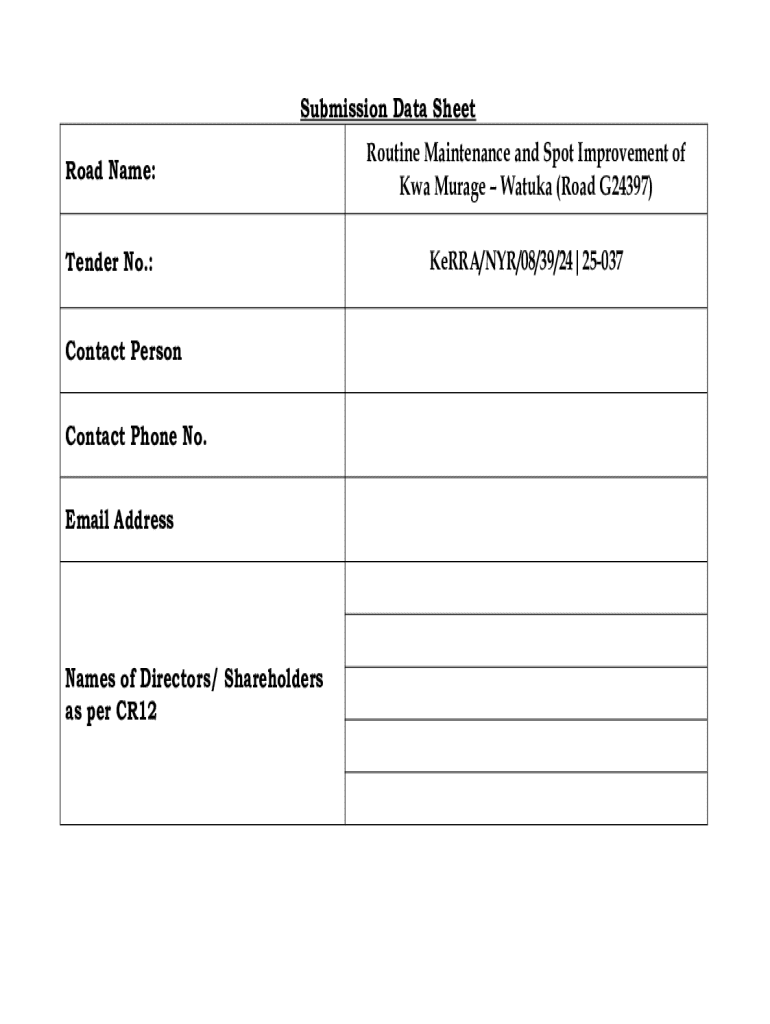

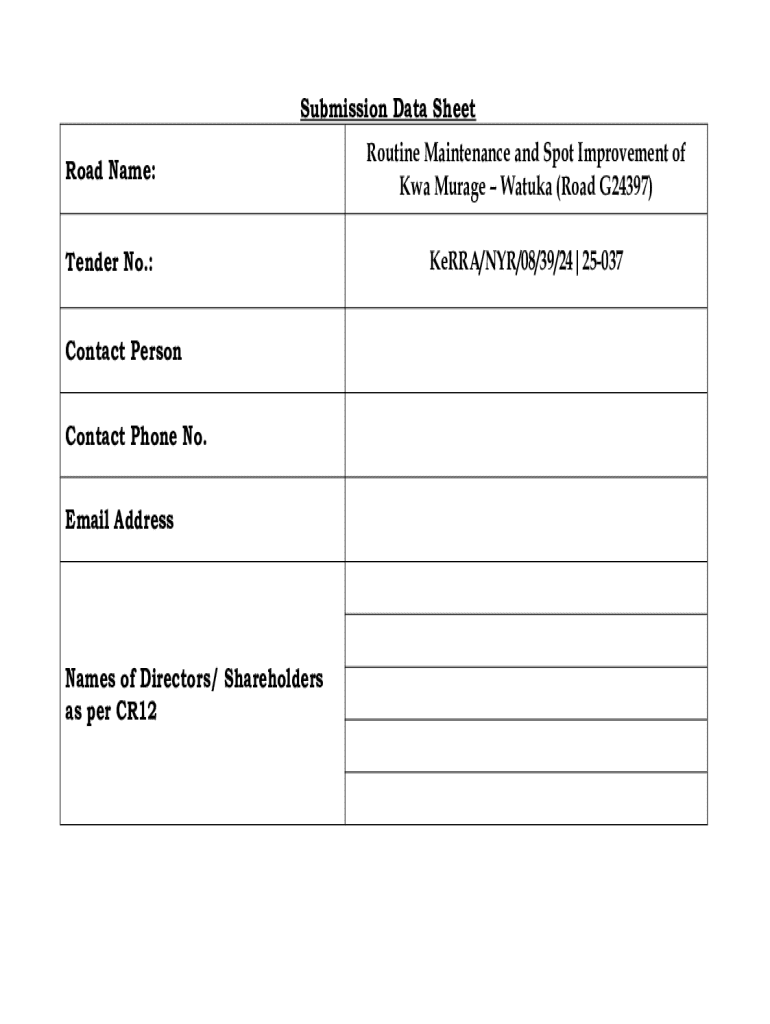

Get the free Routine Maintenance and Spot Improvement of Kwa ... - kerra go

Get, Create, Make and Sign routine maintenance and spot

Editing routine maintenance and spot online

Uncompromising security for your PDF editing and eSignature needs

How to fill out routine maintenance and spot

How to fill out routine maintenance and spot

Who needs routine maintenance and spot?

Routine Maintenance and Spot Form: A Comprehensive Guide

Understanding routine maintenance

Routine maintenance refers to the regular and systematic actions taken to preserve the functionality and reliability of assets. This proactive approach is essential across various industries, including manufacturing, healthcare, and facilities management, as it helps prevent unexpected breakdowns and extends the lifespan of equipment.

Implementing a routine maintenance program improves operational efficiency and reduces long-term costs associated with repairs and replacements. By investing in routine maintenance, companies can ensure their assets operate at optimum performance, decreasing downtime while enhancing productivity.

Spot form overview

A spot form is an essential document used during maintenance activities to capture immediate observations and actions taken regarding an asset. It allows maintenance teams to document specific incidents or conditions affecting equipment, facilitating smoother tracking and resolution. Spot forms are commonly used in industries such as manufacturing, commercial services, and residential management.

The benefits of using a spot form include improved communication among maintenance teams and efficient record-keeping for future reference. In industrial settings, spot forms can be employed to highlight equipment issues quickly, while in commercial spaces, they can document safety inspections or maintenance performed. For residential properties, spot forms can aid in tracking maintenance requests from tenants.

Key components of an effective maintenance strategy

A. Maintenance goals

Setting clear objectives for a maintenance program establishes a strong foundation for effective asset management. Maintenance goals should be aligned with organizational standards to ensure all team members are focused on common outcomes. For instance, objectives may include reducing equipment downtime by a specific percentage or enhancing service response times.

Involving the maintenance team in goal-setting fosters ownership and accountability. Regularly reviewing these goals ensures they remain relevant and allows organizations to adapt to evolving assets and operational demands.

B. Asset management

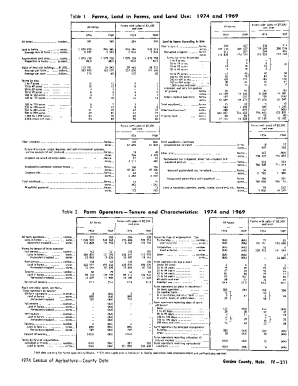

Tracking assets is vital for implementing an effective maintenance program. Organizations should develop an asset management policy that outlines how assets are monitored and maintained throughout their lifecycle. This includes maintaining accurate records of maintenance activities, tracking asset performance, and addressing potential issues proactively.

By utilizing an asset management system, companies can implement preventative measures and optimize their maintenance schedules, ultimately increasing asset reliability and longevity.

Templates for routine maintenance

To streamline maintenance activities, utilizing templates can enhance efficiency and consistency. Here are 12 essential maintenance templates and how to use them effectively:

Spot form development

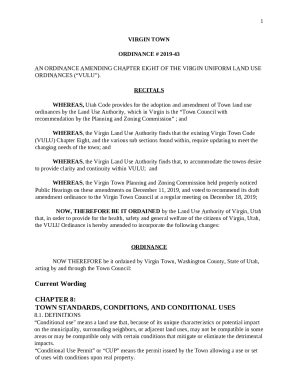

A. Designing a customized spot form

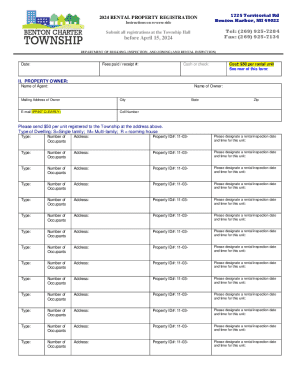

When designing a customized spot form, there are several key elements to include. These may encompass sections for date, time, location, and specific issues encountered. Additionally, incorporating fields for responsible personnel and follow-up actions ensures accountability and facilitates tracking of the issues reported.

To make your spot form effective, consider using simple language, ensuring clarity to all team members. Including a checklist for specific tasks can provide extra support in preventing details from being missed during documentation.

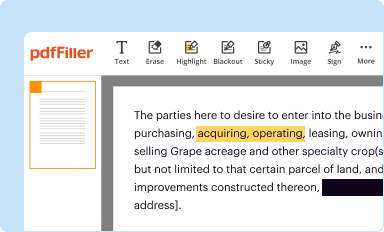

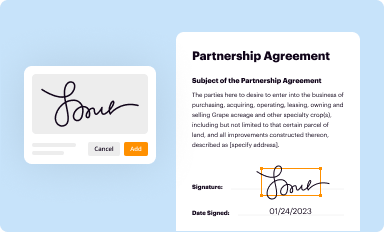

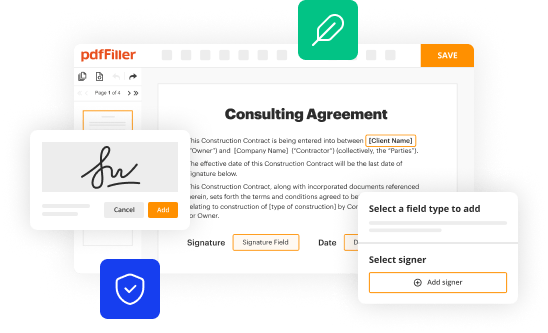

B. Using pdfFiller to create a spot form

Creating a spot form using pdfFiller is straightforward and user-friendly. Start by selecting a template that matches your needs, then personalize it by adding your company branding, specific fields, and any additional elements relevant to your maintenance tasks.

Additionally, pdfFiller enables eSigning and collaboration features, allowing multiple team members to review and sign off on maintenance records efficiently. This streamlines communication and ensures all involved parties have quick access to important documents.

Advanced strategies for routine maintenance

A. Calculating asset criticality

Identifying critical assets and understanding their impact on operations is an essential aspect of a robust maintenance strategy. Criticality assessments can help prioritize maintenance tasks based on the consequences of asset failure. For example, machinery vital to production workflow would require more frequent checks than non-essential equipment.

Utilizing data analytics tools can further enhance your ability to assess criticality by providing insights into asset performance and historical maintenance trends. This information can assist maintenance teams in making informed decisions regarding resource allocation and planning.

B. Prioritizing maintenance tasks

Effective prioritization of maintenance tasks ensures that teams focus efforts where they are needed most. Many organizations adopt a scoring system that ranks tasks based on urgency and impact. For example, urgent tasks affecting safety should take precedence over routine checks.

Implementing a visual management tool can also aid in tracking task priorities, giving your maintenance team clarity on what needs to be addressed first.

. Building a maintenance budget

Establishing a well-defined maintenance budget requires careful planning and consideration. Organizations must account for routine maintenance costs, unexpected repairs, and staffing needs when building their budgets. A transparent review process can facilitate future budgeting by analyzing past expenses and adjusting for inflation or changes in asset usage.

Engaging cross-functional teams in the budgeting process can also provide valuable insights, ensuring your budget aligns with operational demands and supports overall business objectives.

Parts management in maintenance

A. Checklist for parts purchasing and management

Effective parts management is crucial for minimizing downtime and ensuring maintenance activities are not hindered by a lack of necessary components. When purchasing and managing parts, it's essential to establish a checklist that considers factors such as vendor reliability, lead times, and inventory levels.

Reviewing historical usage trends can also help inform stocking decisions, ensuring that you maintain sufficient inventory without overstocking.

B. Template for kitting parts

Creating a template for kitting parts can organize components needed for specific maintenance tasks, streamlining the process and reducing delays. This template should categorize parts based on tasks and include quantities, ensuring maintenance teams have everything they need on hand before commencing work.

With the right template in place, kitting can improve efficiency, reduce errors, and enhance overall productivity, making it easier for maintenance teams to focus on their primary objectives.

Best practices for collaboration and document management

A. Utilizing document sharing tools

To enhance teamwork within maintenance groups, leveraging document sharing tools such as pdfFiller proves beneficial. These tools allow multiple team members to access, edit, and collaborate on maintenance documents in real time, leading to increased efficiency and clarity.

Promoting a culture of collaboration ensures that everyone is on the same page regarding maintenance activities, expectations, and timelines.

B. Standardizing maintenance documentation

Standardizing maintenance documentation is vital for ensuring all records are organized and easily accessible. Establishing guidelines for document formats, naming conventions, and storage procedures can save time searching for critical information. Moreover, standardization processes enhance accountability, as it becomes easier to track and audit maintenance activities over time.

Employing a centralized document management system like pdfFiller ensures all documents are secure, backed up, and readily retrievable.

Monitoring and continuous improvement

Evaluating the effectiveness of your maintenance strategy involves ongoing monitoring and assessment. Key performance indicators (KPIs) should be established to measure outcomes, such as equipment uptime, maintenance response times, and cost efficiency.

Utilizing analytics and reporting tools can facilitate thorough evaluations, allowing teams to adapt their routine maintenance approach based on findings. By fostering a culture of continuous improvement, maintenance teams can ensure optimal performance and align their efforts with organizational goals.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find routine maintenance and spot?

Can I sign the routine maintenance and spot electronically in Chrome?

Can I edit routine maintenance and spot on an iOS device?

What is routine maintenance and spot?

Who is required to file routine maintenance and spot?

How to fill out routine maintenance and spot?

What is the purpose of routine maintenance and spot?

What information must be reported on routine maintenance and spot?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.