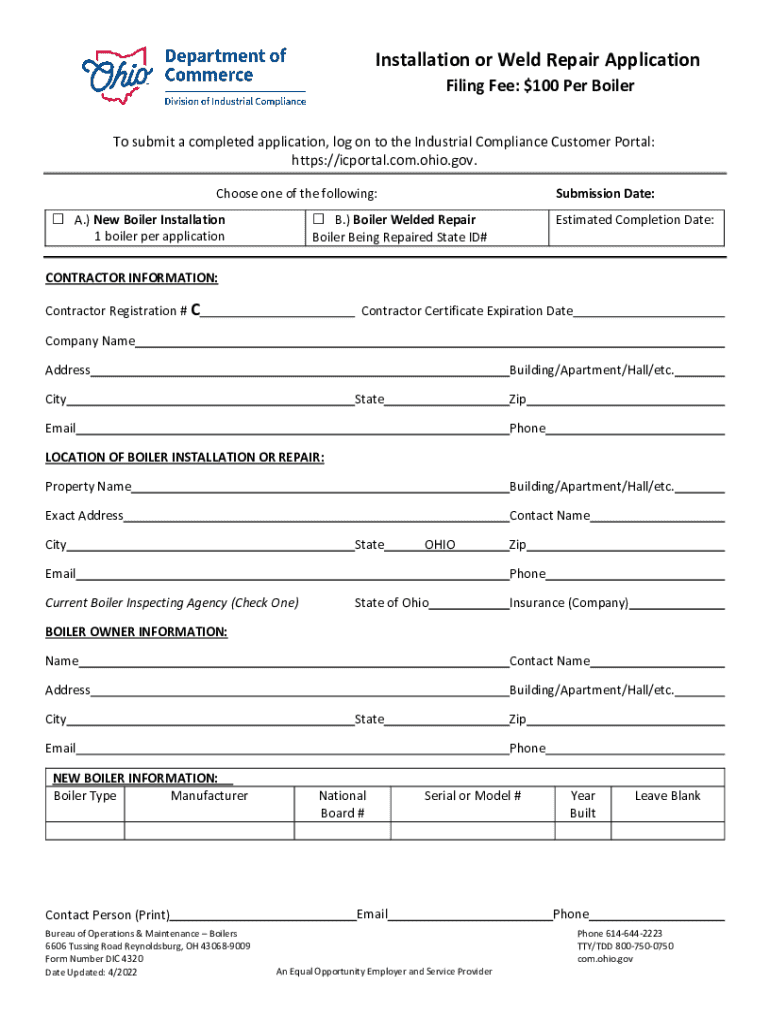

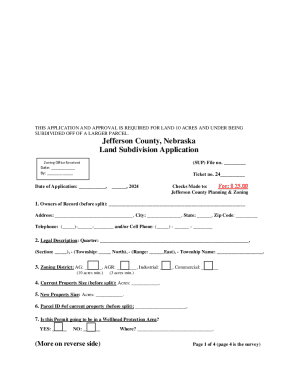

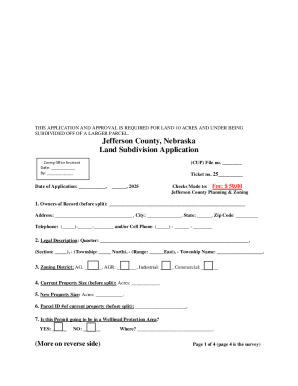

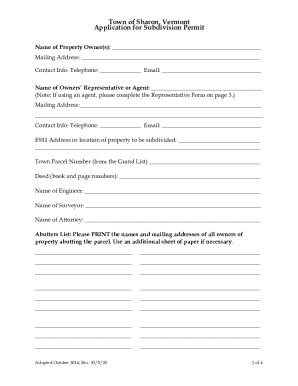

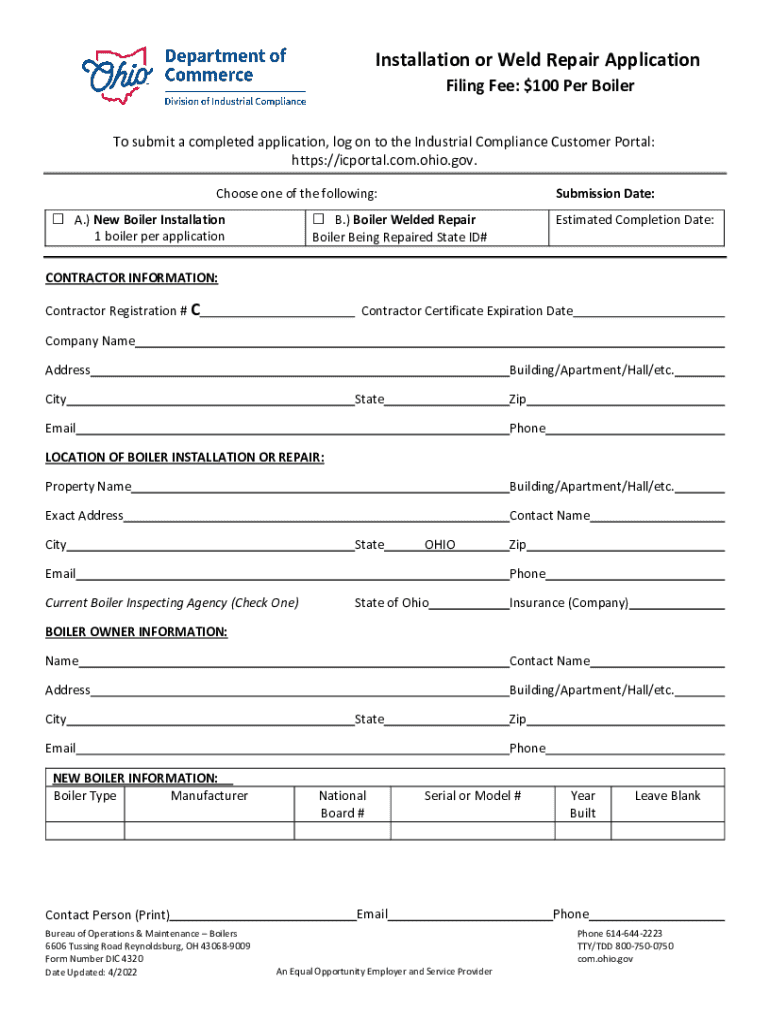

Get the free Installation or Weld Repair Application

Get, Create, Make and Sign installation or weld repair

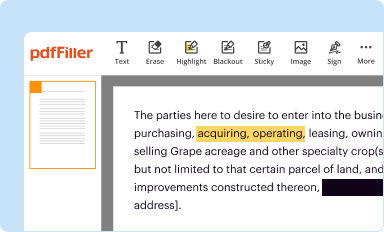

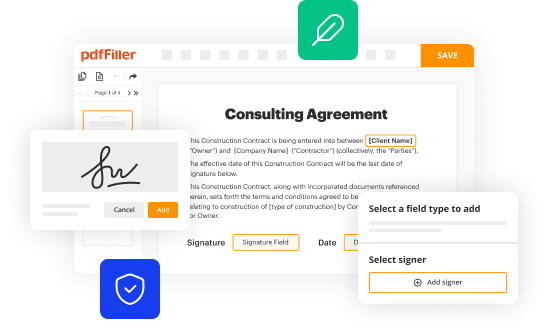

Editing installation or weld repair online

Uncompromising security for your PDF editing and eSignature needs

How to fill out installation or weld repair

How to fill out installation or weld repair

Who needs installation or weld repair?

Installation or Weld Repair Form: A Comprehensive Guide

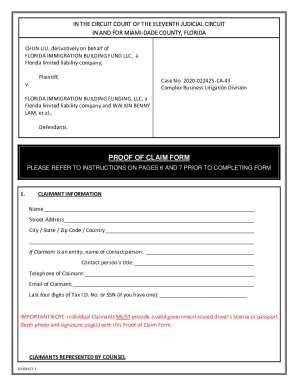

Understanding the installation or weld repair form

The installation or weld repair form is crucial for effective project management in industries such as construction, manufacturing, and engineering. These forms ensure that work follows legal and safety regulations, ultimately safeguarding the interests of both businesses and workers.

Submitting accurate installation or weld repair forms also has significant legal implications. Failing to comply with industry standards can lead to fines, project delays, and liability issues. Therefore, navigating this form properly is not merely an administrative task; it is an essential part of responsible project execution.

Components of the installation or weld repair form

Understanding the required sections of an installation or weld repair form is vital to completing it effectively. These components provide a comprehensive overview of the project and its specific details.

Key components typically include:

How to fill out the installation or weld repair form effectively

Filling out the installation or weld repair form can be straightforward if approached systematically. Here’s a step-by-step guide.

Before submitting the form, implement best practices such as double-checking all entered information and ensuring that all sections are completed without leaving blank fields.

Advanced features for managing your installation or weld repair form

pdfFiller not only lets you fill out your installation or weld repair form but also offers a variety of features to manage these documents effectively.

Common issues and troubleshooting

Despite its straightforward nature, users can encounter challenges when filling out the installation or weld repair form.

Common FAQs include questions about the difference between installations and repairs and the necessity of submitting the form for minor jobs. Understanding these elements is crucial for effective form usage.

Success stories: Impact of proper form usage

Real-world examples illustrate how accurate installation or weld repair form submissions significantly enhance project success. Companies that religiously adhered to submission guidelines often reported smoother operations and fewer compliance issues.

Professional testimonials from users of pdfFiller highlight the platform's efficiency in managing forms and documents. Quotes from satisfied customers can provide additional insights into the tool’s tangible benefits.

Staying updated: Regulations and compliance

Regulations govern installation and weld repairs, and these rules continuously evolve. Keeping abreast of industry standards is vital for compliance and project success.

Utilizing resources like pdfFiller can facilitate the educational journey concerning the latest developments in operational compliance.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send installation or weld repair to be eSigned by others?

How can I get installation or weld repair?

How do I complete installation or weld repair online?

What is installation or weld repair?

Who is required to file installation or weld repair?

How to fill out installation or weld repair?

What is the purpose of installation or weld repair?

What information must be reported on installation or weld repair?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.