Get the free STANDARD TOLERENCES TO APPLY UNLESS OTHERWISE SPECIFIED

Get, Create, Make and Sign standard tolerences to apply

Editing standard tolerences to apply online

Uncompromising security for your PDF editing and eSignature needs

How to fill out standard tolerences to apply

How to fill out standard tolerences to apply

Who needs standard tolerences to apply?

Standard tolerances to apply form: A comprehensive guide

Understanding the importance of standard tolerances

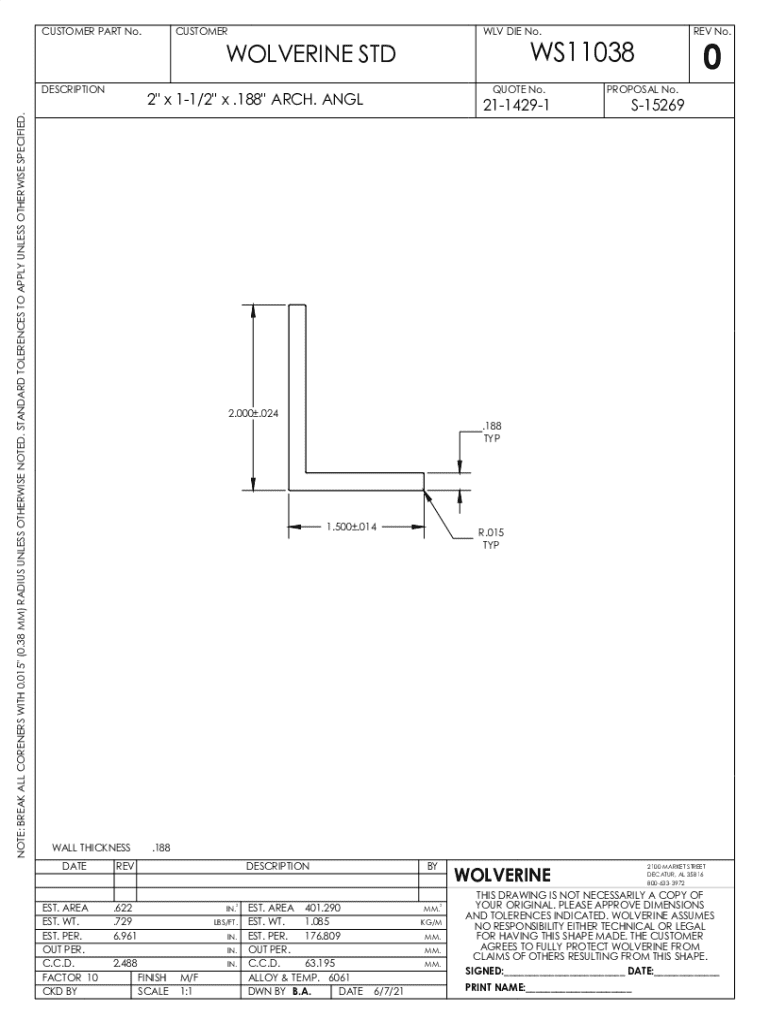

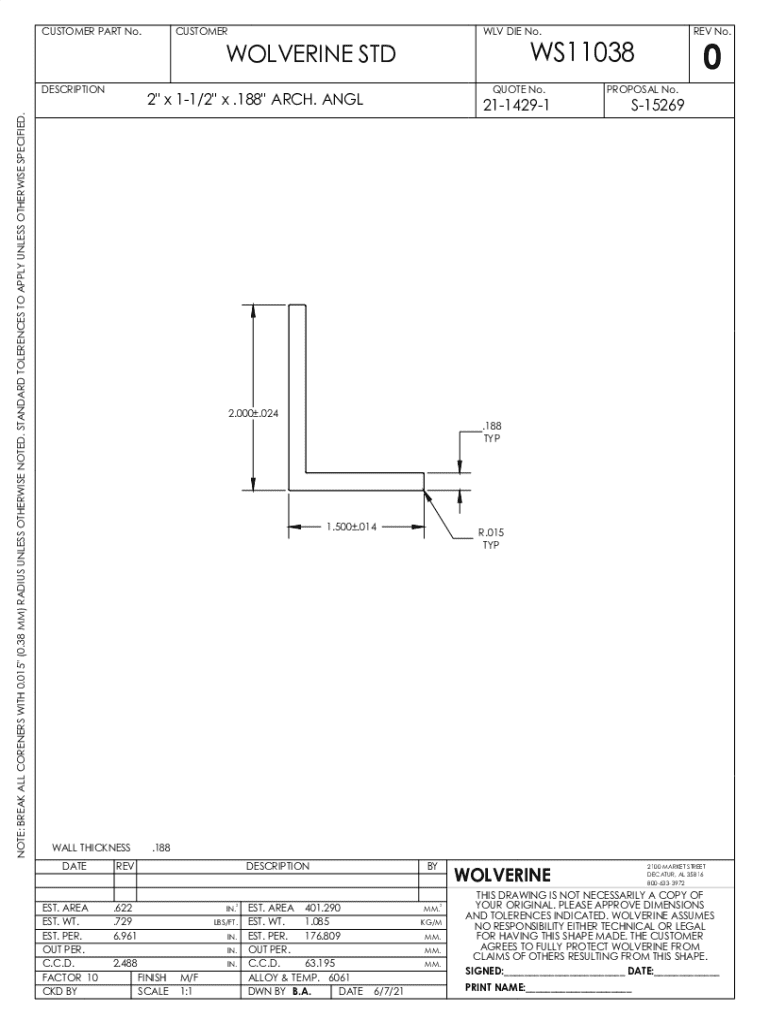

Standard tolerances refer to the permissible limits of variation in physical dimensions in manufacturing and engineering processes. They play a critical role across various industries, ensuring that parts manufactured meet the necessary specifications to enable compatibility and performance. Without standard tolerances, engineers and manufacturers would encounter challenges in assembly, performance, and ultimately quality control.

Tolerances are particularly essential in precision-driven fields like aerospace, automotive, and medical device manufacturing where the slightest deviation can lead to product failures or safety hazards. Additionally, they help harmonize parts and components sourced from different manufacturers, facilitating global supply chains and reducing costly rework or scrap rates.

Overview of relevant ISO standards

The International Organization for Standardization (ISO) has established several standards that govern tolerances, notably ISO 2768 and ISO 286. These standards provide frameworks for defining general tolerances and fit tolerances, respectively, ensuring consistency and reliability in manufacturing.

ISO 2768: General tolerances

ISO 2768 specifies general tolerances for linear and angular dimensions that apply to parts when no tolerances are defined. This standard is categorized into fine, medium, and coarse tolerances, making it versatile for various applications. For instance, a fine tolerance is usually applied in high-precision engineering for parts like gears, whereas coarse tolerances may be acceptable for larger structural components.

The practical application of ISO 2768 can be observed in creating engineering drawings where general tolerances can be indicated instead of detailing every single dimension, thus simplifying documentation and reducing the chance of errors.

ISO 286: Fit and tolerances

ISO 286 delineates different types of fits, primarily the clearance fit and interference fit. These terms refer to the way components fit together; clearance fit allows for space between parts, while interference fit ensures parts are tightly joined. Understanding these fits is crucial as they impact the functionality and manufacturability of assemblies.

Key terms within ISO 286, such as 'H7' (a common standard for holes) and 'g6' (for shafts), clarify precision levels acceptable in production. The implications are significant during assembly because non-compliance with fit and tolerances can lead to operational issues or performance failures.

Geometric dimensioning and tolerancing (GD&T)

GD&T is a symbolic language used on engineering drawings to accurately specify tolerances and define geometrical features. It provides a comprehensive vocabulary and system that indicates how parts should be manufactured and inspected. Symbols represent different tolerances, such as profile, orientation, and location, significantly reducing ambiguity.

The importance of GD&T in the application of standard tolerances cannot be overstated. By using GD&T, engineers can effectively communicate their design intent, allowing for a more efficient manufacturing process with less room for interpretation, which ultimately reduces costs and improves product quality.

How to choose the right tolerance for your project

Choosing the right tolerance is pivotal for ensuring a project meets its functional requirements. Several factors influence this decision, including the type of material being used. Materials like metals may withstand tighter tolerances compared to plastics due to their properties and stability under stress.

Manufacturing processes also dictate the tolerances that can be achieved. For example, CNC machining can typically achieve finer tolerances than traditional machining methods. Understanding assembly requirements is equally crucial, as selecting the wrong fit can lead to component failure or excessive wear.

Common pitfalls in tolerance selection include applying overly tight tolerances that do not add value but increase manufacturing costs or failing to adhere to industry standards. A comprehensive understanding of these factors is essential for making informed decisions.

Tools and resources for applying standard tolerances

Utilizing interactive tools can vastly enhance the practicality of applying standard tolerances effectively. Platforms such as pdfFiller offer features that enable users to edit, document, and collaborate on tolerance specifications with remarkable ease. Users can create and modify forms that encompass all necessary tolerance information.

Collaboration is simplified as team members can input and review tolerance specifications in real-time, ensuring every aspect is aligned with project requirements. The availability of customizable templates for various industries facilitates fast and efficient documentation while aligning with standard tolerances.

Real-world applications of standard tolerances

The impact of standard tolerances extends into numerous industries, and several case studies demonstrate their success. Take the aerospace sector, where the implementation of tight tolerances is not just a regulatory requirement but a necessity for safety and functionality. For example, the use of precise tolerances in the manufacturing of turbine engines leads to enhanced durability and efficiency.

In the automotive industry, however, the challenge balances cost against precision. Companies often adopt lean manufacturing techniques, which integrate standard tolerances to maintain quality while reducing waste. This has shown a measurable increase in overall production efficiency.

Measured outcomes from these implementations include reduced failure rates, enhanced customer satisfaction, and improved competitive positioning, underscoring the importance of effectively applying standard tolerances.

Frequently asked questions (FAQ) about standard tolerances

Many professionals have expressed concerns regarding the application of standard tolerances. Common queries typically revolve around how to measure deviations accurately and the challenges in applying tolerances across different materials. Troubleshooting guides often emphasize that misalignment in tolerances can lead to significant production issues, reinforcing the need for thorough inspections and proper documentation.

Moreover, clarifications on ISO standards, such as what they mean and how to achieve compliance, are frequently sought after. This highlights the necessity for trainings and workshops that address tolerance application best practices.

Best practices for documenting and communicating tolerances

Effective documentation of standard tolerances is vital. Using appropriate symbols in technical drawings that align with both ISO standards and industry expectations fosters clear communication among engineers and manufacturers. It’s essential to include tolerances directly next to dimensions to avoid confusion during the manufacturing process.

In communicating tolerances, teams should engage consistently through tools like pdfFiller to share documents and provide feedback in real time. Employing templates can streamline this process. Furthermore, maintaining clear notes on tolerance discussions and decisions aids in creating a knowledge base that can be referenced in future projects.

Exploring future trends in tolerances

The landscape of manufacturing is undergoing rapid transformations, and understanding future trends in tolerances is crucial for staying competitive. Innovations in materials and manufacturing techniques, such as additive manufacturing or 3D printing, challenge traditional tolerance applications by allowing for more complex geometries and potentially tighter tolerances.

Moreover, the integration of artificial intelligence and automation into manufacturing processes can enhance tolerance calculations and checks, reducing human error. As industries evolve, so must the standards and methodologies associated with tolerances, ensuring they are adaptable to new technological advancements.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit standard tolerences to apply online?

How do I fill out standard tolerences to apply using my mobile device?

How do I fill out standard tolerences to apply on an Android device?

What is standard tolerances to apply?

Who is required to file standard tolerances to apply?

How to fill out standard tolerances to apply?

What is the purpose of standard tolerances to apply?

What information must be reported on standard tolerances to apply?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.