Get the free Industrial Electrical/Electronic Control Technology Level-II

Get, Create, Make and Sign industrial electricalelectronic control technology

How to edit industrial electricalelectronic control technology online

Uncompromising security for your PDF editing and eSignature needs

How to fill out industrial electricalelectronic control technology

How to fill out industrial electricalelectronic control technology

Who needs industrial electricalelectronic control technology?

Industrial Electrical/Electronic Control Technology Form - A Comprehensive Guide

Overview of industrial electrical/electronic control technology forms

Industrial electrical/electronic control technology forms serve as critical frameworks in the management and operational functionality of complex systems within industrial settings. These forms define the required specifications and procedures that ensure safe, effective, and compliant operations. Their importance lies not only in improving operational efficiencies but also in facilitating regulatory adherence, thereby minimizing risks and enhancing safety.

Key components typically included in such control technology forms encompass detailed specifications for wiring configurations, testing protocols, safety inspections, and compliance checklists. Including these elements helps standardize processes across deployable technologies, ensuring that all team members are on the same page and procedures are consistently executed.

Key types of industrial control technology forms

When navigating industrial electrical/electronic control technology forms, it's essential to recognize the various types that are pivotal to operational success. Each type serves a distinct purpose, ensuring that operations run smoothly while adhering to safety standards.

Electrical safety inspection forms

Electrical safety inspection forms are integral in assessing a facility’s safety protocols. They typically require details such as test results, equipment specifications, and safety gear usage. Common standards referenced include the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) regulations. By adhering to these standards, organizations can proactively address potential hazards.

Maintenance and troubleshooting logs

Maintenance and troubleshooting logs are vital for tracking system functionality and preventative maintenance activities. Effective record-keeping is paramount here, and best practices include the clear documentation of service dates, technician notes, parts replaced, and problems encountered. Accuracy is paramount since it ensures any recurring issue is promptly addressed.

Installation and commissioning checklists

Installation and commissioning checklists require scrutiny before a new system goes live. Essential points might include equipment verification, wiring checks, and compliance with electrical codes. Regulatory requirements often dictate specific inspections that need to be completed before a system can be activated, making this form a critical component of the startup process.

Understanding the target audience

Industrial control technology forms cater to a diverse audience, including engineers, technicians, and safety inspectors. Each group relies on these forms to facilitate their responsibilities effectively. For instance, engineers might need highly technical forms detailing specific electrical specifications, while technicians may benefit from simplified checklists that guide routine inspections.

Tailoring documentation for various user groups ensures that the information is relevant and applicable. For engineers, highly detailed forms may be needed to address particular components, while safety inspectors benefit from straightforward checklists that emphasize compliance and safety measures. Understanding these distinctions is crucial for effective communication and implementation across teams.

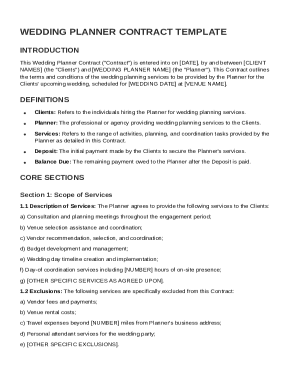

Creating effective industrial control technology forms

Crafting effective industrial control technology forms requires a deliberate approach to ensure clarity and functionality. A step-by-step guide offers an outline for teams aiming to improve their documentation.

Effective communication is key; hence, it's advisable to gather and present information clearly. Use straightforward language and a logical structure. Utilizing examples of well-structured forms can further enhance understanding.

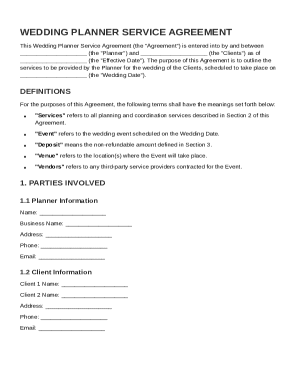

Editing and customizing your forms

Editing and customizing your industrial control technology forms is made effortless with pdfFiller’s cloud-based platform. Users can seamlessly upload existing PDF forms and tweak them to suit specific needs.

Adding, removing, or formatting text fields allows for a tailored approach that meets various procedural standards. Incorporating digital signatures enhances the validation of the forms, confirming authenticity and compliance. Additionally, the collaborative editing features support team usage, further streamlining workflows.

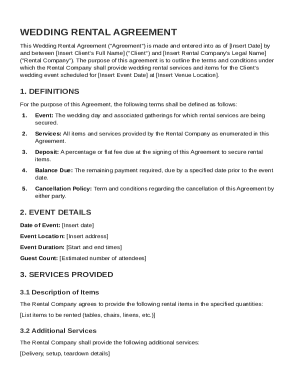

Managing and storing industrial control forms

Effective management and storage of industrial control forms is vital for operational efficiency. Organizing documents in the cloud enhances accessibility and backs up important data. Setting up a structured hierarchy for file storage allows for quick retrieval of necessary forms. Establishing best practices for version control and document updates ensures that the most current, relevant information is always accessible.

Data security remains high on the agenda, necessitating adherence to regulatory standards. Compliance with guidelines such as those from the General Data Protection Regulation (GDPR) safeguards sensitive information while allowing teams to manage crucial documents efficiently.

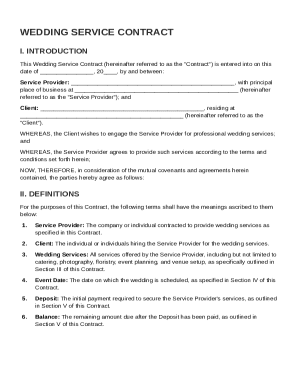

Benefits of using pdfFiller for industrial control technology forms

pdfFiller significantly enhances individual and team productivity when it comes to managing industrial control technology forms. Its seamless editing capabilities for a variety of environments eliminate common barriers associated with document modification.

Moreover, the platform promotes collaboration among team members. Multiple users can work on the same document simultaneously, ensuring that any amendments made are instantly saved and accessible. This feature boosts productivity and enhances cooperation, ultimately leading to better outcomes in documentation management.

Accessibility from any device enables users to handle forms anytime and anywhere, breaking down traditional barriers to productivity.

Case studies: successful use of control technology forms

Real-world applications of industrial control technology forms demonstrate their effectiveness in various scenarios. In a manufacturing plant, the integration of structured control forms streamlined processes, prevented costly downtime, and ensured safe operational parameters were met consistently. The process allowed for quick resolution of any discrepancies, fostering a continual improvement culture.

Similarly, an electrical contractor improved their safety measures by implementing thorough safety inspection forms. The result was a marked decrease in workplace incidents, and feedback indicated that technicians found the structured approach helpful in maintaining compliance. These examples illustrate the tangible benefits that come from well-managed control technology documentation.

Common challenges and solutions in form management

Common challenges in managing industrial control forms often include poor organization, lack of adherence to standards, and difficulties in collaboration. Identifying these pitfalls is the first step toward improving documentation processes. pdfFiller offers tailored solutions to address these challenges, such as improved form templates, streamlined editing processes, and enhanced collaboration tools.

Employing tips for continuous improvement and best practices, like regular reviews of existing forms and keeping them updated with the latest regulatory changes, can further enhance usability and compliance.

Future trends in industrial control technology documentation

Emerging technologies such as Artificial Intelligence (AI) and automation are set to influence the future of industrial control technology documentation significantly. Automation tools will enhance the efficiency and accuracy of form filling while AI-driven analytics may provide insights into improving practices across the board.

As industries continue to embrace digital transformation, platforms like pdfFiller are evolving to meet future needs. Enhanced functionalities will likely include advanced data analytics and predictive capabilities to forecast maintenance needs, ultimately fostering more robust operational frameworks.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit industrial electricalelectronic control technology from Google Drive?

Can I edit industrial electricalelectronic control technology on an iOS device?

How do I fill out industrial electricalelectronic control technology on an Android device?

What is industrial electrical electronic control technology?

Who is required to file industrial electrical electronic control technology?

How to fill out industrial electrical electronic control technology?

What is the purpose of industrial electrical electronic control technology?

What information must be reported on industrial electrical electronic control technology?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.