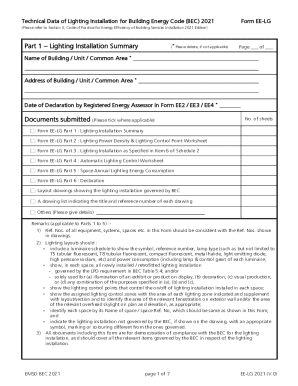

Comprehensive Guide to Electrical Systems Prefunctional Checklist Form

Understanding the electrical systems prefunctional checklist

An electrical systems prefunctional checklist is a critical tool utilized in the commissioning phase of electrical installations. It provides a systematic method to ensure all components of the electrical system are operational and compliant before becoming fully functional. By assessing key elements such as equipment status, connection integrity, and operational readiness, the checklist plays a pivotal role in identifying potential failures and enhancing safety standards.

The significance of this checklist cannot be overstated; it ensures buildings not only meet safety regulations but also operate efficiently from the outset. Inadequate checks can lead to catastrophic failures, system malfunctions, or even safety hazards, putting lives at risk and incurring substantial costs due to repairs and delays. Therefore, incorporating a comprehensive checklist into your project management is essential for maintaining compliance and safeguarding the operational integrity of the electrical systems.

Enhances safety through rigorous pre-installation checks.

Ensures compliance with local codes and regulations.

Minimizes potential risks associated with electrical failures.

Promotes efficient project execution and resource management.

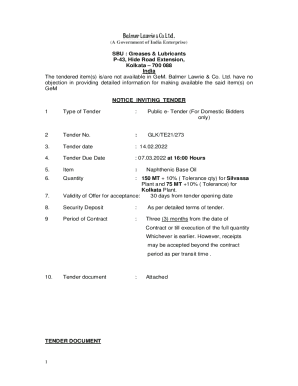

Preparing the electrical systems prefunctional checklist

Creating an effective electrical systems prefunctional checklist begins with identifying key stakeholders involved in the electrical project. Engineers, electricians, inspectors, and project managers all play integral roles in developing and validating the checklist. Their collaborative efforts ensure that all critical aspects of the installation are covered, and diverse expertise is included in the evaluation process. This teamwork approach not only enhances the checklist's effectiveness but also promotes accountability among team members.

To prepare a comprehensive checklist, various tools and resources can assist in its development. Software solutions, such as pdfFiller, allow for easy customization and accessibility of templates. By utilizing such platforms, checklists can be created and edited in a streamlined fashion, facilitating quick adjustments as project requirements evolve. Additionally, accessing pre-existing templates can save time and mitigate errors, providing a solid foundation for project-specific needs.

Diverse roles: involve engineers, electricians, inspectors, and project managers.

Utilize software like pdfFiller for easy customization.

Leverage templates to save time and improve accuracy.

Foster collaboration among stakeholders for a holistic approach.

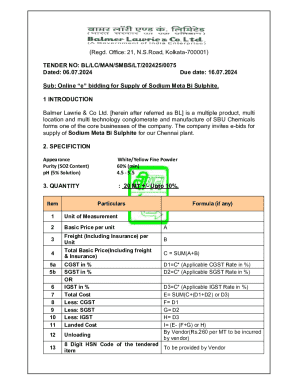

Detailed breakdown of the checklist items

Before any electrical system installation takes place, it is vital to conduct thorough inspections on key items. These pre-installation inspection items include checking that all necessary electrical equipment is present, functional, and compliant with specifications. Furthermore, assessing the condition of wiring, circuit breakers, and ancillary equipment helps uncover any pre-existing damage that could lead to problems later on. Effective documentation of these checks will also serve as a reference point during future maintenance assessments.

Verification of the installation site is another critical aspect of the checklist. Ensuring that the site meets safety standards and is adequately prepared for installation can prevent costly setbacks. Items to be verified may include adequate grounding, correct circuit layouts, and safety access points. Delivery inspections should follow, ensuring that all equipment received is undamaged and matches ordered specifications, ultimately establishing a clear foundation for installation success.

Inspect for equipment availability and functionality.

Assess condition of wiring and infrastructure.

Conduct site verification for compliance and readiness.

Implement delivery inspection for all electrical components.

Executing the electrical systems prefunctional checklist

Conducting inspections per the electrical systems prefunctional checklist requires meticulous attention to detail. Begin with a step-by-step guide, documenting each action taken during the inspection process. This includes recording any findings or observations, which provide critical evidence for compliance and can inform future project iterations. Rigorously following the checklist and immediately addressing discrepancies can reduce risks and ensure that the installation is on schedule.

Utilizing pdfFiller during checklist completion enhances efficiency. Users can fill out the electrical systems checklist digitally, allowing for easier corrections and updates. This platform offers user-friendly features, enabling the editing and customizing of forms based on specific project needs. Keeping the checklist accessible at all project stages empowers teams to provide consistent updates and maintain documentation integrity.

Follow a detailed inspection guide, recording every step.

Document observations and findings for accountability.

Utilize pdfFiller for a seamless digital checklist process.

Ensure easy editability to adapt the form for future projects.

Managing checklist completion and follow-up

After the checklist is completed, effective management of checklist results allows teams to maintain accountability and transparency. Collaborative features in platforms like pdfFiller facilitate teamwork by enabling multiple stakeholders to view and edit the checklist, thereby enhancing communication and coordination. This transparency in submitting results ensures that all team members are informed and actively participating in generating solutions to address any non-compliance issues.

When discrepancies are identified, addressing them promptly is crucial. Establishing a checklist for corrective actions can streamline the resolution process. This may include assigning responsible parties, setting deadlines for follow-up, and documenting actions taken to rectify issues found during inspections. By adopting such measures, teams can ensure that electrical systems remain compliant and safe throughout the project lifecycle.

Leverage collaborative features for team communication.

Submit checklist results for group review and engagement.

Implement a corrective actions checklist for discrepancies.

Assign responsibilities and deadlines promptly.

Post-inspection follow-up

Once inspections have been completed, the organization and storage of checklist data become essential to ensure its integrity for future reference. Utilizing pdfFiller allows teams to maintain a centralized digital archive of completed checklists, making retrieval straightforward whenever needed. Best practices for document management include establishing clear naming conventions and folder structures that facilitate efficient searches and safeguard important documentation.

Continuous improvement forms the backbone of effective project management. Teams can leverage insights gained from completed checklists to enhance future project assessments. Regularly revisiting and updating checklist items based on team feedback will ensure that they are relevant and effective over time. Scheduled reviews of the checklist allow for the integration of new findings or significant changes to local codes, ultimately contributing to improved standards in safety and compliance.

Maintain a digital archive for easy access to checklist data.

Establish clear naming conventions for organization.

Utilize feedback for continuous improvement of checklists.

Schedule regular reviews to incorporate updates and changes.

Advanced tips for electrical inspections

To enhance accuracy in electrical system assessments, embracing technology is beneficial. Utilizing specialized tools and apps can provide more efficient data collection and analysis during inspections, allowing for immediate adjustments to be made. Digital checklists, like those offered by pdfFiller, can streamline the process, reducing the chance of errors found in traditional paper formats while simplifying information sharing across teams.

Engaging with industry experts can provide valuable insights on effective inspection strategies. Their experience can reveal best practices that improve checklist usability and overall efficiency. Case studies highlighting successful implementations of prefunctional checklists demonstrate the importance of adapting processes to meet the specific challenges of electrical installations, ensuring compliance and optimal system performance.

Leverage technology to enhance inspection accuracy.

Utilize tools and apps for easier data gathering.

Engage with industry experts for best practices.

Assess case studies to learn from successful implementations.

Related topics and further exploration

The electrical landscape is constantly evolving, and understanding the role of maintenance in electrical systems can help ensure longevity and reliability. Regular checks and maintenance schedules contribute significantly to system performance and safety. Exploring future trends in electrical safety and compliance, including emerging technologies and practices, prepares teams for upcoming challenges in the field. Continued education in electrical inspections will empower professionals to stay updated on industry standards and requirements.

Explore the importance of regular maintenance in electrical systems.

Stay informed about future trends in electrical safety.

Pursue ongoing education for best practices in inspections.

Latest articles and insights

The electrical industry is ever-changing, making it crucial to stay updated on the latest practices and standards. Industry standards undergo regular revisions, and being aware of these updates helps keep projects compliant and safe. New tools and technologies emerge regularly to support efficient electrical systems management, providing teams with innovative solutions to tackle their challenges. Following emerging best practices in prefunctional checklists creates a foundation for solid project completions and maximizes operational potential.

Stay updated on revisions to industry standards.

Discover new tools for efficient electrical management.

Adopt best practices in prefunctional checklist utilization.

Author credentials and expertise

The insights presented in this guide come from experienced professionals in the electrical engineering field. Contributors bring a wealth of knowledge from diverse backgrounds, encompassing significant project management, engineering, and inspection roles. Their collective expertise ensures that readers receive up-to-date information about electrical systems prefunctional checklists and best practices for successful project completion.