augmented analytics are poised to influence anomaly detection significantly. These innovations facilitate more accurate predictions and insights, enhancing overall inventory management practices. Automation will play a critical role in streamlining processes and improving efficiency.

The evolution of inventory management demonstrates the growing reliance on data-driven strategies. Future predictions suggest that businesses adopting sophisticated anomaly detection systems will gain a competitive edge by making informed, timely decisions rooted in comprehensive data analysis.

Streamlining document management with pdfFiller

pdfFiller supports seamless inventory management by providing a user-friendly platform for creating, editing, and managing inventory forms. Its tools, including document editing and eSigning features, enable users to manage their documentation effectively, facilitating smooth workflows.

Collaboration and sharing capabilities allow teams to work together on inventory forms, enhancing communication and reducing the time spent on document management. By utilizing pdfFiller's resources, businesses can enhance their anomaly detection efforts and overall inventory management.

Conclusion of anomaly detection in inventory form

Anomaly detection is a critical component of effective inventory management. It empowers organizations to maintain accurate stock levels, prevent losses, and make informed decisions based on real-time data. The adoption of innovative inventory solutions can greatly enhance operational efficiency.

As businesses increasingly shift towards data-driven strategies, the importance of anomaly detection in inventory forms will continue to grow. Embracing these advancements is essential for organizations striving for transparency and accuracy in inventory management.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify anomaly detection in inventory without leaving Google Drive?

How can I send anomaly detection in inventory for eSignature?

How do I edit anomaly detection in inventory on an Android device?

What is anomaly detection in inventory?

Who is required to file anomaly detection in inventory?

How to fill out anomaly detection in inventory?

What is the purpose of anomaly detection in inventory?

What information must be reported on anomaly detection in inventory?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.