Get the free FIBER OPTIC & DRY UTILITY

Get, Create, Make and Sign fiber optic amp dry

How to edit fiber optic amp dry online

Uncompromising security for your PDF editing and eSignature needs

How to fill out fiber optic amp dry

How to fill out fiber optic amp dry

Who needs fiber optic amp dry?

Fiber Optic Amp Dry Form: A Comprehensive Guide

Understanding fiber optic amplifiers

Fiber optic amplifiers are crucial components in modern telecommunications, serving to boost the strength of optical signals transmitted through fiber optic cables. By amplifying these signals without the need to convert them into electrical form, these devices help maintain the integrity and speed of data transmission over long distances. The amplification process is vital for reducing loss and enhancing the overall performance of communication systems.

The importance of dry forms in fiber optic amplification is often overlooked. Dry forms refer to the specific configuration and preparation methods used in the fabrication and deployment of fiber optic amplifiers, ensuring optimal performance, reliability, and durability. Essential components typically include doped fibers—such as erbium-doped fibers—specialty fibers for unique applications, photonic crystal fibers that manipulate light more efficiently, and a meticulous drawing process that connects the manufacturing of the fiber preform to the final product.

Applications of fiber optic amplifiers

Fiber optic amplifiers have transformed numerous sectors by enhancing signal transmission capabilities. In telecommunications, they are pivotal for ensuring that voice and data signals travel over extensive networks with minimal degradation. By amplifying these signals, providers maintain high-speed data pathways, accommodating the growing demands of internet bandwidth.

Data centers rely heavily on fiber optic amplification to manage and deliver vast volumes of data efficiently. With increasing reliance on cloud computing and big data analytics, the integrity of data transfer must remain uncompromised. Moreover, broadcasting networks employ these amplifiers to ensure that television and radio signals are transmitted clearly, enhancing viewers' and listeners' experiences. In military and aerospace applications, where secure communications are critical, fiber optic amplifiers facilitate reliable, high-bandwidth connections under challenging conditions.

Types of fiber optic amplifiers

Various types of fiber optic amplifiers cater to different needs and applications. Erbium-Doped Fiber Amplifiers (EDFAs) are among the most widely used due to their high gain over long wavelengths relevant to optical communications. The principles behind EDFAs involve the doping of fibers with erbium ions, allowing them to efficiently amplify optical signals. A unique advantage of EDFAs is their compatibility with existing fiber optic infrastructure, making them a popular choice for service providers.

Semiconductor optical amplifiers (SOAs) utilize semiconductor materials to provide a compact solution for signal amplification. These amplifiers are revered for their versatility and capability to integrate with electronic circuits. Raman amplifiers, on the other hand, work differently; they employ the principles of stimulated Raman scattering, allowing for high gain and noise performance. They are particularly useful in long-haul communication systems. Each type has its unique advantages, making it crucial to select the right amplifier based on specific requirements.

The importance of dry forms in fiber optic amplification

In the context of fiber optic amplification, dry forms refer to the engineering specifications and configurations that enable amplifiers to function seamlessly in various environments. Using the right dry form is essential in ensuring the durability, reliability, and performance of fiber optic amplifiers. The benefits of utilizing dry forms include improved signal integrity, lower installation costs, and enhanced operational longevity.

The distinction between wet and dry forms in amplification is also critical. Wet forms involve the use of liquid or gel solutions for doping, which can lead to inconsistencies in performance and reliability. In contrast, dry forms, such as those realized through sophisticated glass fabrication techniques like modified chemical vapor deposition (MCVD), provide consistency and a higher quality of fiber preforms. This precision ultimately leads to superior optical properties and lower attenuation, a pivotal factor in long-distance data transmission.

How to fill out the fiber optic amp dry form

Filling out the fiber optic amp dry form accurately is essential to ensure that all specifications align with operational needs. Start by gathering necessary information, such as wavelength and power requirements, since these specifications are fundamental to the overall performance of the fiber optic amplifier. Each detail matters, making it crucial to cross-check and validate your inputs against industry standards.

When completing the template, guidance on specific sections helps ensure that crucial technical details are accurately captured. Pay attention to best practices for accuracy, particularly in the technical details section. Optional fields can be included as needed, reflecting any additional specifications or operational parameters beneficial for end-users.

Editing and collaborating on the fiber optic amp dry form

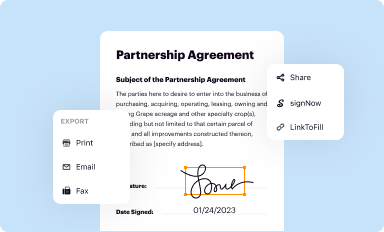

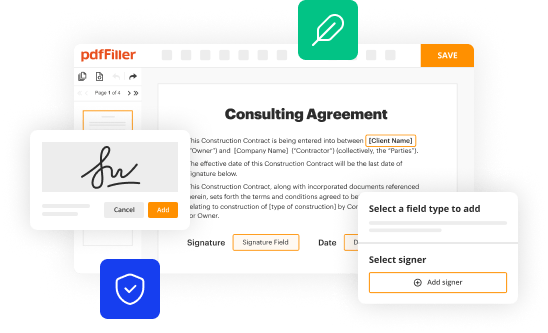

Utilizing tools such as pdfFiller enhances the editing process of PDF forms like the fiber optic amp dry form. Users can add text, images, and signatures seamlessly. This flexibility not only ensures accuracy but also allows for a polished presentation of the final document. The collaboration features within pdfFiller further streamline the review process, enabling team members to share the document easily, provide comments, and make revisions in real-time, thus improving workflow efficiency.

Employing the commenting functions fosters teamwork and ensures that all stakeholders can contribute insights and improvements. This collaborative process is vital, particularly when multiple experts contribute different perspectives on different aspects of the fiber optic amp dry form, allowing for a comprehensive final product.

Managing your completed fiber optic amp dry form

Once the fiber optic amp dry form is filled out and reviewed, managing the document efficiently is critical. Users have the option to save completed forms in the cloud or download them locally, providing flexibility depending on organizational needs. Cloud storage ensures that users can access their documents from anywhere, promoting operational efficiency.

For added security and legal validity, e-signing the document is recommended. This step ensures that the completed dry form is binding and meet legal standards. Additionally, incorporating tracking and version control procedures aids in keeping records organized, allowing easy access to previous iterations of the document and maintaining an audit trail for accountability.

Troubleshooting common issues with fiber optic amp dry forms

Troubleshooting common issues with fiber optic amp dry forms is crucial for ensuring accuracy and efficiency. Incomplete forms can lead to delays in the production process, so it's essential to ensure that all necessary information is provided. Regularly reviewing forms against a checklist of required specifications can minimize these problems.

Technical errors such as incorrect data entries or incompatible formats can also create issues. When faced with technical errors, consulting support resources or user manuals can provide quick solutions. Additionally, utilizing pdfFiller's support features ensures that users have access to necessary assistance when discrepancies occur, thus relieving stress during the documentation process.

User feedback and community insights

Engaging with user feedback fosters a community around fiber optic amplifiers and their implementation. Common questions often relate to the nuances of different fiber optic amplifier types and how they affect performance. By sharing experiences and outcomes, users can gain insights into best practices for utilizing the fiber optic amp dry form effectively.

Users are encouraged to share their thoughts on how the form has improved their workflow or provided solutions to specific challenges. Tips from experienced users often highlight features of the pdfFiller platform that maximize efficiency, such as utilizing templates for repetitive entries and maintaining thorough documentation practices.

Future trends in fiber optic amplification

As technology evolves, so do fiber optic amplification methodologies, with several trends on the horizon. One significant innovation involves advancements in fiber fabrication techniques, such as 3D printing preforms, paving the way for quicker and more efficient amplifier designs. Employees involved in fabrication and deployment must adapt continuously to these innovations to remain competitive.

The impact of advances in fiber optics also extends to documentation and form management. Cloud-based solutions like pdfFiller will continue to play a vital role in simplifying the administrative tasks associated with fiber optic amplifier management. Continuous learning and adaptation will be essential for professionals in the field to leverage these technological advancements to their full potential.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit fiber optic amp dry online?

How can I edit fiber optic amp dry on a smartphone?

How do I fill out fiber optic amp dry on an Android device?

What is fiber optic amp dry?

Who is required to file fiber optic amp dry?

How to fill out fiber optic amp dry?

What is the purpose of fiber optic amp dry?

What information must be reported on fiber optic amp dry?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.