HACCP Plan Template Form: A Comprehensive How-to Guide

Understanding HACCP: The importance of a structured approach

HACCP, which stands for Hazard Analysis Critical Control Point, is a systematic approach to food safety that focuses on identifying and managing potential hazards throughout the food production process. This method is crucial for both compliance with regulations and safeguarding public health. The implementation of a HACCP plan not only helps reduce the risk of foodborne illnesses but also enhances operational efficiency by pinpointing critical control points (CCPs) in the food production workflow.

Emphasizing quality and safety, HACCP plans are central to the food industry, ensuring consumer protection from pathogens and other physical, chemical, and biological hazards. Notably, the adoption of HACCP principles has been mandated by various food safety regulations worldwide, including the FDA in the United States and EFSA in Europe. Adopting these practices provides food businesses with a distinct competitive edge, instilling consumer trust and demonstrating a commitment to safety.

Improved consumer safety through systematic hazard analysis.

Enhanced compliance with local and international food safety regulations.

Increased efficiency in food production and processing.

Essential components of a HACCP plan

A well-structured HACCP plan is composed of key elements that work together to ensure food safety. Each of these components serves a distinct purpose, collectively providing a comprehensive approach to identifying, preventing, and controlling potential hazards in food processing. The primary parts of an effective HACCP plan include:

The overarching goal of the HACCP plan.

Defines the boundaries of the plan, including products and processes to be included.

Detailed information about the food products being processed.

Visual representation of the production process from start to finish.

Identification of potential hazards that could compromise food safety.

Specific points in the process where hazards can be controlled or eliminated.

Methods for tracking CCPs to ensure they remain within established limits.

Steps to be taken when monitoring indicates a deviation from an established limit.

Processes to confirm that the HACCP plan is functioning effectively.

Maintaining detailed records to demonstrate compliance and aid in audits.

Exploring the HACCP plan template form

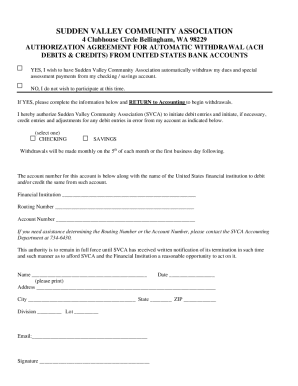

For those seeking to implement or refine their HACCP plans, the pdfFiller HACCP Plan Template Form offers an invaluable resource. This interactive template is designed to facilitate the exacting process of documenting a HACCP plan while enhancing overall user experience.

The visual layout of the template is intuitive, guiding users through each necessary section. The interactive features of pdfFiller allow for easy editing, signing, and sharing of documents, making collaboration more efficient. Users can fill the template out in real-time, ensuring that all team members are on the same page when it comes to food safety management.

Step-by-step guide to filling out your HACCP plan template

Filling out the HACCP Plan Template Form can seem daunting, but with careful preparation and organization, the process can be straightforward. Here’s a step-by-step guide to help you complete your HACCP plan.

Gather necessary information and resources, including employee input and product knowledge.

Fill out the objective and scope sections, clearly stating the purpose of your HACCP plan.

Describe the product and process in detail, ensuring that all relevant attributes are covered.

Develop a preliminary flow diagram outlining the various stages of the production process.

Identify potential hazards associated with each step of your food production process.

Determine your critical control points (CCPs) and why they are critical.

Outline monitoring procedures for each CCP, specifying methods and frequency.

Establish corrective actions to be taken when monitoring indicates deviation.

Implement record-keeping practices to maintain documentation and facilitate audits.

Collaboration is key in this process, especially when multiple team members are involved. Consider utilizing platforms like pdfFiller for real-time communication and document sharing, ensuring every relevant party can contribute to the HACCP plan effectively.

Interactive tools for managing your HACCP plan

Managing your HACCP plan doesn't just stop at filling out the template. The pdfFiller platform provides vital interactive tools that make ongoing management simple and efficient. Its cloud-based system supports real-time collaboration, which is essential for maintaining updated records and ensuring everyone on your team is aligned.

The platform also includes features for version control and document sharing, so you can track changes efficiently and ensure that all team members have access to the latest versions of your HACCP documentation. Furthermore, eSigning and approval features streamline the approval process, allowing you to manage consent and validate your compliance efforts directly within the platform.

Compliance and verification: ensuring your HACCP plan is effective

To ensure that your HACCP plan remains effective, regular audits and reviews are essential. Implementing a schedule for frequent assessments helps you identify areas needing improvement and ensures compliance with FDA and other relevant regulations.

Having a clear checklist can facilitate this verification process, ensuring all procedures are being followed properly. Ensure that your HACCP plan is regularly updated to reflect any changes in the production process, as shifts in procedures or ingredients can introduce new hazards that need to be addressed swiftly.

Real-world examples and best practices

Success stories from various food processing operations highlight the effectiveness of well-implemented HACCP plans. For instance, a dairy processing company reported a significant reduction in foodborne illness outbreaks after integrating a comprehensive HACCP framework into their operations.

However, challenges often arise in the form of information gaps, staff training issues, and procedural inconsistencies. Effective communication and training programs can alleviate these difficulties, alongside real-world examples illustrating how others overcame similar obstacles. Drawing insights from successful implementations can foster a culture of food safety.

Frequently asked questions (FAQs)

Common questions surrounding HACCP plans often center around development, integration, and execution. For instance, many wonder how to align HACCP principles with existing food safety management systems. The key is to ensure that all components of HACCP are compatible with you're already established practices while filling any identified gaps.

In addition, frequently addressing common concerns provides reassurance, helping organizations achieve a smoother transition to rigorous HACCP practices.

Next steps for implementation

Once you have filled out your HACCP plan using pdfFiller’s features, the next steps involve continuous improvement and adaptability. The landscape of food safety is ever-evolving, and staying informed about new techniques, regulations, and technologies is vital.

Engaging with resources and experts in the field can provide valuable insights that will allow you to fine-tune your HACCP approach. Being proactive with updates and adjustments ensures that your operations are always in line with best practices in food safety.

Contacting support for personalized assistance

pdfFiller offers robust support systems for users navigating document management challenges. Accessing personalized assistance can help new users maximize the platform's capabilities while enhancing overall efficiency in managing their HACCP plans.

Resources for additional training and development in HACCP principles can further empower teams, ensuring they are equipped with knowledge and best practices necessary to maintain safety standards in food processing.