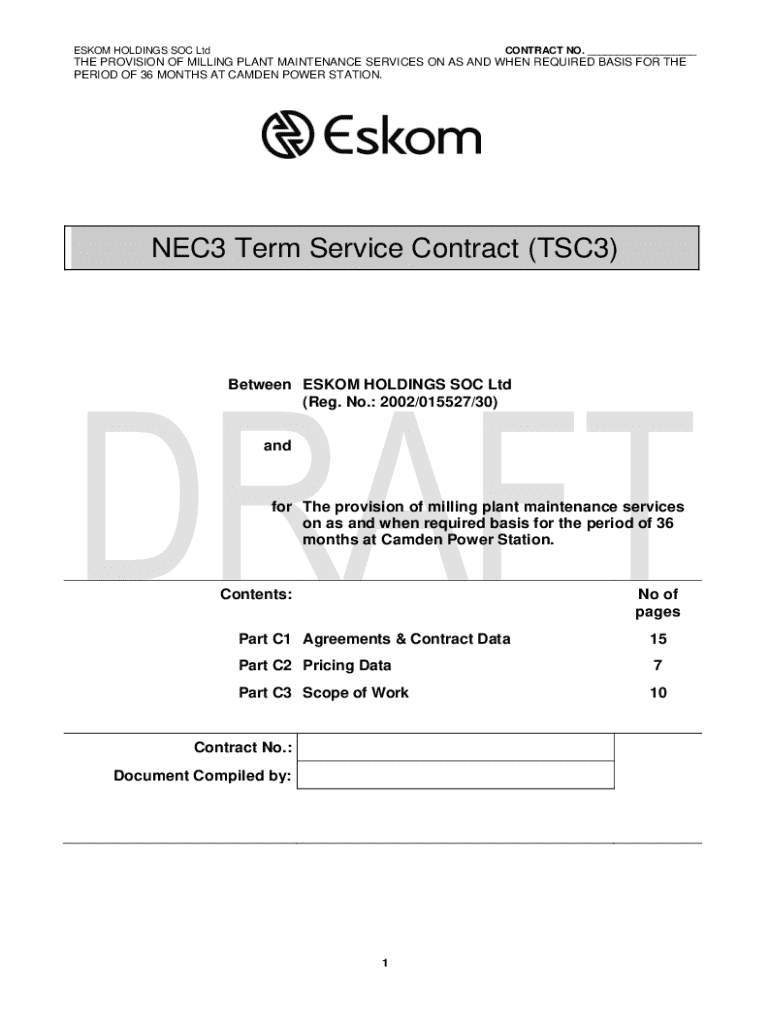

Get the free The provision of milling plant maintenance services on as ...

Get, Create, Make and Sign form provision of milling

How to edit form provision of milling online

Uncompromising security for your PDF editing and eSignature needs

How to fill out form provision of milling

How to fill out form provision of milling

Who needs form provision of milling?

Form provision of milling form: A comprehensive guide

Understanding milling forms

A milling form serves as an essential document in the milling process, providing structured information required for effective milling operations. It captures crucial details such as dimensions, tolerances, and specifications necessary for successful machining services. For industries ranging from automotive to aerospace, accurate milling forms help streamline workflows and ensure compliance with industry standards.

The milling process itself involves removing material from a workpiece using rotary cutters, which can create a wide variety of parts and products. Ensuring that the milling form is correct and complete directly impacts the efficiency of production and the quality of the final outputs.

Types of milling forms

Different forms are utilized in the milling process. Standard forms are typically pre-defined templates that cover most common milling operations, while custom forms are tailored for specific project needs. Additionally, electronic forms have gained popularity due to their convenience and efficiency, allowing for easier sharing and editing.

When comparing paper to electronic forms, electronic solutions provide significant advantages, including better access, reduced physical storage needs, and easy integration with various software tools. This shift towards digital documentation enhances team productivity and offers a smoother workflow.

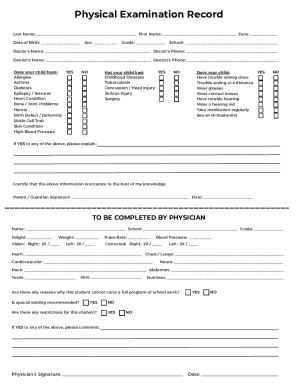

The anatomy of a milling form

A well-structured milling form comprises several key components that ensure information clarity and compliance with project requirements. These include header information, body sections detailing dimensions and specifications, as well as signature lines for approval.

Each section serves a critical purpose; for example, the header sets the context, while body sections ensure all machining requirements align with project goals. Completeness in these sections minimizes the likelihood of errors during the milling process.

Preparing to fill out a milling form

Before filling out a milling form, it's crucial to gather all necessary information. This includes project specifications and materials to be used. Successful preparation can significantly reduce the time spent filling out forms and prevent unnecessary delays.

Common mistakes include overlooking specific requirements or failing to verify accuracy. Thorough preparation can mitigate these risks, leading to smoother project execution.

How to fill out a milling form effectively

Completing a milling form requires attention to detail. Each section must be filled out meticulously to ensure communication is clear and precise. Begin with basic information, including the project name, date, and responsible individuals.

Double-checking written information is critical to maintain accuracy. Errors in dimensions or other specifications can result in costly adjustments during the milling operations.

Editing and reviewing your milling form

Once the form is completed, a thorough review process is essential. Utilize editing tools available within pdfFiller to make adjustments as necessary. Engaging team members for feedback can also ensure that all aspects of the form meet the project’s requirements.

Taking the time to review the milling form can prevent costly errors down the line, ensuring that operations proceed smoothly and on schedule.

eSigning and managing your milling form

The implementation of electronic signatures in the milling process simplifies the approval workflow and enhances efficiency. Using pdfFiller, users can eSign documents quickly, which speeds up the process of validation and compliance.

Managing your forms digitally ensures they are easily retrievable and maintain a professional appearance, which is vital in business operations.

Common challenges and solutions

Filling out milling forms can present challenges such as incomplete forms or misinterpretation of milling requirements. These issues can cause significant delays and impact project timelines.

pdfFiller addresses these challenges through its user-friendly features, including form templates, which guide users step-by-step while reducing the likelihood of errors. This makes the form provision of milling forms straightforward and efficient.

The future of milling forms

The digitization and automation of milling forms is an evolving trend that fundamentally improves how organizations manage documentation. The integration of cloud technology allows teams to collaborate more effectively, regardless of geographic boundaries.

As the landscape of milling operations shifts, staying informed about these changes will empower teams to enhance their efficiency and adaptability in an increasingly competitive environment.

FAQs about milling forms

Addressing common inquiries can help clarify concerns regarding milling form provision. Questions like what to do in case a milling form is rejected or how to maintain security while sharing forms are vital for ensuring smooth project execution.

Clarifying these aspects ensures everyone involved understands their roles and responsibilities throughout the milling process.

Interactive tools and resources

pdfFiller offers a robust suite of interactive tools for managing milling forms. From customizable templates to collaborative editing features, users can access resources that streamline their documentation process.

These interactive resources make form provision of milling forms not only efficient but also comprehensive, ensuring that users have everything they need at their fingertips.

User testimonials and case studies

Real-world examples often provide the best insights into the benefits of using digital documentation for milling forms. Many users have reported significant improvements in their workflows and reductions in processing times.

By adopting effective form provisions through solutions like pdfFiller, teams have effectively reduced errors and improved the quality of their deliverables, propelling overall project success.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I complete form provision of milling online?

How do I make changes in form provision of milling?

How do I edit form provision of milling in Chrome?

What is form provision of milling?

Who is required to file form provision of milling?

How to fill out form provision of milling?

What is the purpose of form provision of milling?

What information must be reported on form provision of milling?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.