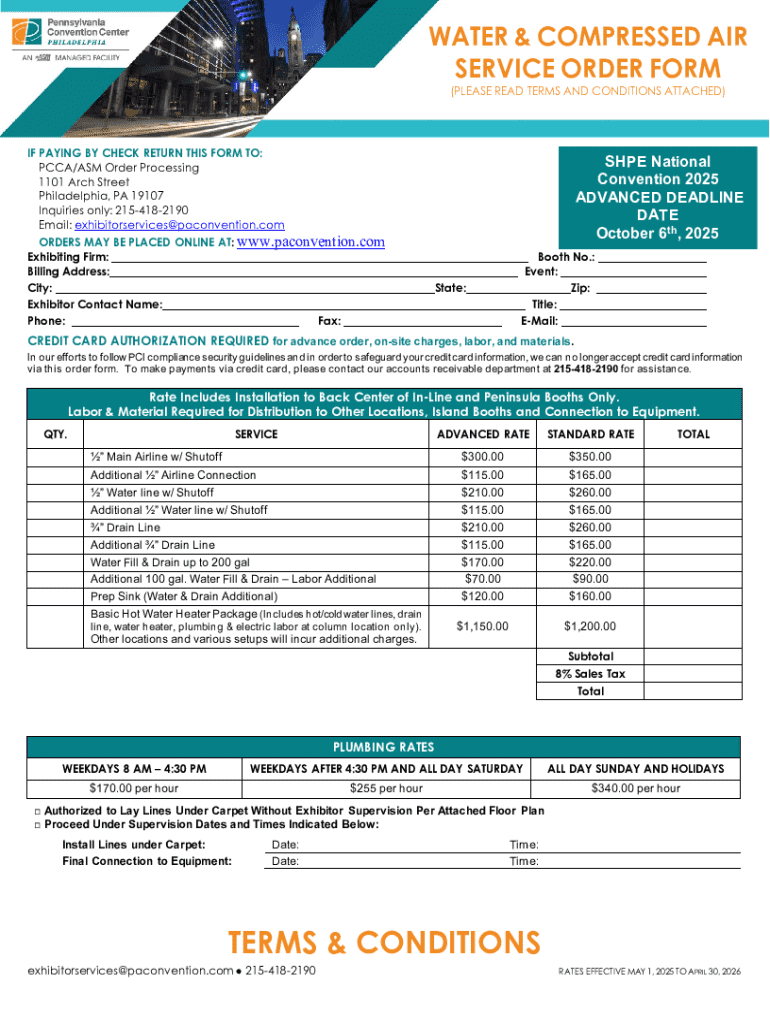

Get the free WATER & COMPRESSED AIR

Get, Create, Make and Sign water compressed air

How to edit water compressed air online

Uncompromising security for your PDF editing and eSignature needs

How to fill out water compressed air

How to fill out water compressed air

Who needs water compressed air?

Understanding Water Compressed Air Form: Essential Insights for Effective Moisture Management

Understanding compressed air and its importance in industrial applications

Compressed air is a vital energy source in many industrial settings, serving a plethora of functions from powering pneumatic tools to providing energy for assembly operations. The importance of compressed air is underlined by the fact that it’s exceedingly versatile and can be found in diverse sectors such as manufacturing, construction, and food processing. However, its usability can be severely hampered by the presence of water, which accounts for one of the most common contaminants in compressed air systems.

Managing water effectively within these systems is crucial, as excess moisture can lead to corrosion, decreased equipment lifespan, and compromised product quality. Industries that rely on compressed air must prioritize water management to maintain operational efficiency and reduce costs associated with equipment failure and downtime.

The science behind water formation in compressed air systems

The presence of water in compressed air is primarily due to humidity in the ambient air that is drawn into compressors. Thermodynamic principles dictate that air can hold water vapor, and as the air is compressed, this vapor can condense into liquid water. The moisture content is influenced by factors such as temperature, pressure, and relative humidity. For example, increasing the pressure of air decreases its capacity to hold water vapor, leading to condensation.

Understanding these interactions can help technicians predict when and where water will form in a system. Additionally, the management of these properties is imperative when designing and operating compressed air systems to mitigate against water contamination.

Identifying water issues in compressed air lines

The presence of water in compressed air lines can manifest through various symptoms that signal the need for immediate attention. Common indicators include visible signs such as rust forming on metal components, water pooling at the base of air receivers, and a drop in air quality. Additionally, equipment suffering from water contamination may experience erratic performance and increased wear, further degrading efficiency.

Moreover, moisture can directly affect production quality, potentially leading to defective outputs in manufacturing processes. Diagnosis frameworks that include visual assessments along with functional impact evaluations can identify moisture levels effectively. The reduction in equipment efficiency will often correlate to increased energy costs, highlighting the importance of proactive water management in compressed air systems.

The diagnosis of water in compressed air systems

A systematic approach to diagnosing water-related issues in compressed air systems is essential for effective resolution. The process begins with a thorough inspection of the air receiver and associated piping systems. Look for any moisture accumulation and perform visual checks on filters and separators, as faulty equipment here often contributes to water contamination.

Next, analyzing the operational conditions—temperature, pressure, and humidity—is crucial. The use of specialized tools for measuring moisture levels, such as hygrometers and dew point testers, can provide accurate data to inform decision-making. Regular servicing and timely replacements based on diagnostic outcomes will help maintain optimal performance and minimize moisture-related issues.

Preventing water contamination in compressed air

Preventive measures are critical to managing water contamination effectively. Utilizing drying agents such as desiccants and refrigeration dryers is a proven method for controlling moisture levels in compressed air systems. These systems work by removing excess humidity before it can condense into liquid form, thus safeguarding vital components.

Proper piping design also plays a vital role in moisture prevention, highlighting the importance of slopes and drains that facilitate proper drainage. Regular maintenance involving inspections and equipment checks is essential for catching moisture issues early, ensuring efficient operations and prolonging equipment lifespan. Without these practices, companies risk facing not only equipment degradation but also significant production losses.

Infrastructure design considerations for moisture control

When designing air systems, considering moisture control is paramount. Strategic placement of drain points and moisture separators can significantly enhance system performance. Drains should be positioned at low points where condensation is likely to accumulate, allowing for proactive moisture management.

Incorporating heat exchangers into the system plays a beneficial role in condensing moisture, drawing heat from the compressed air, which allows for moisture to collect and be drained effectively. Such designs enhance operational reliability while bolstering efficiency, thus resulting in overall energy savings. Typical systems harness these features to minimize water in air lines and improve longevity.

Regulatory compliance and safety considerations

Adhering to regulatory standards regarding moisture management in compressed air systems is essential for maintaining safety and operational integrity. Regulatory frameworks set forth guidelines that facility managers must follow to ensure compliance and to mitigate risks associated with water contamination.

Safety risks can include equipment failures due to corrosion, leading to potential safety hazards for workers and bystanders. Establishing a clear written scheme of examination and ensuring adherence to best practices in maintenance and monitoring can help facilities minimize these risks. Moreover, regular audits for compliance can further safeguard against potential liabilities.

Advanced solutions for managing water in compressed air

The emergence of advanced technologies has significantly impacted moisture management in compressed air systems. Smart filters equipped with IoT capabilities facilitate real-time monitoring of moisture levels, enabling immediate responses to fluctuations.

Integrating digital tools into air systems not only enhances monitoring capabilities but also streamlines maintenance processes. Case studies demonstrate successful implementations across various industries, showcasing improvements in energy efficiency and decreases in water-related issues. Employing technology not only optimizes maintenance schedules but also enhances overall operational reliability, providing valuable insights for ongoing management.

Building a customized water management strategy

Establishing an effective water management strategy involves a comprehensive assessment of the current system capabilities. Identifying objectives focused on compliance needs while also selecting appropriate technological solutions, such as those provided by leading platforms like pdfFiller, is crucial. Implementing and monitoring these strategies will allow teams to respond proactively to moisture issues.

Furthermore, collaboration tools such as pdfFiller can streamline documentation processes, allowing teams to create necessary reports and quickly sign off on moisture-related action plans. This efficiency not only enhances day-to-day operations but also contributes to seamless compliance with regulatory requirements.

Conclusion of moisture management and its impact

Effective water management in compressed air systems yields numerous benefits, ranging from enhanced equipment longevity to improved product quality. Industries embracing best practices in moisture control will witness decreased operational costs, catapulting them ahead of competition. It is imperative for manufacturing sectors and others reliant on compressed air to adopt innovative solutions and practices for moisture management.

Platforms such as pdfFiller empower organizations to streamline document creation and management processes, enhancing communication and expediency in addressing moisture-related issues. By fostering a culture that prioritizes effective moisture management, companies can not only secure compliance but also enhance operational performances across the board.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my water compressed air in Gmail?

How can I send water compressed air to be eSigned by others?

How do I complete water compressed air online?

What is water compressed air?

Who is required to file water compressed air?

How to fill out water compressed air?

What is the purpose of water compressed air?

What information must be reported on water compressed air?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.