Get the free Manlift Operator's Daily Inspection Report Rental Company

Get, Create, Make and Sign manlift operator039s daily inspection

How to edit manlift operator039s daily inspection online

Uncompromising security for your PDF editing and eSignature needs

How to fill out manlift operator039s daily inspection

How to fill out manlift operator039s daily inspection

Who needs manlift operator039s daily inspection?

Manlift operator039's daily inspection form: A comprehensive guide

Understanding the importance of daily inspections

Daily inspections of manlifts are crucial for ensuring the safety of both the operator and workers on the job site. Regular inspections help in identifying and rectifying potential hazards before they result in accidents or injuries. For many industries, these inspections are a legal requirement, with stringent regulations set forth by the Occupational Safety and Health Administration (OSHA). By adhering to these protocols, companies can reduce liability and promote a culture of safety.

Failing to conduct daily inspections can carry severe legal and operational implications. Companies may face fines, shutdowns, or even legal action if found negligent. Understanding OSHA regulations, along with local and state laws regarding equipment safety, can safeguard organizations from these potential risks.

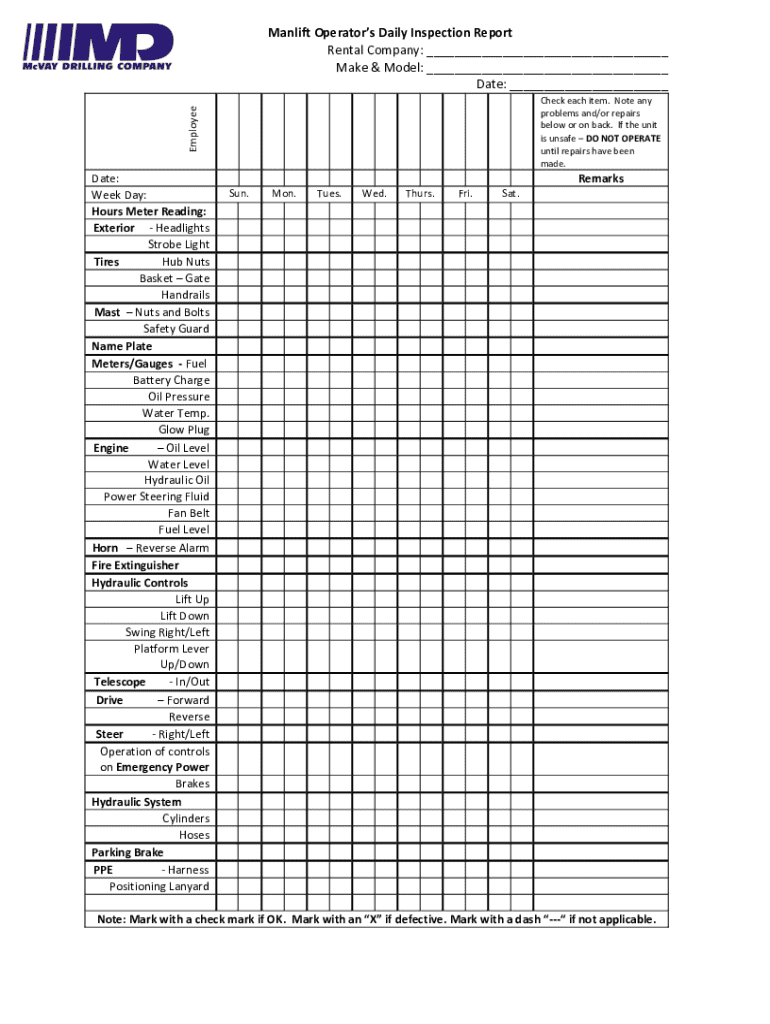

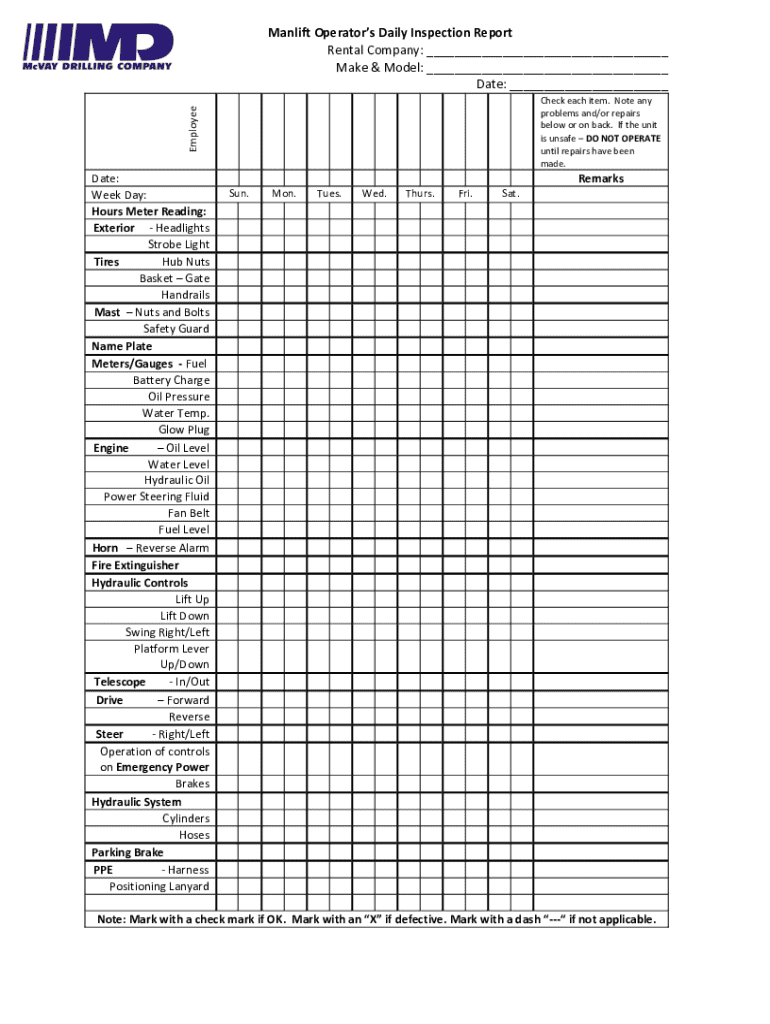

Overview of the manlift operator039's daily inspection form

The primary purpose of the manlift operator039's daily inspection form is to ensure operational compliance and streamline reporting processes. This form serves as a checklist for operators, guiding them through a thorough inspection of the manlift each day before use. By completing the form, operators document the condition of the equipment, which can aid in accountability and traceability.

Key components of the form typically include the following fields: date of inspection, operator name, equipment identification number, inspection results for various components (e.g., brakes, tires, safety devices), and areas needing attention or repair. Accurate data entry is essential; not only does it provide critical information for maintenance teams, but it also serves as a legal document in case of an incident.

Step-by-step guidance on completing the form

Preparing for the inspection involves gathering necessary tools, such as a flashlight, inspection mirror, and personal protective equipment (PPE). Operators should schedule inspection times to ensure equipment is ready for use by the start of the workday and that inspections are conducted in a consistent manner.

During the visual inspection, operators must check the structural integrity of the manlift, ensuring no cracks or damages are present. It is also important to examine safety features like guardrails and harness points. These checks help confirm that lifesaving features function properly.

Documenting findings is the next step, and operators should adhere to best practices when filling out the inspection form. Clarity in documenting inspection results is crucial for effective communication with maintenance teams and enhancing workplace safety.

If any issues are identified, operators must have procedures in place to report these faults effectively, including communication with the maintenance team to rectify the problem.

Utilizing pdfFiller for enhanced form management

pdfFiller transforms how organizations manage their manlift operator039's daily inspection forms. Users can easily upload their inspection forms to pdfFiller, allowing for seamless editing and customization. The platform's editing tools enable refinement of the forms, ensuring they meet specific operational needs.

Moreover, pdfFiller offers eSigning and collaboration features, making it easier for team members to review and sign off on inspections. The platform also tracks changes and maintains version control, simplifying the overview of document updates.

Another vital aspect of pdfFiller is its cloud-storage capabilities, allowing users to access their forms from anywhere at any time. The organization of documents ensures easy retrieval when needed, enhancing operational efficiency.

Best practices for manlift inspections

Routine maintenance is vital for prolonging the life of manlifts. Operators should regularly perform checks on equipment and schedule technician inspections in conjunction with daily checks. For instance, maintaining hydraulic fluid levels, checking for leaks, and ensuring all moving parts are properly lubricated can prevent more significant issues down the line.

Training for operators is equally essential. Continuous education on equipment usage, safety guidelines, and completing the manlift operator039's daily inspection form ensures that operators stay informed about the best practices and compliance requirements. Workshops and courses are valuable resources for enhancing operator skills.

Addressing common issues in daily inspections

Identifying common problems during inspections means operators can anticipate and address them proactively. Common faults might include malfunctioning safety devices, irregular maintenance signals, or visible damage to equipment. Establishing clear procedures for resolving these issues is critical.

In cases of unsafe conditions, operators must know the appropriate reporting procedures. This could include notifying supervisors immediately, filling out incident reports, and marking equipment as out of service until repairs are made, ensuring safety is prioritized at all times.

Leveraging technology to improve inspection efficiency

Adopting mobile solutions for real-time data entry can enhance the efficiency of inspections. Utilizing tools like pdfFiller allows operators to complete the manlift operator039's daily inspection form on mobile devices, eliminating delays in documentation and boosting accountability.

Integration with safety management systems can also streamline operations. This connection ensures that all safety reports and inspection forms, including the daily inspection form, are correlated, fostering a comprehensive understanding of overall safety performance.

Additional considerations for different work sites

Adapting the manlift operator039's daily inspection form for specific environments is critical. For instance, construction sites may have different operational hazards than industrial settings. Tailoring inspection criteria to address unique challenges ensures that all potential risks are identified and mitigated.

Incorporating feedback from operators and supervisors plays a crucial role in continuous improvement. By regularly reviewing and discussing the inspection forms, teams can enhance their safety protocols and create a more robust working environment.

Conclusion: Driving safety and compliance through effective documentation

Reinforcing the value of consistent inspections fosters a culture of safety within organizations. Regularly completing the manlift operator039's daily inspection form not only ensures compliance with legal standards but also empowers operators to take ownership of safety in their daily routines. Emphasizing thorough documentation helps create a safer workplace, ultimately benefiting everyone involved.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify manlift operator039s daily inspection without leaving Google Drive?

How can I send manlift operator039s daily inspection for eSignature?

How can I edit manlift operator039s daily inspection on a smartphone?

What is manlift operator's daily inspection?

Who is required to file manlift operator's daily inspection?

How to fill out manlift operator's daily inspection?

What is the purpose of manlift operator's daily inspection?

What information must be reported on manlift operator's daily inspection?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.