Get the free Composite Polymer Granules Based on PolyCaprolactone and Montmorillonite Prepared by...

Get, Create, Make and Sign composite polymer granules based

Editing composite polymer granules based online

Uncompromising security for your PDF editing and eSignature needs

How to fill out composite polymer granules based

How to fill out composite polymer granules based

Who needs composite polymer granules based?

Composite Polymer Granules Based Form: A Comprehensive Guide

Overview of composite polymer granules

Composite polymer granules are materials that combine various polymers to enhance performance characteristics and tailor them for specific applications. These granules serve as a fundamental building block across numerous industries, playing critical roles in manufacturing and product development. Their versatility makes them indispensable in applications ranging from automotive components to specialized medical devices.

The importance of composite polymer granules stems from their ability to blend the strengths of different polymer types. This results in materials that can achieve superior mechanical properties, resistance to environmental factors, and economic efficiencies. Industries such as construction, packaging, and electronics increasingly rely on these granules to develop innovative solutions that meet stringent industry standards.

When compared to other polymer forms, composite polymer granules exhibit enhanced properties such as improved tensile strength and resistance to wear and tear. This positions them as an ideal choice in applications demanding high performance and longevity.

Unique characteristics of composite polymer granules

The unique characteristics of composite polymer granules derive from their complex compositions. Physically, they can vary in size, density, and color, while their chemical properties may include enhanced thermal stability and chemical resistance. These properties can be finely tuned during production, ensuring that the granules meet specific industry demands.

One significant benefit of composite polymer granules over traditional polymer forms is their adaptability. These granules can be designed to meet unique mechanical and thermal challenges while allowing for lighter and more cost-effective solutions. This aspect accelerates product innovation, especially in industries that rely on sustainable practices.

Environmental impact is a crucial consideration when discussing composite polymer granules. Many manufacturers are now focusing on using recycled materials in their formulations, which reduces waste and conserves resources. This sustainability approach not only improves the environmental footprint but also appeals to increasingly eco-conscious consumers.

Methods of creating composite polymer granules

Producing high-quality composite polymer granules involves several key steps and requires specific raw materials. Common base polymers, such as polyethylene, polypropylene, and polystyrene, are selected based on the intended application. Once the base polymers are chosen, the manufacturing process begins with blending techniques that ensure homogeneity and consistency.

Quality control measures are integral during the production of composite polymer granules. These measures often include monitoring the temperature, pressure, and flow rates within the granulation machinery. Innovations in manufacturing processes, such as the adoption of advanced extrusion techniques, have led to enhanced control and consistency in granule production.

Interactive tools for customization

To facilitate the custom formulation of composite polymer granules, various interactive tools are now available. These tools assist manufacturers and developers in optimizing their formulations and tailoring them to specific needs. Custom formulation calculators are essential for determining the ideal ratios of different polymers required to achieve desired properties.

Visualization tools play a significant role in helping users to understand the granule properties better. By simulating various conditions, these tools allow for adjustments to be made proactively, thus streamlining the development process. Additionally, interactive templates for documenting formulations enhance consistency and accuracy across project teams.

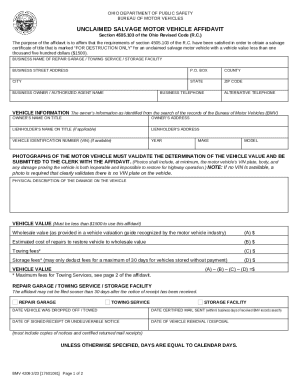

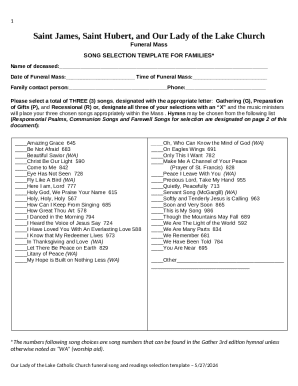

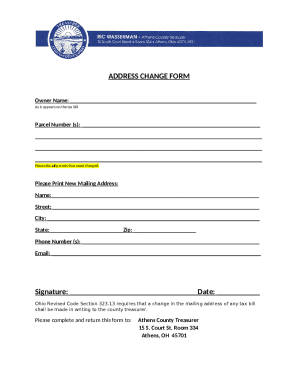

Filling out and managing forms related to composite polymer granules

In working with composite polymer granules, proper documentation is crucial for maintaining quality and compliance. Necessary forms may include specifications, safety data sheets (SDS), and production reports. Understanding how to accurately fill out these documents is vital for ensuring that all required information is clearly communicated.

Detailed instructions for completing product specification forms should focus on the most relevant data, such as material properties, processing parameters, and compliance certifications. Common pitfalls include overlooking vital information or misreporting data, which can lead to production delays or compliance issues. Therefore, thorough review processes are essential.

Collaborative processes in composite polymer projects

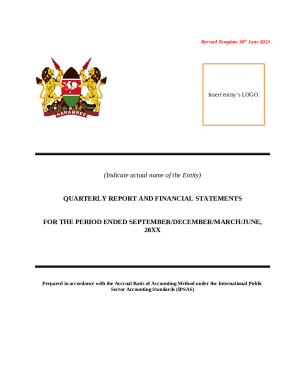

Collaboration is vital in ensuring successful outcomes in projects involving composite polymer granules. Teams can leverage cloud-based solutions for documenting and sharing information in real time. By centralizing project data, teams can maintain alignment throughout the development process.

Project management tools enhance overall efficiency by providing features for tracking progress, assigning tasks, and managing deadlines. Moreover, engaging in collaborative editing allows multiple team members to contribute simultaneously, fostering innovation and collective problem-solving. Best practices for effective team communication should include regular updates, transparent sharing of challenges, and to ensure all voices are heard.

Legal and regulatory considerations

Engaging with composite polymer granules also requires careful attention to legal and regulatory requirements. Compliance is essential for ensuring that products meet safety and environmental standards. Various regulations govern the use and disposal of polymers, and companies must stay informed regarding the relevant codes affecting their operations.

Important safety data sheets (SDS) must be maintained for every composite polymer granule formulation to inform users about potential hazards. Keeping documentation updated is not just a regulatory necessity but also a best practice that contributes to workplace safety. Regularly reviewing these documents guarantees that staff members are well-informed.

Case studies and success stories

Examining real-world applications of composite polymer granules illustrates their effectiveness and versatility. Case studies often highlight successful implementations in sectors such as automotive, where manufacturers have reported enhanced performance and reduced weight in vehicle components made from these granules. For instance, a notable automotive company adopted a custom blend of polymer granules that improved fuel efficiency while offering superior crash resistance.

Testimonials from industry experts underscore the growing reliance on composite polymer granules, citing examples where these materials have led to significant cost savings and product improvements. Lessons learned from these applications can guide future innovations, reinforcing the potential for development in this area.

Troubleshooting common issues

Despite their numerous advantages, issues can arise during the processing of composite polymer granules. Common problems include inconsistent granule size, which can affect product performance and batching uniformity. Identifying the root cause of these issues is crucial, as it aids in the effective resolution of the manufacturing process.

Solutions often involve adjustments to processing parameters or improvements in raw material quality. FAQs related to granule quality and performance usually center around the identification of defects and the impact of processing conditions on final product properties. Addressing these concerns proactively helps maintain the integrity of the manufacturing workflow.

Future trends in composite polymer granules

The landscape of composite polymer granules is rapidly evolving, with research focusing on bio-based polymers and nanocomposites. These innovations signify a shift towards more sustainable materials, which are expected to play an increasingly significant role in the future. Market predictions indicate robust growth, fueled by technological advancements and a rising demand for lighter, stronger materials across various sectors.

New applications for composite polymer granules are constantly emerging, particularly in fields such as electronics, where they are utilized to create lightweight housings and components. Ongoing advancements in manufacturing technology, such as 3D printing with polymers, are further broadening the scope for their use, promising to unlock new levels of performance and customization.

Conclusion: Unlocking the potential of composite polymer granules

The versatility and performance advantages offered by composite polymer granules underline their critical role in modern manufacturing processes. From automotive to electronic applications, these materials represent an essential nexus point for innovation and efficiency. Encouraging exploration of pdfFiller tools for document management related to composite polymer projects will enable teams to enhance collaboration and streamline their workflows.

Understanding the detailed processes and tools associated with these granules not only empowers product development but also ensures teams remain aligned in their goals. As the industry continues to evolve, harnessing the potential of composite polymer granules will undoubtedly lead to substantial advancements across various markets.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for the composite polymer granules based in Chrome?

How do I edit composite polymer granules based on an iOS device?

How do I complete composite polymer granules based on an Android device?

What is composite polymer granules based?

Who is required to file composite polymer granules based?

How to fill out composite polymer granules based?

What is the purpose of composite polymer granules based?

What information must be reported on composite polymer granules based?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.