Get the free Operations Specifications - Quality Inspections & Services, Inc.

Get, Create, Make and Sign operations specifications - quality

How to edit operations specifications - quality online

Uncompromising security for your PDF editing and eSignature needs

How to fill out operations specifications - quality

How to fill out operations specifications - quality

Who needs operations specifications - quality?

Operations specifications - quality form: A comprehensive guide

Understanding operations specifications

Operations specifications are detailed documents that outline the requirements and standards for an organization’s operations, particularly in regulated industries like aviation and manufacturing. They serve as a formal declaration of the procedures, limits, and operational practices that must be adhered to, ensuring consistency and compliance with regulatory standards.

The importance of operations specifications cannot be overstated. They function as critical tools for document management and compliance. These specifications align operational activities with quality assurance processes, reducing the risk of errors and enhancing safety protocols across various sectors. In industries subject to stringent regulations, such as the United States government and aviation, maintaining accurate operations specifications is not just best practice; it is mandated.

Key elements of operations specifications

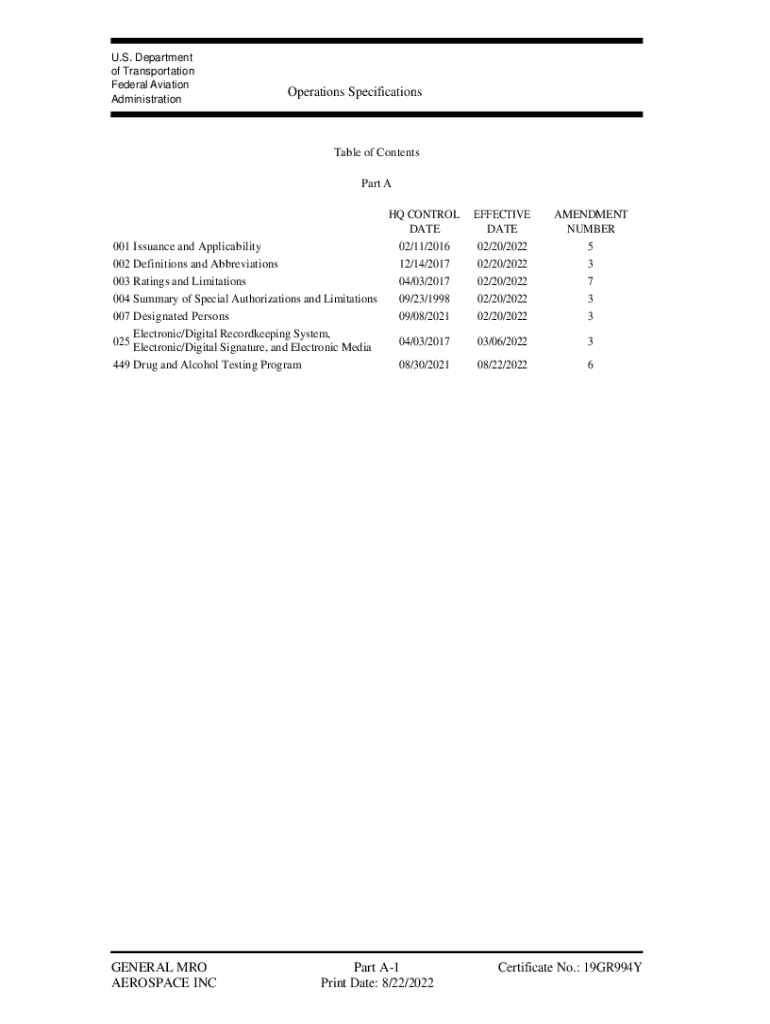

Detailed operations specifications are divided into clearly defined sections that cover everything from general overviews to advanced operational parameters. Section A consists of A001 to A013, outlining the essential guidelines for various operating scenarios. Each section must be thoroughly documented to provide clarity and direction, thus ensuring seamless operational flow.

Advanced operations specifications, which include sections B002 to B004, delve into more complex aspects of operations. These sections address crucial elements such as safety protocols, emergency procedures, and compliance requirements. Understanding these segments is vital, as they directly impact an organization's operational safety and efficiency. Therefore, every specification must be developed with precision to prevent misinterpretations and subsequent operational failures.

Navigating through operations specifications

Accessing and understanding your operations specifications is essential for effective implementation. For individuals and teams utilizing the pdfFiller platform, the process begins with familiarizing themselves with the document structure and contents. It is important to utilize secondary navigation tools to improve efficiency in operations and ensure adherence to the specifications outlined.

For instance, when considering aircraft navigation, specifications for Aircraft 1 must be meticulously reviewed and compared against operational requirements of Aircraft 2. Such comparisons ensure compliance with safety standards and operational guidelines. Similarly, air traffic navigation also entails procedures that must be followed to ensure both compliance and the efficient management of airspace, enhancing safety and operational cohesion.

Crafting your operations specifications document

Creating a quality operations specifications form involves several key steps. First, it is vital to define the scope of your operations, detailing what areas of activity the specifications will cover. This step ensures that all operational aspects are thoroughly considered and documented.

Next, identifying regulatory requirements is crucial, especially in regulated industries. These requirements will act as a guiding framework during the drafting process. When drafting sections A and B, it's important to maintain clarity and precision, as misunderstandings can lead to compliance issues and operational inefficiencies.

Leveraging digital tools for operations specifications

The pdfFiller platform revolutionizes the way organizations manage their operations specifications. With interactive tools designed for efficient document creation, pdfFiller enhances user experience by allowing easy modification of PDF forms. The editing capabilities offered ensure that users can update specifications promptly, which is essential in maintaining compliance amid changing regulations.

Moreover, eSigning features provide instant approval capabilities, eliminating the delays often associated with manual signature processes. Real-time collaboration with team members becomes a straightforward affair, making it possible to gather feedback and make revisions on the go. Such digital enhancements streamline the process and uphold the quality and accuracy of operations specifications, vital for organizational efficiency.

Case studies: Effective use of operations specifications

The implementation of robust operations specifications has yielded positive outcomes across various industries. For example, in the aviation sector, airlines that meticulously adhere to operational specifications experienced fewer safety incidents, demonstrating a direct link between quality documentation and operational success. Similarly, manufacturers who used comprehensive specifications reduced production errors, enhancing product quality and customer satisfaction.

Lessons learned from these case studies emphasize the critical nature of maintaining up-to-date and clearly defined operations specifications. Effective quality forms not only enhance operational efficiency but also contribute significantly to safety and regulatory compliance, ultimately leading to improved organizational performance.

Frequently asked questions

Maintaining clarity in operations specifications is crucial. Common queries often arise, such as how to properly access and navigate these documents. Users may also seek guidance on troubleshooting specific issues that arise during document management.

To address these queries, it is advisable first to consult the provided guidelines that accompany the specifications. Should problems persist, reaching out to support channels or utilizing forums can provide further assistance. Ensuring that all team members are adequately trained on document management can mitigate many common issues.

Best practices for maintaining operations specifications

Regular reviews and updates to operations specifications are essential for ensuring ongoing compliance and effectiveness. It is important to establish a routine review schedule, allowing for the incorporation of any new regulatory requirements and operational changes. Training teams on the current specifications further ensures that everyone is aligned with the standards and expectations.

Strategies such as implementing checklists for daily operations or utilizing digital platforms like pdfFiller for tracking changes can enhance your organization’s agility in adapting to regulatory changes. Emphasizing the importance of these specifications during training sessions encourages a culture of compliance and quality across the organization.

Understanding regulatory implications

Operations specifications must align with various regulatory requirements that govern different industries. These regulations often impact quality control and assurance protocols, necessitating thorough understanding and documentation in operations specifications. Failure to comply with these regulations can have severe consequences, including fines, operational suspensions, or even legal action.

To avoid non-compliance, organizations must stay informed about changes in regulations relevant to their operations. Engaging with industry standards and governmental resources will ensure your operations specifications remain robust, compliant, and up-to-date.

Resources for further information

For further exploration into operations specifications, various tools and platforms can assist in specification management. Suggested resources include government organizations that provide insights and updates on industry regulations. Engaging with leaders in your industry can also yield beneficial information and networking opportunities that support continuous improvement in operations specifications.

Reading materials on quality assurance, regulatory compliance, and operational efficiency can deepen understanding and enhance practical applications within your organization, solidifying the importance of quality form management in operations specifications.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for the operations specifications - quality in Chrome?

Can I create an eSignature for the operations specifications - quality in Gmail?

How do I fill out operations specifications - quality using my mobile device?

What is operations specifications - quality?

Who is required to file operations specifications - quality?

How to fill out operations specifications - quality?

What is the purpose of operations specifications - quality?

What information must be reported on operations specifications - quality?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.