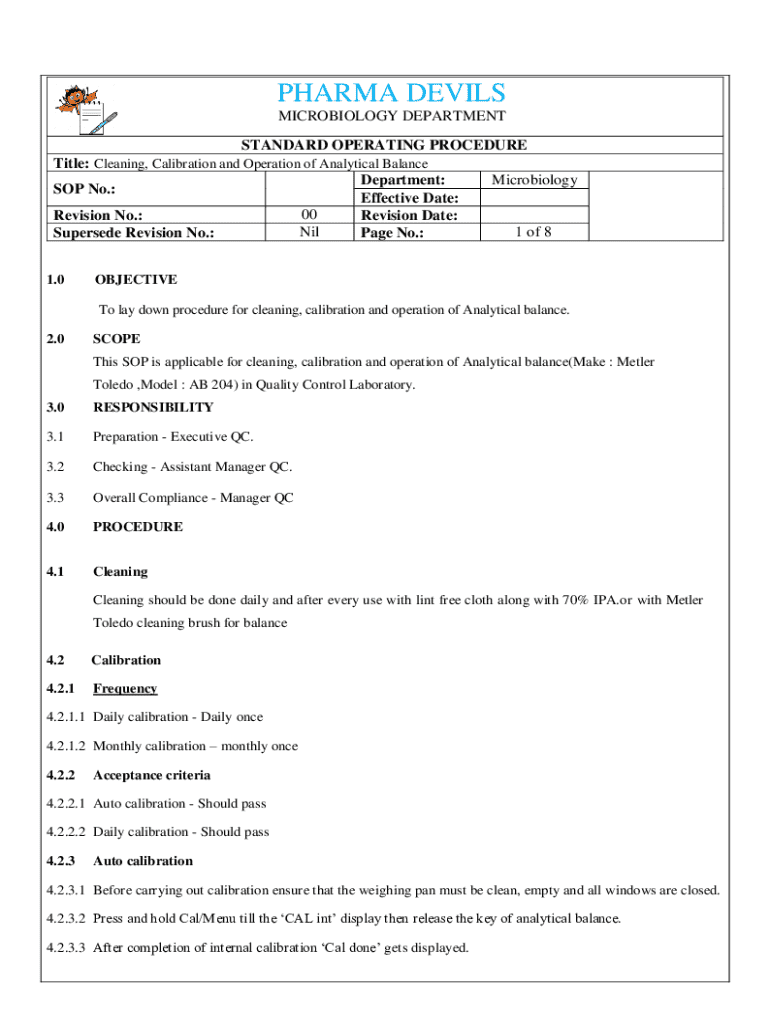

Get the free SOP for Cleaning, Calibration and Operation of Analytical ...

Get, Create, Make and Sign sop for cleaning calibration

Editing sop for cleaning calibration online

Uncompromising security for your PDF editing and eSignature needs

How to fill out sop for cleaning calibration

How to fill out sop for cleaning calibration

Who needs sop for cleaning calibration?

SOP for cleaning calibration form: A comprehensive guide

Purpose of the SOP for cleaning calibration form

The purpose of a Standard Operating Procedure (SOP) for cleaning calibration forms is multi-faceted, underscoring the critical nature of maintaining accurate and reliable calibration documentation. Calibration forms, whether they are in digital or paper format, serve as essential records that ensure the integrity of instruments used in production processes. By implementing a thorough cleaning protocol, facilities can uphold the cleanliness of these documents, which is pivotal for accurate data recording and analysis. Clean calibration forms prevent the introduction of errors, enhance compliance with regulatory standards, and foster trust in operational outputs.

Moreover, cleanliness goes beyond mere aesthetics; it plays a vital role in mitigating risks associated with contaminated records. Having clear, unobstructed, and legible forms allows engineers and operators to make informed decisions based on precise measurements. In this guide, we will explore the step-by-step processes involved in ensuring that cleaning protocols for calibration forms are well understood and effectively implemented.

Scope of the SOP

This SOP applies to all team members involved in the maintenance of calibration forms, including production personnel, quality assurance staff, and administrative support. By clearly outlining the cleaning process, everyone involved can maintain consistency and uphold the standards of cleanliness required for effective calibration procedures. The scope also encompasses various types of calibration forms, ensuring that the guidelines apply across electronic document formats and traditional paper documents, fulfilling the needs of diverse operational setups.

In addition, the SOP highlights the procedures necessary for maintaining compliance with industry standards concerning document management. By clearly defining the roles of the respective teams, organizations can reduce the risk of confusion and enhance teamwork, promoting a seamless workflow and a culture of responsibility. This thorough approach sets the stage for subsequent procedures outlined in this guide, making it easier for users to follow.

Definitions and terminology

Understanding key terminology related to the cleaning and calibration process is essential for clarity and proper execution. Some definitions include:

Understanding these terms can facilitate easier communication among team members and ensure adherence to protocols.

Responsibilities

Establishing clear roles and responsibilities for cleaning calibration forms enhances accountability and promotes effective training. Designated staff should include production personnel, who prepare documents for cleaning, and supervisors, who review cleaning protocols and ensure compliance. Each team member must understand their responsibility within the cleaning process to maintain the integrity of calibration documents.

Regular audits can reinforce these responsibilities, ensuring that personnel carry out their tasks according to the standards outlined in this SOP. In addition, the responsibility to report any discrepancies found during cleaning should be clearly defined, as this will further enhance the overall effectiveness of the calibration documentation process.

Cleaning procedures for calibration forms

Initial preparation

Before beginning the cleaning process, gather the necessary tools and materials. Required items may include:

Follow these steps to prepare your workspace before cleaning:

Surface cleaning protocol

Surface cleaning should be approached carefully to minimize the risk of damage to calibration forms. First, assess the type of form, whether it is electronic or paper-based, to select the appropriate cleaning method. For paper forms, lightly dampen a soft cloth with a cleaning solution recommended for general document cleaning, ensuring not to soak the material.

For electronic forms stored in devices, use a microfiber cloth dampened with appropriate cleaners that are safe for electronics. This will help clear away smudges without scratching screens or damaging the equipment. Here are some recommended cleaning techniques:

Lastly, remember that non-abrasive materials are essential for protecting the calibration forms and ensuring their longevity.

Handling sensitive information

When cleaning calibration forms containing sensitive data, handle documents with extra caution. Follow these guidelines to secure sensitive information during the cleaning process:

These protocols help safeguard confidential information while ensuring that the cleaning process is efficiently and effectively carried out without jeopardizing data integrity.

Calibration procedure review

Inspection of calibration forms

After cleaning, it is crucial to conduct a thorough inspection of calibration forms to verify their condition. The first step is to check that all physical documents are free from stains, tears, or other damage. If any issues are identified, these forms may require repair, or replacement may be necessary if they are beyond saving.

To ensure compliance and accuracy in calibration, consider these criteria:

Documentation completeness

Once the cleaning and inspection are complete, verify the completeness of all documentation. This involves cross-referencing the cleaned forms with a checklist of required data. In cases where discrepancies are identified, it is vital to document these findings to create an accurate trail of information for traceability.

Establish a clear process for recording any missing or incomplete information to facilitate follow-up actions. Consider implementing a checksum or digital confirmation system where applicable to reduce the margin for error and enhance accountability within the team.

Quality control measures

Reassessing cleaning effectiveness

To maintain a high standard of cleaning for calibration forms, it is vital to assess the effectiveness of the cleaning processes regularly. Recommended methods include random audits of cleaned documents to ensure adherence to cleanliness protocols and training staff on the importance of maintaining high standards.

Establish a frequency for these audits, whether quarterly or biannually, to foster a culture of quality assurance among staff members. Regular assessments not only help to identify weaknesses in existing procedures but also promote continuous improvement in the cleaning process.

Continuous improvement practices

Encouraging feedback from team members involved in the cleaning process is crucial to continually enhancing the cleaning protocols for calibration forms. Providing a platform for suggestions and feedback can lead to innovative solutions that streamline cleaning operations and uphold cleanliness standards. One effective way to implement feedback is through regular team meetings where staff share insights on current practices and propose refinements.

Training programs should be established to update personnel on best practices and new technologies that can further enhance the cleaning process.

Safety precautions

Safety is a top priority during the cleaning of calibration forms. Implement essential safety measures to protect personnel during the process, including the use of appropriate PPE. Recommended PPE may include gloves, safety goggles, and face protection to minimize exposure to cleaning agents and other hazards.

Ensure that all staff are trained on the proper use of PPE and familiarize them with the chemicals being used for cleaning. It’s also beneficial to establish clear emergency procedures for handling accidents or exposure incidents that may occur during the cleaning process.

Integrating technology into cleaning protocols

The integration of digital tools and software can significantly improve the cleaning protocols for calibration forms. Investing in advanced document management solutions, such as pdfFiller, ensures that all calibration forms are easily accessible and editable from anywhere. These solutions help streamline the process, minimizing human errors while ensuring that cleaning records are adequately maintained.

By utilizing cloud-based platforms, teams can store, clean, and manage their documents efficiently, which is crucial for maintaining compliance with industry standards for document preservation.

Interactive review and feedback

Leverage interactive tools offered by pdfFiller to facilitate collaborative reviews of cleaned calibration forms. Utilizing electronic signatures and annotations enables team members to propose adjustments or approvals directly on the documents, promoting a hassle-free review process.

This fosters teamwork and allows for immediate updates to forms, ensuring that all necessary modifications occur promptly. Encouraging a culture of interactive feedback can reinforce the importance of maintaining cleanliness and accuracy in calibration documentation.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find sop for cleaning calibration?

Can I create an electronic signature for the sop for cleaning calibration in Chrome?

How do I edit sop for cleaning calibration on an Android device?

What is sop for cleaning calibration?

Who is required to file sop for cleaning calibration?

How to fill out sop for cleaning calibration?

What is the purpose of sop for cleaning calibration?

What information must be reported on sop for cleaning calibration?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.