Get the free TWO CYCLE GASOLINE ENGINE OIL PERFORMANCE ...

Get, Create, Make and Sign two cycle gasoline engine

How to edit two cycle gasoline engine online

Uncompromising security for your PDF editing and eSignature needs

How to fill out two cycle gasoline engine

How to fill out two cycle gasoline engine

Who needs two cycle gasoline engine?

Two Cycle Gasoline Engine Form: A Comprehensive Guide

Understanding the two cycle gasoline engine

Two cycle gasoline engines, also known as two-stroke engines, are a type of internal combustion engine that completes a power cycle in just two strokes of the piston. Unlike four-cycle engines, which require four distinct strokes to complete an entire power cycle, two-cycle engines utilize both the intake and exhaust processes in one full cycle. This design simplifies the engine’s architecture, allowing for fewer moving parts, which can reduce manufacturing costs and complexity.

The key principle behind two-cycle engine operation involves the piston’s up-down motion, which alternately compresses the fuel-air mixture and expels exhaust gases. This operational simplicity is a major differentiator compared to four-cycle engines, leading to a lighter and more compact design.

Components of a two cycle gasoline engine

Understanding the critical components of a two cycle gasoline engine is essential for grasping its functionality and performance. The primary components include the crankshaft, piston, cylinder, and exhaust ports. The crankshaft converts the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. The piston moves within the cylinder, which houses the fuel-air mixture, and is crucial for the engine’s intake and compression phases.

Additionally, exhaust ports play a vital role in directing exhaust gases out of the cylinder, ensuring efficient engine operation. Diagrams illustrating these components can help visualize how they work together to produce power.

The two cycle engine cycle explained

The operational cycle of a two cycle gasoline engine is both ingeniously simple and efficient, consisting of four main phases: intake, compression, power, and exhaust. During the intake phase, as the piston descends, it creates a vacuum that draws in an air-fuel mixture from the crankcase into the cylinder. Next, as the piston moves upward, this mixture is compressed, raising its temperature and pressure, preparing it for combustion.

In the power phase, a spark ignites the highly compressed mixture, causing a rapid expansion of gases that forces the piston downwards. This output effectively translates to the rotation of the crankshaft. Finally, during the exhaust phase, the piston rises again, pushing the burnt gases out through the exhaust ports, thus completing the cycle.

Compared to four-cycle engines, two-cycle engines typically have higher fuel efficiency in certain applications but also tend to produce higher emissions due to less complete combustion. This efficiency, however, can vary based on engine design and operational conditions.

Two-cycle oil

Two-cycle engines require a specific blend of fuel and oil to operate efficiently. This mixture serves multiple purposes, including lubrication, ensuring that moving parts run smoothly and reducing wear and tear. The main types of oil used in two-cycle engines include mineral-based and synthetic blends. Each oil type has distinct properties that can affect the engine's performance and longevity, making the choice of oil crucial for optimal operation.

Choosing the correct oil ratio is essential, as an improper mix can lead to engine malfunctions, increased emissions, and reduced performance. For most applications, a typical oil ratio ranges from 50:1 to 32:1, where higher ratios indicate less oil in the mixture. Calculators are commonly available to help users determine their specific ratios depending on engine specifications.

Creating the perfect oil

To effectively create the perfect oil mix for your two cycle gasoline engine, precision is key. Follow these steps to ensure a well-balanced fuel mixture: Begin by referring to your engine's specifications to determine the recommended oil-to-fuel ratio. Measure out the amount of fuel you will use, and then calculate the corresponding amount of oil based on the ratio. For instance, if you're mixing 1 gallon of fuel at a 50:1 ratio, you'd add 2.6 ounces of oil.

Once you've obtained the correct quantities, combine the oil and fuel in a clean, non-reactive container. Shake or mix the container thoroughly to ensure even distribution of oil throughout the fuel. It's also advisable to label the container clearly, noting the mix ratio and date of preparation, to avoid confusion during storage.

Important warnings and maintenance tips

Maintaining a two cycle gasoline engine is vital for longevity and optimal performance. One common mistake is using the wrong oil mix, which can lead to excessive wear, reduced performance, and premature engine failure. Always double-check ratios and the type of oil suitable for your specific engine. Additionally, using stale fuel or failing to change the oil regularly can result in buildup within the engine, leading to clogs and inefficiencies.

Regular maintenance practices include cleaning and inspecting spark plugs, checking fuel filters, and replacing deteriorating parts. Ensure your exhaust ports are clear to prevent gas buildup, which can affect performance. Always consult the owner’s manual for specific maintenance schedules.

Categorization of two cycle engine variants

There are several types of two-cycle engines, each engineered for specific uses and applications. Common categories include lightweight engines typically used in handheld tools such as chainsaws and leaf blowers, as well as heavier variations found in motorcycles and small outboard motors. Each variant exhibits unique features and performance specifications tailored to its application.

For example, portable two-cycle engines boast lower weight and compact design, allowing greater maneuverability. In contrast, heavy-duty two-cycle engines are designed for higher output, offering better torque and speed for performance-oriented applications.

The future of two cycle gasoline engines

With increasing regulations on emissions, the two cycle gasoline engine is evolving. Innovations such as direct fuel injection and improved exhaust designs are emerging, allowing for enhanced performance while reducing harmful emissions. Some manufacturers are even investigating hybrid models that introduce electric components to complement traditional two-cycle offerings.

The industry is also focusing heavily on biodegradable lubricants and eco-friendly fuels to counteract the environmental impact traditionally associated with two-cycle engines. This shift denotes a hopeful future where the robust performance of two-cycle engines can coexist with sustainable practices.

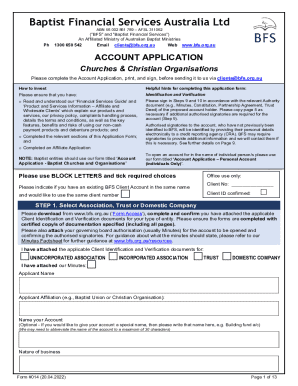

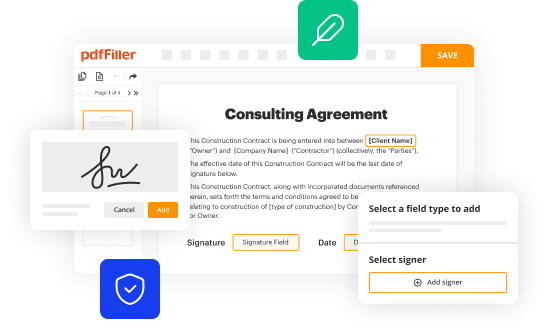

Utilizing pdfFiller for two cycle gasoline engine documentation

Managing documentation for two cycle gasoline engines can be streamlined using pdfFiller. With an array of tools designed for document creation and management, users can easily edit PDFs related to engine specifications, maintenance logs, and repair records. The platform’s intuitive interface empowers individuals and teams to generate, fill out, and sign necessary documents without the hassle of traditional paper forms.

Collaboration is made easy with pdfFiller's eSigning solutions, allowing multiple stakeholders to review and approve documents seamlessly. The ability to access and store engine forms from anywhere enhances workflow efficiency and ensures that vital information is always at your fingertips.

Interactive tools and resources

To fully understand the capabilities of two cycle gasoline engines, engaging with interactive tools and resources can be highly beneficial. Users can access engine specifications and performance charts that detail the output capabilities and other critical measurements of various models. These resources not only assist in making informed purchasing decisions but also in optimizing engine use.

Moreover, community forums present a valuable space where users can share insights, troubleshooting tips, and best practices for maintaining two cycle engines. By participating in discussions, users can also learn from the experiences of others, creating a collaborative dialogue that enhances their understanding of two-cycle technologies.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find two cycle gasoline engine?

Can I edit two cycle gasoline engine on an iOS device?

How can I fill out two cycle gasoline engine on an iOS device?

What is two cycle gasoline engine?

Who is required to file two cycle gasoline engine?

How to fill out two cycle gasoline engine?

What is the purpose of two cycle gasoline engine?

What information must be reported on two cycle gasoline engine?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.