Get the free VERIS Verabar Flow Sensors - Accurate Gas, Liquid & ...

Get, Create, Make and Sign veris verabar flow sensors

How to edit veris verabar flow sensors online

Uncompromising security for your PDF editing and eSignature needs

How to fill out veris verabar flow sensors

How to fill out veris verabar flow sensors

Who needs veris verabar flow sensors?

Veris Verabar Flow Sensors Form: A Comprehensive Guide

Overview of Veris Verabar Flow Sensors

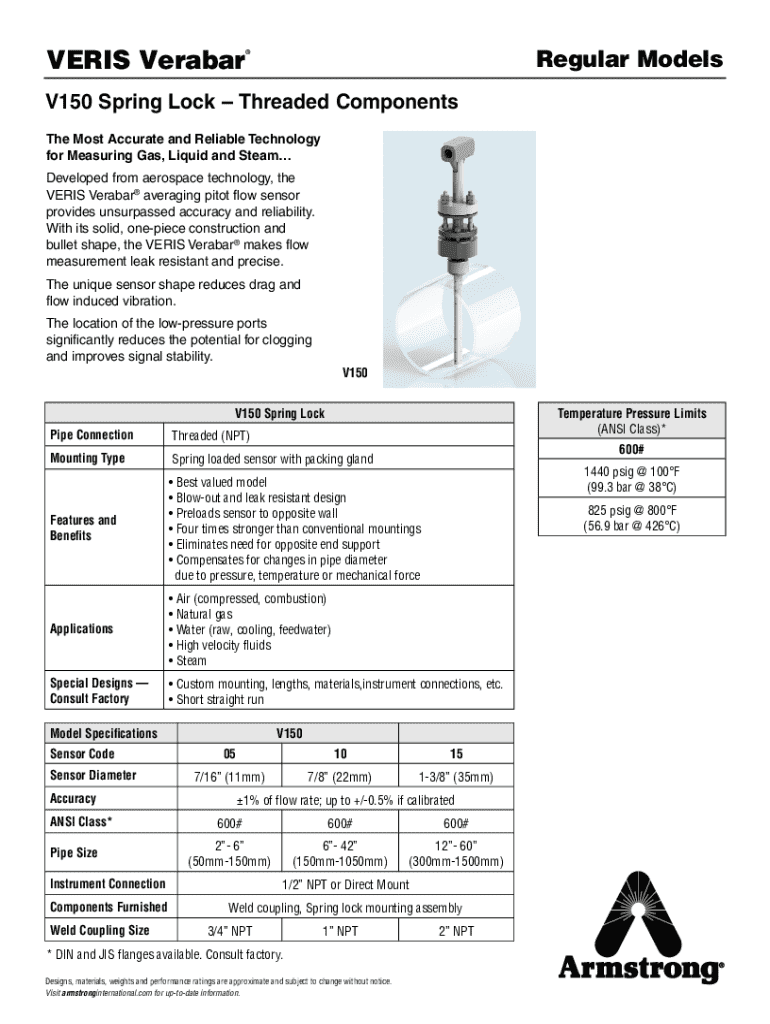

Veris Verabar Flow Sensors are high-performance instruments designed for precise flow measurement of gases, liquids, and steam across various industrial applications. Their unique design enables accurate sensing capabilities, making them essential in environments where flow rates are critical. Understanding these sensors is fundamental to optimizing system efficiency and ensuring safety.

These sensors are particularly important in modern applications, as industries continue to require more sophisticated monitoring systems. They provide real-time data that is necessary for effective decision-making in sectors like water treatment, HVAC, chemical processing, and food production. As such, Veris Verabar flow sensors play a crucial role in maintaining operational integrity.

Product specifications

The Veris Verabar flow sensors come with multiple technical specifications tailored to meet varying operational requirements. Dimensions and sizes vary, making them adaptable for different installation environments. Their materials are specifically chosen for compatibility with a wide range of fluids, ensuring they withstand corrosion and pressure fluctuations.

Accuracy is paramount when it comes to flow measurement. Veris provides flow sensors with measurement ranges that cater to low and high flow rates while greatly minimizing the chances of error and maximizing reliability. This precision is enhanced by rigorous calibration standards that each model adheres to.

How Veris Verabar Flow Sensors work

Understanding how Veris Verabar flow sensors operate is essential for effective application. They utilize sophisticated principles of operation that involve flow measurement mechanisms. Fluid passes through sensing ports located at both the front and rear of the sensor. This design reduces turbulence and enhances accuracy by allowing for an unhindered fluid path.

Integrated electronic components collect data on flow rates, analyzing signals derived from the dynamic effects of the fluid. This data is then processed to produce accurate flow measurements. Comprehending this mechanism informs proper installation and ensures optimal performance from the outset.

Features and benefits of Veris Verabar flow sensors

Veris Verabar flow sensors come equipped with several advanced features that offer significant advantages. Among these is their superior resistance to clogging—a feature designed to enhance operational efficiency. This design is achieved through configurations that ensure minimal accumulation of particles, thereby reducing maintenance needs and maximizing performance longevity.

Another crucial benefit is the verified accuracy of these sensors. Rigorous calibration both before and during operation ensures that flow readings remain consistent and reliable. This real-world accuracy is vital for applications where precise management of resources is necessary, as inaccurate readings can lead to significant operational inefficiencies.

Managing your Veris Verabar flow sensors

For optimal operation, regular maintenance practices of Veris Verabar flow sensors cannot be overstated. Establishing a maintenance schedule that includes inspection of connections, calibration checks, and sensor functionality helps in early identification of potential issues. An effective checklist is prudent for avoiding oversights that might compromise system integrity.

Moreover, recognizing signs of wear and tear is vital. Changes in flow readings, unusual sounds during operation, or visible corrosion are indicators that maintenance is necessary. Ignoring these signals can lead to failure in sensor functionality and increased operational costs.

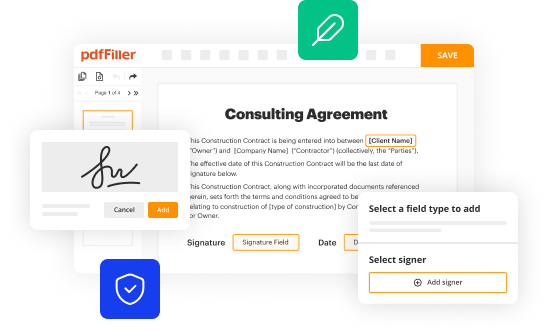

Interactive tools for form completion

Leveraging technology facilitates the management of documents associated with Veris Verabar flow sensors. pdfFiller, a cloud-based document management platform, empowers users to efficiently edit, eSign, and collaborate on forms related to flow sensors or other applications. This seamless experience ensures that all necessary documentation remains organized and easily accessible.

With pdfFiller, engaging in collaborative tasks becomes straightforward. Users can invite team members to contribute in real-time, fostering teamwork during form completion processes. Additionally, version control and document history features ensure that previous iterations of forms can be reviewed and reverted if needed, enhancing workflow efficiencies.

Compliance and certification

Veris Verabar flow sensors adhere to a variety of industry standards, ensuring their systems meet or exceed required benchmarks for reliability and precision. Compliance with these standards is crucial not only for legal adherence but also for maintaining the credibility essential in industries that rely heavily on flow measurement.

Certification processes play a significant role in guaranteeing that devices function within established parameters. Documentation relating to compliance helps users understand the level of reliability they can expect from their sensors.

User success stories and case studies

Examining real-world applications of Veris Verabar flow sensors illustrates their impact across various sectors. For instance, users in chemical processing environments have reported significant improvements in accuracy with real-time monitoring, leading to enhanced operational efficiencies. Positive feedback often emerges highlighting the reduction in maintenance costs due to advanced clog resistance.

Other noted benefits include increased yield in food processing plants where accurate flow measurements directly enhance product quality. Companies that have integrated these sensors see substantial returns on investment through minimized error rates and lower resource waste.

Frequently asked questions (FAQs)

Common queries regarding installation and operation of Veris Verabar flow sensors arise due to their complexity. Prospective users often wonder about the best practices for installation to ensure accurate readings. Techniques such as verifying flow direction and ensuring adequate clearance around sensor ports are critical for effective operation.

Other questions frequently pertain to troubleshooting the sensors. Understanding common problems, such as sensor misalignment or electrical signal disruptions, allows users to maintain optimal flow measurements. Documentation FAQs regarding forms and templates can also aid in ensuring that administrative tasks related to sensor management are effectively handled.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send veris verabar flow sensors for eSignature?

How do I make changes in veris verabar flow sensors?

How do I fill out veris verabar flow sensors using my mobile device?

What is veris verabar flow sensors?

Who is required to file veris verabar flow sensors?

How to fill out veris verabar flow sensors?

What is the purpose of veris verabar flow sensors?

What information must be reported on veris verabar flow sensors?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.