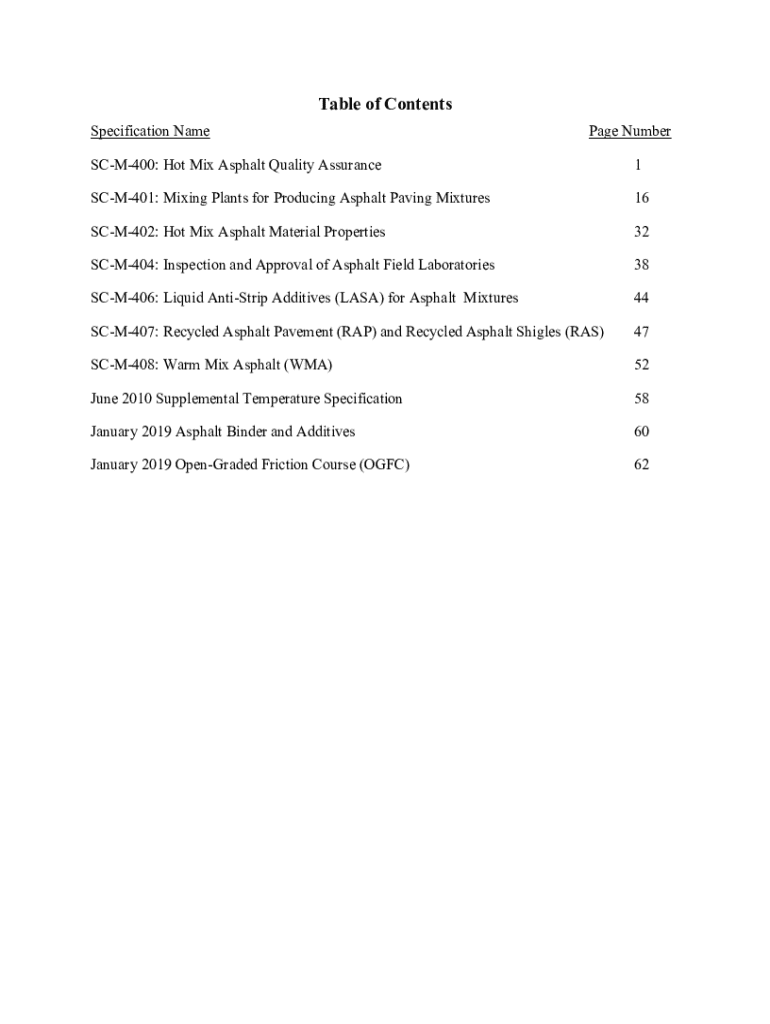

Get the free Mixing Plants for Producing Asphalt Paving Mixtures

Get, Create, Make and Sign mixing plants for producing

Editing mixing plants for producing online

Uncompromising security for your PDF editing and eSignature needs

How to fill out mixing plants for producing

How to fill out mixing plants for producing

Who needs mixing plants for producing?

Mixing plants for producing form: A comprehensive guide

Understanding the basics of mixing plants

Mixing plants play a crucial role in the production of forms, providing the necessary infrastructure for blending various materials into a uniform mixture. Whether it’s concrete for construction or other materials for manufacturing, understanding mixing plants is paramount for achieving quality and efficiency. They serve as the backbone of form production, ensuring that every element is integrated seamlessly before it reaches the final application.

The importance of mixing plants extends beyond just combining ingredients; they significantly impact the consistency and integrity of the final product. A well-managed mixing plant allows manufacturers to meet specific production demands and regulatory standards. Various types of mixing plants, including continuous and batch options, cater to different production needs, offering flexibility and specialization in material processing.

Key components of a mixing plant

The efficient operation of mixing plants hinges on a variety of essential machinery designed to perform specific tasks. Mixers, for instance, are the heart of any mixing plant, as they blend materials together to create a uniform mixture. Various types of mixers, such as paddle mixers and twin-shaft mixers, are engineered for different material properties and end-product specifications.

Conveyors and feeders play a critical role in transporting materials to and from the mixer. Using automated systems can greatly enhance the efficiency of material handling, reducing downtime and ensuring a continuous operation without interruptions. Additionally, material storage and handling systems are vital for maintaining inventory and providing consistent access to raw materials.

Quality control equipment is equally essential, as it ensures that the final product meets specific standards and specifications. Regular testing and monitoring help maintain the quality of the mixed product, preventing deviations that could compromise structural integrity.

Ingredients in form production

Producing high-quality forms requires a careful selection of ingredients. Aggregates, such as sand, gravel, or crushed stones, serve as the bulk material in many mixtures. Binders, including cement and adhesives, are critical in holding the aggregates together and providing the necessary strength to the final product. Each material plays a unique role in achieving desired properties such as durability, flexibility, and resistance to environmental factors.

Additives are often incorporated to enhance specific properties of the mixed material. For instance, plasticizers can improve workability and reduce water needs, while accelerators can expedite the curing process. Understanding the characteristics of each material is essential, as the quality of ingredients significantly influences the overall performance and longevity of the final forms.

The mixing process explained

The mixing process involves several stages, each critical for ensuring a homogeneous mixture. First, the preparation of ingredients entails measuring and transporting materials to the mixing area. Precision in this step is crucial, as discrepancies can lead to inconsistent product quality. Once the ingredients are set, the mixing equipment needs to be calibrated and ready for operation.

The next phase is executing the mixing cycle, where time and speed parameters play a vital role. The goal is to achieve a thorough blend within a specified duration, avoiding over-mixing or under-mixing, which can lead to compromised product integrity. Consistency in the mixing process is paramount; thus, regular monitoring and adjustments are necessary to maintain the desired quality throughout production.

Advanced techniques in mixing

Innovations in mixing technology have revolutionized the industry, introducing automated systems that enhance both efficiency and accuracy. Automated mixing systems allow for precise control over each phase of the mixing process, reducing the potential for human error. Additionally, real-time monitoring and analytics can provide invaluable insights into production efficiency, material usage, and process optimization.

Optimizing mixing efficiency also involves synchronizing components within the mixing plant. This synergy can drastically improve workflows, reducing delays and enhancing productivity. Utilizing collaboration tools can further streamline communications among teams involved in creating and executing mix designs, ensuring that everyone is on the same page and ready to make adjustments as needed.

Customizing your mixing process

Adjusting mix designs to cater to specific forms is both an art and a science. Trial and error approaches can sometimes work, but data-driven methods yield more reliable results. Establishing a robust research and development process helps manufacturers test various mix designs and ingredient combinations efficiently, allowing for rapid iteration and improvement.

Furthermore, harnessing the power of data-driven analytics can assist in identifying patterns and outcomes from previous mixing operations. By integrating such insights within the development workflow, companies can pave the way for innovative mixing solutions tailored to meet ever-evolving market demands.

Maintenance and troubleshooting

Regular maintenance practices are essential for the optimal operation of mixing plants. Keeping machinery in top condition not only prolongs its lifespan but also ensures that the mixing process operates smoothly. Maintenance routines should include routine inspections, cleaning, and timely repairs to minimize downtime and optimize productivity.

Common issues in mixing plants can range from equipment failures to inconsistencies in material mixing. Identifying these problems early and implementing solutions, such as recalibrating equipment or adjusting mix designs, is crucial for maintaining quality output. Safety protocols must also be prioritized in mixing plants, as ensuring a safe working environment protects workers and minimizes liability.

Leveraging cloud-based tools for mixing plants

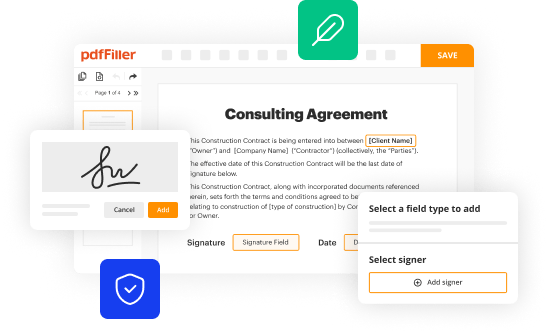

Implementing cloud-based platforms like pdfFiller can significantly enhance document management in mixing plants. Such tools streamline communication among teams, allowing for real-time updates on mix designs and documentation. This flexibility means that important documents are accessible from anywhere, facilitating better collaboration and speed in making adjustments as needed.

Integrating document management with mixing operations provides an efficient means of tracking changes and maintaining document histories. Capabilities like electronic signatures for approvals help ensure that every step in the mixing process is documented and verified, reinforcing accountability and accuracy in production.

Case studies: Successful mixing plant operations

Numerous examples illustrate the success of effective mixing plant implementations across various industries. One noteworthy case is a concrete mixing plant in California that integrated automated systems, resulting in a 30% increase in productivity while reducing waste by 15%. The company’s commitment to continuous improvement created a dynamic environment where feedback loops informed operational modifications.

Similarly, an asphalt mixing plant in Texas adopted advanced quality control measures, which not only improved product consistency but also enhanced overall production efficiency. These examples underscore the importance of understanding the unique needs of each operation and investing in the right technologies and processes to achieve exemplary results.

Future trends in mixing plants for producing forms

Looking ahead, mixing plants will likely witness significant advancements in technology, leading to increased efficiency and sustainability in operations. Innovations in material science are paving the way for eco-friendly materials, which are increasingly integrated within traditional mixing processes, supporting the global shift towards sustainable manufacturing practices.

Sustainability practices in mixing operations will not only enhance product appeal but will also align businesses with international standards and consumer demand for greener solutions. As the industry evolves, preparing your mixing plant for future challenges involves investing in both technology and training, ensuring that teams are equipped to adapt to new methodologies and practices seamlessly.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute mixing plants for producing online?

How can I edit mixing plants for producing on a smartphone?

How do I fill out mixing plants for producing on an Android device?

What is mixing plants for producing?

Who is required to file mixing plants for producing?

How to fill out mixing plants for producing?

What is the purpose of mixing plants for producing?

What information must be reported on mixing plants for producing?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.