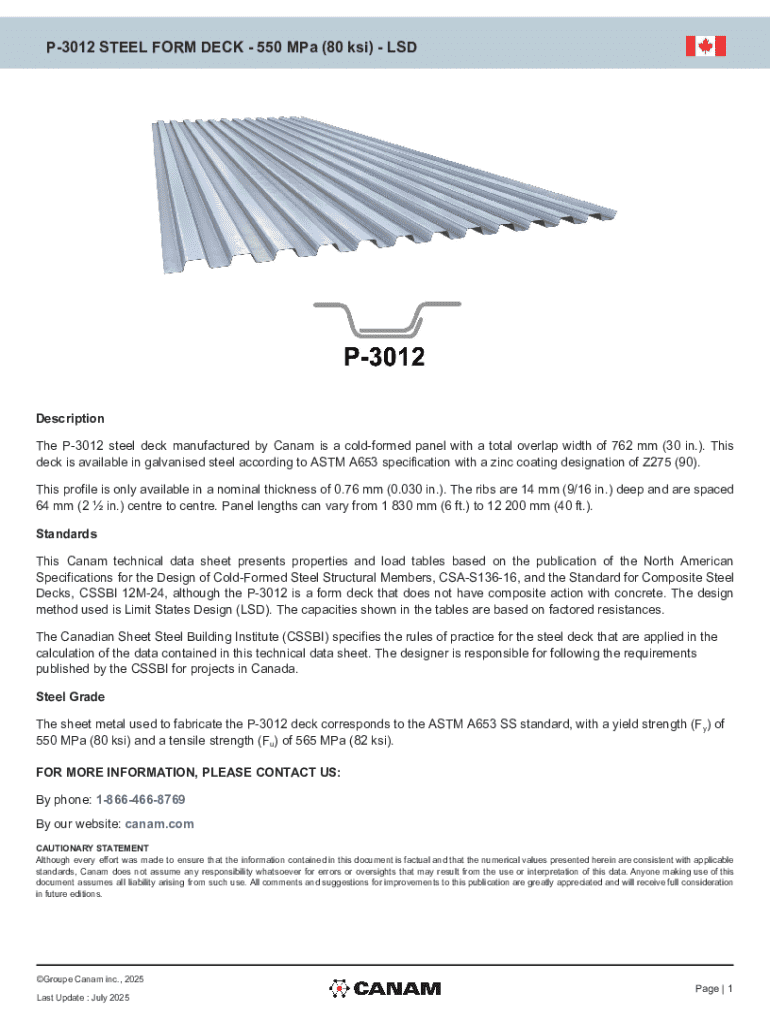

Get the free P-3012 Steel Form Deck - 80 ksi - LSD (Canada) - Canam. The P-3012 steel deck manufa...

Get, Create, Make and Sign p-3012 steel form deck

How to edit p-3012 steel form deck online

Uncompromising security for your PDF editing and eSignature needs

How to fill out p-3012 steel form deck

How to fill out p-3012 steel form deck

Who needs p-3012 steel form deck?

Comprehensive Guide to p-3012 Steel Form Deck Forms

Understanding p-3012 steel form decks

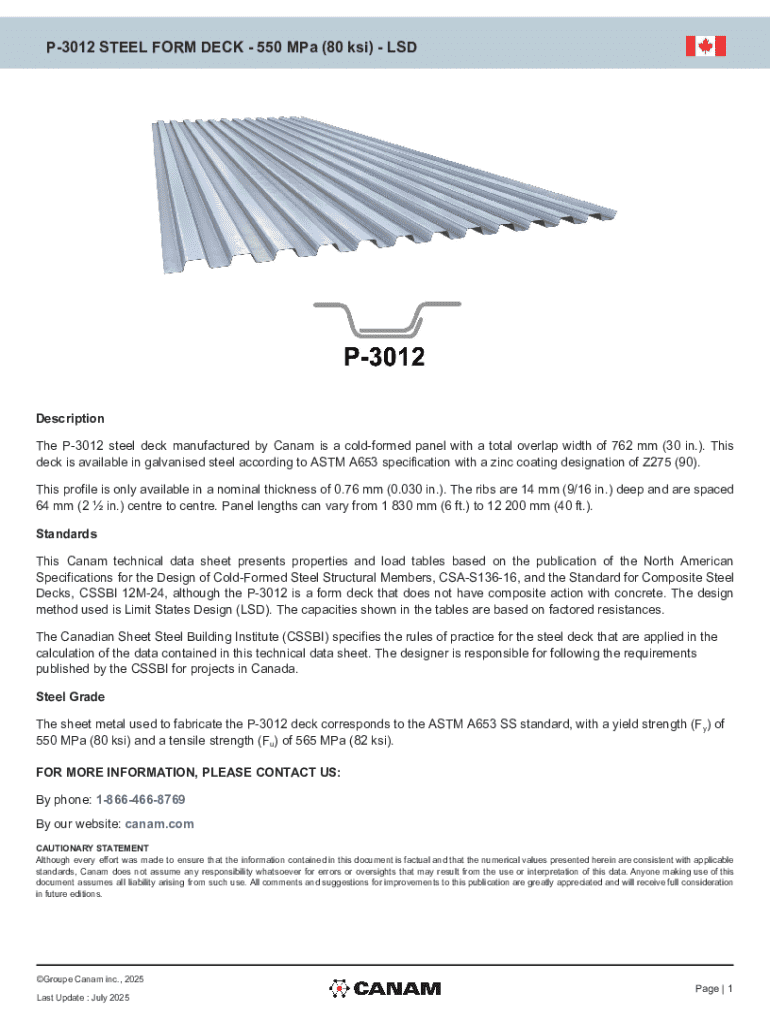

The p-3012 steel form deck is a crucial component used in commercial and industrial construction. Characterized by its ribbed design and high strength-to-weight ratio, it serves as both a structural and a permanent formwork solution. This type of deck facilitates the pouring of concrete, providing a solid foundation for floors and roofs, particularly in locations requiring robust load-bearing capabilities.

Applications of the p-3012 steel form deck are diverse, ranging from warehouses and retail spaces to multi-story buildings. Its versatility allows architects and engineers to employ it in various design configurations, ensuring it meets both aesthetic and functional demands.

Additionally, construction professionals value the p-3012 due to its ability to support heavy loads while providing a lightweight alternative to other decking options. This combination of properties makes it a preferred choice for modern construction projects across many locations, especially in Florida (FL) where climate resilience is essential.

Benefits of using p-3012 steel form decks

The adoption of p-3012 steel form decks offers several benefits, the most significant of which include durability and strength. The high-quality steel used in these decks ensures they withstand harsh weather conditions and regular wear, making them perfect for long-term use in structures built to last. Their innate resistance to rust and corrosion further enhances their longevity.

Cost-efficiency is another notable advantage. By combining structural support and formwork functions, the p-3012 eliminates the need for additional materials often associated with traditional concrete pouring methods. This integrated approach not only saves money but also reduces labor costs and overall project timelines.

The versatility in design provided by p-3012 form decks enables architects to think creatively about their projects. Whether it’s achieving unique architectural aesthetics or maximizing usable space, these decks adapt well to various design needs, ensuring that your construction project meets both practical and creative requirements.

Essential tools and materials

To work effectively with p-3012 steel form decks, specific tools are essential. Cutting tools such as shears or saws designed for metal work are critical for accurately sizing the steel forms. Additionally, joining equipment like welders and fasteners are necessary for ensuring a secure connection that can support the deck's integrity and load-bearing capacity.

In terms of materials, understanding specifications is key. The gauge and thickness of the steel used in p-3012 decks should meet local building codes and project requirements. Moreover, pre-coating options can offer improved weather resistance, crucial for projects located in areas prone to moisture or corrosive environments such as coastal regions in Florida.

Preparing for installation

Before installation, site assessment and preparation are critical steps. Evaluating ground conditions ensures that the soil can support the intended load of the structure, while proper support structures must be established to prevent any future issues. This includes ensuring that the underlying beams or supports are adequately positioned and ready for the weight of the p-3012 form deck and the concrete that will later be poured.

Designing the layout of your p-3012 installation involves careful measuring and marking. Accurate dimensions should align with site plans that comply with local building codes. This forethought can mitigate many challenges that could arise during or after the installation process. Always refer to architectural designs to ensure compliance and facilitate a smoother installation experience.

Installation process of p-3012 steel form decks

A successful installation of p-3012 steel form decks typically follows a step-by-step process. First, cutting the steel forms to the required size is essential for proper fitting. Next, position the forms onto the prepared supports, ensuring that they align according to the layout plan. Securing the forms with fasteners is crucial for maintaining their integrity during the concrete pour.

Ensuring proper alignment and leveling is a vital finalizing step before the concrete is poured. Common challenges during the installation might include uneven surfaces that could lead to misalignment. Employing techniques for overlapping panels can help mitigate these issues during the setup process.

Post-installation practices

Once installation is complete, conducting thorough inspections is necessary to confirm structural integrity. This process involves checking for defects or misalignments that could lead to significant problems in the future. Addressing potential issues early on is critical to the durability of the deck.

Maintaining your p-3012 steel form decks is equally important. Regular inspections and cleaning can prevent rust accumulation, while touch-up paint can protect against corrosion. Implementing these maintenance tips will ensure that your steel form decks remain in excellent condition over their lifespan.

Collaborating with teams using cloud-based solutions

In modern construction projects, collaboration is vital. Tools like pdfFiller offer a comprehensive document management platform that enhances teamwork efficiency. Creating, editing, and managing installation templates through the platform ensures all team members have access to up-to-date documents, facilitating seamless communication and project management.

Real-time collaboration on project documents further reduces the margin for error. By using features for eSigning forms related to p-3012 steel decks, teams can approve and finalize documents promptly. The cloud-based solution allows for easy archiving of project documents, ensuring every stakeholder has access to necessary records throughout the project lifecycle.

Troubleshooting common issues in steel form deck usage

Despite careful planning and execution, mistakes can occur during the installation of p-3012 steel form decks. Common errors may lead to alignment problems or structural weaknesses. It's important to identify these issues quickly; solutions often include readjusting panels or reinforcing support areas.

Long-term performance issues may arise due to wear or environmental factors. Signs of damage, such as rust or cracking, should prompt immediate remedial actions to maintain structural integrity. Regular maintenance checks allow teams to proactively address issues before they compromise the overall performance of the deck.

Interactive tools and resources

Visualizing your construction project becomes much easier with interactive tools available on platforms like pdfFiller. Utilizing these features for layout planning enables you to see the potential design of your p-3012 steel form deck before implementation. This proactive approach can lead to better design choices and more efficient use of resources.

Additionally, pdfFiller offers downloadable templates for packing lists, installation guides, and other helpful documentation. Leveraging these resources can simplify the creation of necessary paperwork, ensuring that all documentation complies with your project's standards.

Expert recommendations for successful projects

Professionals in the field often emphasize the importance of selecting the right materials when working on projects involving p-3012 steel form decks. Attention to factors such as gauge and coating can dictate the success of the project. Building relationships between various team members—architects, engineers, and contractors—plays a pivotal role in ensuring the project runs smoothly.

Looking into future trends, innovations in materials and technology are shaping the industry's landscape. Predictions indicate a shift towards more sustainable practices in steel usage and construction methods, presenting exciting opportunities for engineers and architects alike. Keeping abreast of these developments can position your projects at the forefront of modern construction.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit p-3012 steel form deck in Chrome?

How do I complete p-3012 steel form deck on an iOS device?

How do I complete p-3012 steel form deck on an Android device?

What is p-3012 steel form deck?

Who is required to file p-3012 steel form deck?

How to fill out p-3012 steel form deck?

What is the purpose of p-3012 steel form deck?

What information must be reported on p-3012 steel form deck?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.