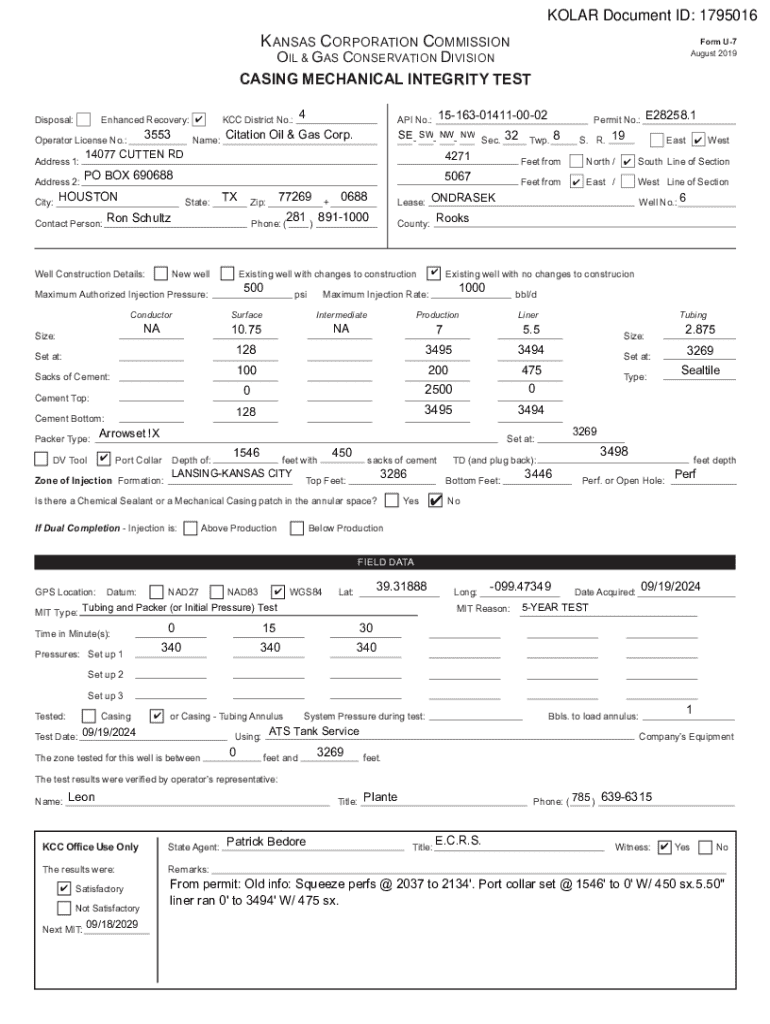

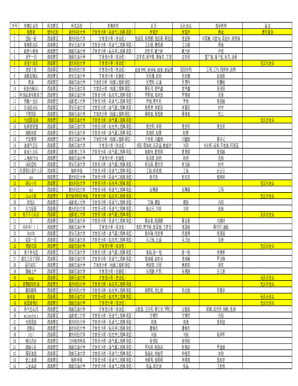

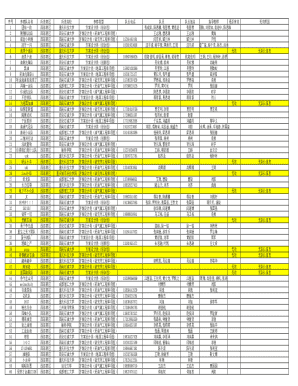

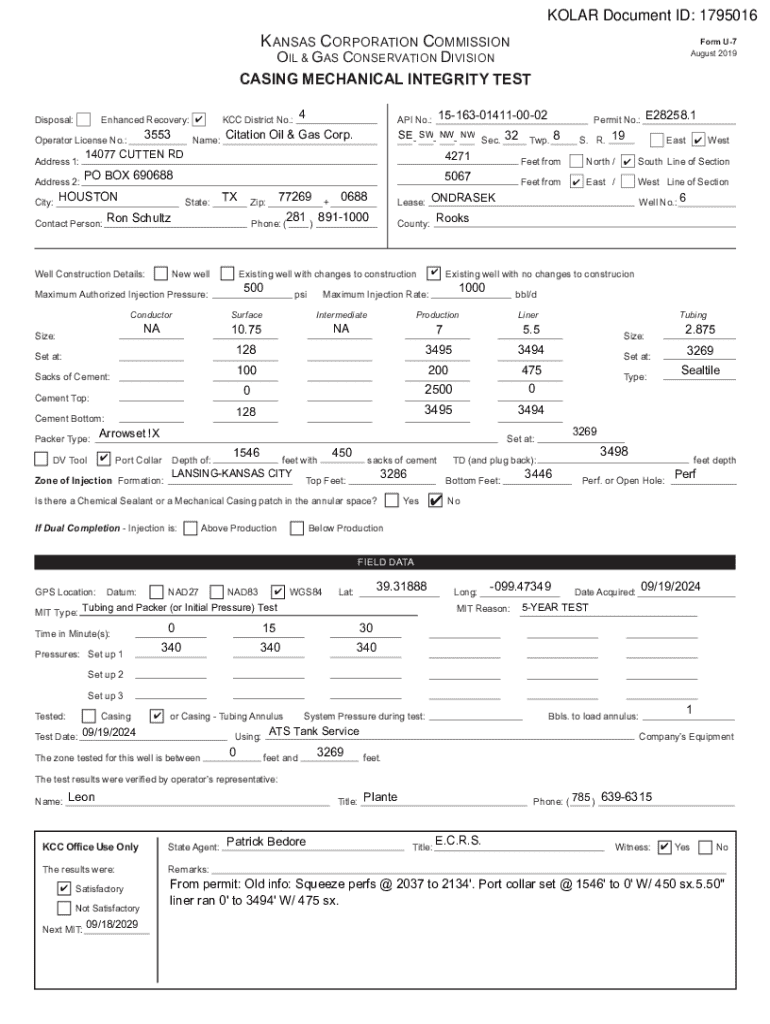

Get the free CASING MECHANICAL INTEGRITY TEST KOLAR Document ID

Get, Create, Make and Sign casing mechanical integrity test

How to edit casing mechanical integrity test online

Uncompromising security for your PDF editing and eSignature needs

How to fill out casing mechanical integrity test

How to fill out casing mechanical integrity test

Who needs casing mechanical integrity test?

A Comprehensive Guide to the Casing Mechanical Integrity Test Form

Overview of the casing mechanical integrity test

The casing mechanical integrity test (CMIT) is an essential evaluation tool used in the oil and gas industry to ensure the structural integrity of casings within wells. This test determines whether the casing is fit for its intended purpose and is capable of maintaining well safety and performance over time. As reservoirs mature and new technological advancements emerge, the importance of conducting regular casing integrity tests cannot be overstated. They not only help prevent environmental hazards and preserve valuable resources but also adhere to stringent regulatory requirements.

Casing integrity tests encompass various methodologies for evaluating the physical condition of well casings, such as pressure tests, ultrasonic testing, and other monitoring techniques. These tests aim to identify leaks or weaknesses that could compromise well integrity. Regulatory frameworks, including guidelines from agencies like the Environmental Protection Agency (EPA) and the American Petroleum Institute (API), dictate the standards and practices operators must follow to ensure compliance and safety.

Preparing for the mechanical integrity test

Preparation is key to successfully performing a casing mechanical integrity test. Operators should gather essential documents and information prior to testing, including casing specifications, historical performance data, and any previous rupture incidents. This information not only aids in understanding the current condition of the casing but also provides context for interpreting test results.

Additionally, effective scheduling is crucial. Considerations such as well location, accessibility, and environmental conditions can impact when tests are conducted. Establishing a timeline and coordinating with all relevant stakeholders ensures that the process runs smoothly. Safety measures must also be prioritized; operators should implement safety protocols that protect personnel and the environment, including ensuring the presence of emergency response teams and monitoring equipment for immediate action if needed.

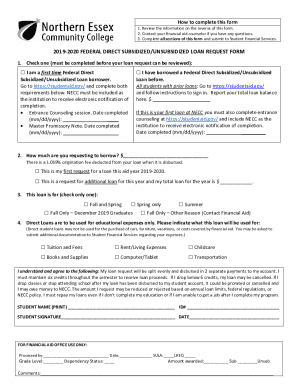

Step-by-step guide to filling out the casing mechanical integrity test form

Completing the casing mechanical integrity test form requires careful attention to detail and organization. This form generally consists of sections that gather relevant information, test parameters, and results to facilitate accurate records.

Interactive tools and resources for test preparation

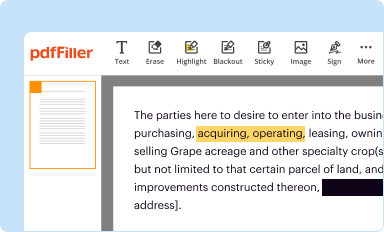

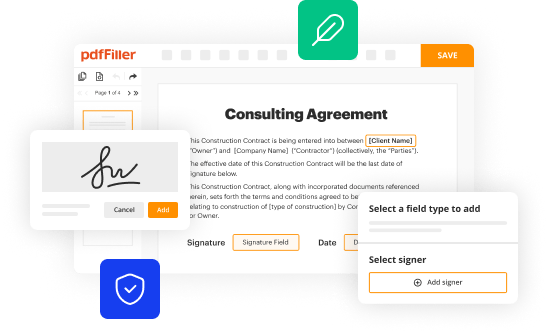

The use of digital tools has revolutionized how the casing mechanical integrity test form can be managed and filled out. Online platforms like pdfFiller offer interactive form-filling capabilities that streamline document management. Users can efficiently input data, making necessary edits, and store completed forms securely in the cloud, making them readily accessible from any location.

Templates are also critical resources available for users. A customizable casing mechanical integrity test form can facilitate consistency and accuracy across multiple tests. Alongside these templates, checklists ensure a thorough review of all requirements is completed before initiating the test, thus preemptively averting potential oversights.

Common issues during casing mechanical integrity tests

While performing casing mechanical integrity tests, operators may encounter a range of issues that can complicate the testing process. Potential test failures can arise from improper pressure application, equipment malfunction, or insufficient pre-test evaluations. Each of these issues not only disrupts the testing process but may also lead to costly remediation.

To troubleshoot these challenges effectively, operators should be equipped with comprehensive training that prepares them to handle unforeseen situations. For example, regular calibration and maintenance of testing equipment can significantly reduce the likelihood of mechanical failure during a test. Moreover, documenting any failures encountered during a test is essential for compliance and for informing future operational decisions.

Reviewing and submitting the test form

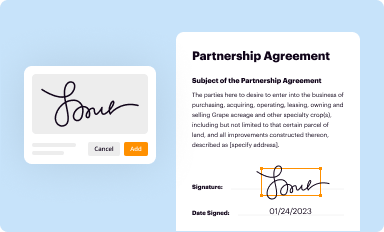

Once the casing mechanical integrity test form is completed, thorough review and validation of the entries are critical. Operators should ensure all sections are filled accurately and that the data complies with relevant regulatory standards. Utilizing digital tools, such as pdfFiller, provides additional features for e-signing and enabling stakeholders to review and approve forms quickly and efficiently.

The electronic submission process enhances efficiency and compliance. Many agencies now accept digital submissions, simplifying the overall workflow. Features like eSignatures facilitate quick approvals, while built-in compliance guidelines ensure that documents submitted meet necessary standards.

Post-test actions and follow-up

After the casing mechanical integrity test is concluded, the results must be carefully analyzed. This involves interpreting the data collected during the test and assessing what the results indicate about the condition of the casing. Operators should prepare to take necessary actions based on these results—whether it’s remediation, further monitoring, or transitioning to production, each decision should be grounded in the evidence provided by the test.

Documentation also plays a vital role in future operations. Maintaining a comprehensive record of test results helps create a knowledge base that can inform subsequent testing and overall well management. It’s essential to track these outcomes over time to identify trends and proactively address any potential issues before they escalate.

Collaborating with teams on test procedures

Casing mechanical integrity testing often requires collaboration across different teams and departments. Utilizing platforms like pdfFiller enhances this collaboration by allowing multiple stakeholders to access the document simultaneously. This capability streamlines the process, enabling teams to provide real-time feedback and updates directly within the form.

The access control and editing permissions functionality within pdfFiller ensure that team members can engage with the document according to their roles. This fosters effective communication and reduces the potential for errors during the documentation process due to miscommunication.

Accessing support and troubleshooting guidance

Given the complexity of the casing mechanical integrity testing process, access to reliable support is essential for resolving form-related issues. pdfFiller offers a dedicated support team ready to assist users with any challenges they may face while filling out and managing the test form.

Additionally, many users find it beneficial to refer to FAQs and community forums where common scenarios are discussed. This resource can be invaluable for troubleshooting and enhancing understanding, as users can learn from shared experiences and find quick solutions to similar problems.

Future trends in casing mechanical integrity testing

The landscape of casing mechanical integrity testing is continually evolving, with significant advancements on the horizon. Innovations in testing technologies, such as automated monitoring systems and real-time data analytics, promise to enhance the accuracy and efficiency of tests. These tools will allow operators to conduct more robust assessments and gain deeper insights into casing performance.

Moreover, digital solutions that integrate with existing operational workflows will become increasingly vital. Streamlined data collection and analysis, along with improved software for managing test documentation like pdfFiller, will empower operators to enhance their operational capabilities and ensure compliance in a rapidly changing industry.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I sign the casing mechanical integrity test electronically in Chrome?

How can I edit casing mechanical integrity test on a smartphone?

How do I edit casing mechanical integrity test on an Android device?

What is casing mechanical integrity test?

Who is required to file casing mechanical integrity test?

How to fill out casing mechanical integrity test?

What is the purpose of casing mechanical integrity test?

What information must be reported on casing mechanical integrity test?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.