Get the free Blister with 2 film-coated tablets baloxavir marboxil 20 mg

Get, Create, Make and Sign blister with 2 film-coated

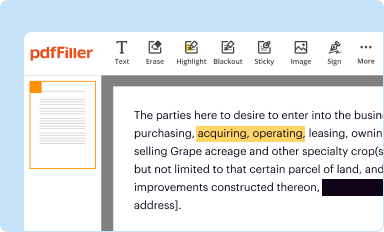

How to edit blister with 2 film-coated online

Uncompromising security for your PDF editing and eSignature needs

How to fill out blister with 2 film-coated

How to fill out blister with 2 film-coated

Who needs blister with 2 film-coated?

How-to Guide: Maximizing Efficiency with Blister with 2 Film-Coated Form

Understanding the blister with 2 film-coated form

A blister pack is a type of packaging widely used in the pharmaceutical, medical, and consumer goods industries to contain products securely. This form of packaging typically consists of a pre-formed plastic blister that houses individual doses of tablets, capsules, or other items. The '2 film-coated form' refers to an advanced blister pack design that emphasizes the use of two distinct film layers that provide enhanced protection and functionality. This construction improves the barrier against moisture and external elements, thereby prolonging product shelf life.

Film-coated forms are integral in several industries as they enable manufacturers to protect products from environmental conditions, preventing blistering and degradation. Products ranging from pharmaceuticals and nutraceuticals to electronics and consumer goods benefit significantly from this innovative packaging solution. They not only safeguard the product integrity but also enhance user experience by allowing for easy dispensing.

The advantages of implementing blister packaging solutions like the 2 film-coated form are manifold, including increased product stability, reduced contamination risks, and better compatibility with various filling processes. Importantly, this packaging form can significantly reduce waste and improve efficiency in production lines.

Types of film-coated forms in blisters

Film coatings play a pivotal role in the effectiveness of blister packaging. They can be classified into primary and secondary coatings, each serving unique purposes. Understanding these types allows manufacturers to tailor blister designs to meet specific product needs.

Primary film coatings are the first layer that interacts with the product. They often possess unique characteristics such as high moisture barrier properties and chemical resistance. Common materials used include polyvinyl chloride (PVC), polyethylene (PE), and various co-polymer blends that can be engineered to achieve desired vapor pressure and heat seal requirements.

Secondary film coatings further enhance the blister's performance. They may serve to provide additional physical protection, improve aesthetics, or include active ingredients that help to mitigate blister formation. Innovations in secondary formulations include anti-static agents and coatings that improve slip resistance.

Key steps in designing a blister with 2 film-coated form

Designing a blister with 2 film-coated forms begins with a thorough understanding of product requirements. Factors like the nature of the product (solid, liquid, or fragile), the intended shelf life, and regulatory requirements must be considered. Engaging in early-stage dialogue with product stakeholders ensures that their objectives are aligned with the design output.

Choosing appropriate materials is crucial for optimizing performance. Criteria for selecting primary and secondary coatings includes their compatibility with the product, moisture barrier capabilities, and overall durability. Testing these materials under expected storage conditions helps in identifying reliable options.

Once materials are selected, designing the blister layout involves usability considerations such as ease of access for consumers. Factors to consider include the size of the product, the number of doses per pack, and whether the blister design allows for clear labeling and branding.

Best practices for filling blister packs

Determining fill volume and configuration is critical for maintaining product consistency and safety. It’s essential to accurately gauge the volume that each cavity in the blister can accommodate. Proper fill volume impacts the efficiency of the filling process and helps to gauge material usage effectively.

Techniques for efficient filling processes can vary widely. Automatic filling systems are often preferred due to their speed and precision, significantly reducing human error. Manual filling methods can still be beneficial for small-scale operations, where flexibility and smaller batches are required.

Quality control measures in blister production

Adhering to quality standards is a mandated practice in the production of blister packs. This includes comprehensive evaluations that ensure the final product meets all safety and performance regulations. Quality control measures must be implemented at multiple stages of production, from raw material selection through the filling process.

Common tests and inspections encompass visual inspections for cosmetic defects as well as integrity testing to assess the effectiveness of film coatings. These inspections can identify issues like blister formation or salt contamination as early as possible, safeguarding product integrity.

Challenges in implementing blister with 2 film-coated form

Despite the numerous advantages, implementing blisters with 2 film-coated forms can pose challenges. One of the primary issues is ensuring compatibility of substances with film coatings, especially when dealing with volatile materials that could lead to blistering or bubbling due to vapor pressure differences.

Minimizing waste during production is another critical concern. Optimizing processes to balance fill accuracy with operational speed is essential. Additionally, navigating regulatory requirements regarding materials and production processes can be complex and requires staying abreast of changing standards.

Interactive tools for efficient document management

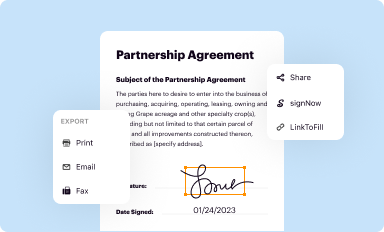

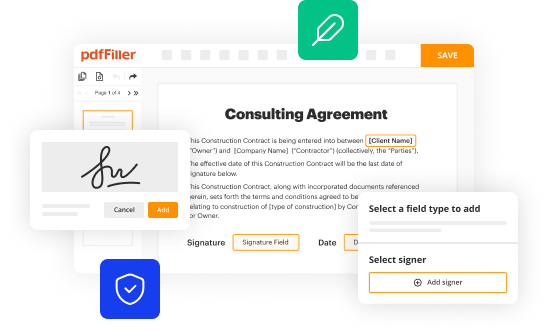

Utilizing pdfFiller for form filling and management streamlines the entire process tied to blister packaging. With robust editing capabilities, users can customize blister forms to reflect exact requirements. This precision is especially important in environments with stringent regulatory compliance.

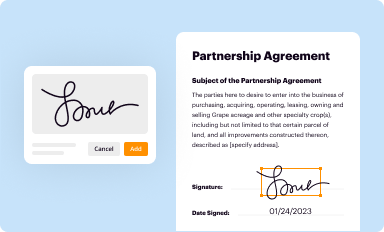

The platform also offers eSigning options, essential for validating processes and maintaining compliance. Collaborating effectively is crucial for teams, and pdfFiller supports managing multiple users and roles, ensuring that all stakeholders can contribute to document creation seamlessly.

Step-by-step process to create a customized blister form using pdfFiller

Accessing the pdfFiller platform to create a customized blister form is straightforward. Once logged in, users can choose from a plethora of templates tailored for blister packaging needs. This makes the initial stages of document creation not only quick but also user-friendly.

Adding and editing text fields specific to blister packs is simplified through intuitive tools that guide users. Once completed, sharing the document for final approvals is a mere click away, ensuring a seamless transition from design to production use.

Troubleshooting: common issues with blister packs

Handling blister failure scenarios requires a proactive approach. Common causes of defective packs often stem from unanticipated conditions such as temperature fluctuations that can affect material integrity, leading to issues like blister formation.

Solutions involve implementing rigorous testing protocols during production stages and adopting best practices that help prevent blistering and bubbling. For instance, controlling humidity and air presence during the sealing process can significantly improve outcome consistency.

Future trends in blister packaging technology

The future of blister packaging is poised for innovation. A key trend is the development of sustainable materials that not only reduce environmental impact but also maintain performance. Technologies that allow for the incorporation of smart features into blister packs are also on the horizon, enhancing user interaction and product information delivery.

Anticipated shifts in consumer preferences toward personalized packaging and stricter regulatory environments will require manufacturers to remain agile. Companies that embrace these changes will likely lead the market in blister packaging technology.

Leveraging cloud-based solutions for enhanced document management

Embracing cloud-based platforms like pdfFiller for managing documents associated with blister packaging offers numerous benefits. Such solutions allow teams to access necessary documents from anywhere, ensuring that projects remain agile and adaptable to changes in management or production demands.

Case studies illustrate how businesses have successfully implemented pdfFiller to streamline document workflows. Users report significant efficiencies gained through the platform’s collaboration features, enhancing team communication and effectiveness.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my blister with 2 film-coated in Gmail?

Where do I find blister with 2 film-coated?

How do I edit blister with 2 film-coated on an iOS device?

What is blister with 2 film-coated?

Who is required to file blister with 2 film-coated?

How to fill out blister with 2 film-coated?

What is the purpose of blister with 2 film-coated?

What information must be reported on blister with 2 film-coated?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.