Get the free Industrial Electrical/Electronic Control Technology LEVELII

Get, Create, Make and Sign industrial electricalelectronic control technology

How to edit industrial electricalelectronic control technology online

Uncompromising security for your PDF editing and eSignature needs

How to fill out industrial electricalelectronic control technology

How to fill out industrial electricalelectronic control technology

Who needs industrial electricalelectronic control technology?

Understanding industrial electrical/electronic control technology forms

Understanding industrial electrical/electronic control technology forms

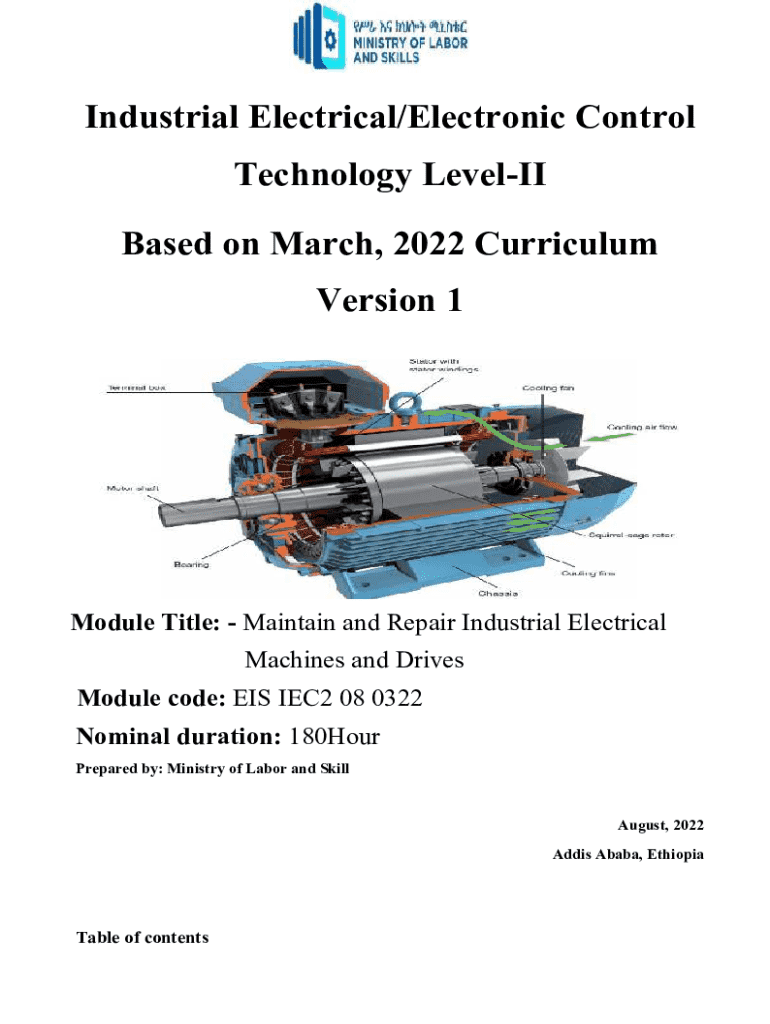

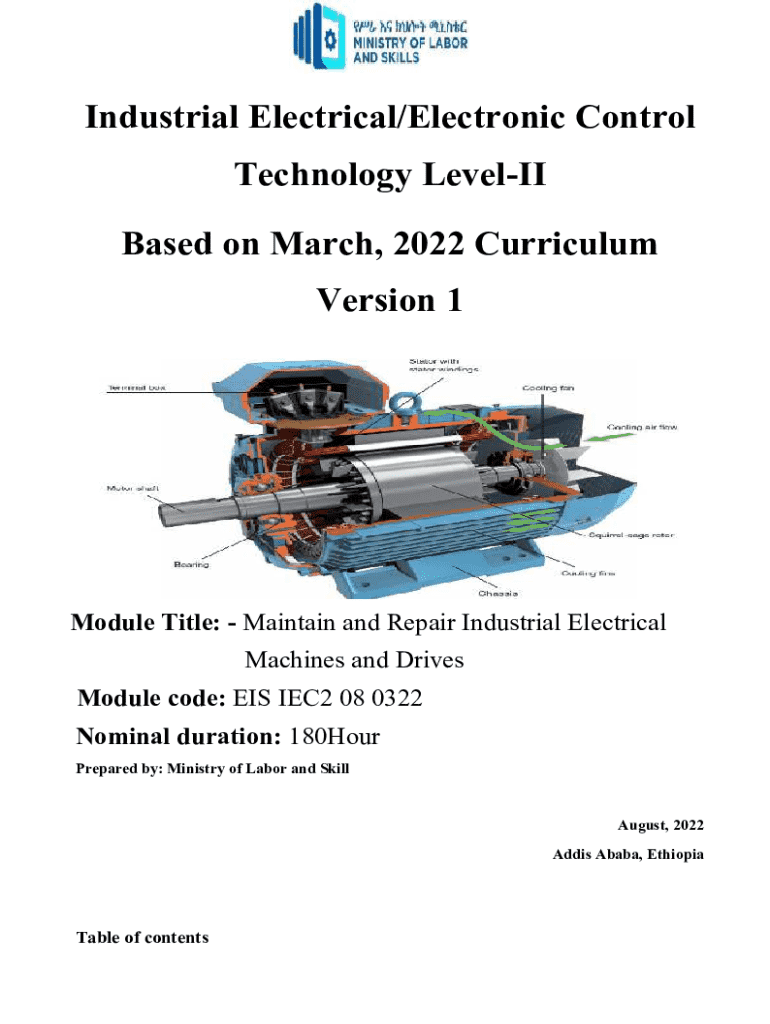

Industrial electrical/electronic control technology forms play a vital role in streamlining operations in various sectors, including manufacturing, energy, and automation. These forms standardize control processes, ensuring efficient communication and management of systems that depend on electrical and electronic controls.

Control technology encompasses a range of systems, from simple relay controls to complex programmable logic controllers (PLCs). Understanding the various types of control forms is crucial for engineers and operators alike, as they serve as blueprints for implementing control strategies that can greatly enhance productivity and safety.

The significance of using professional control forms

Using structured control technology forms brings multiple benefits to organizations. They not only enhance the accuracy of data collection but also foster improved communication among team members, ensuring everyone is on the same page regarding control processes.

Regulatory compliance is another critical reason to utilize professional control forms. Many industries are subject to regulatory standards that require documentation of procedures, which can be best met with well-designed control forms. For instance, the chemical manufacturing sector often relies on strict documentation to comply with safety regulations.

Consider a case study in an automotive manufacturing plant where the implementation of tailored control technology forms resulted in a 30% reduction in downtime due to improved documentation of control procedures. Such real-world examples underline the value of structured forms.

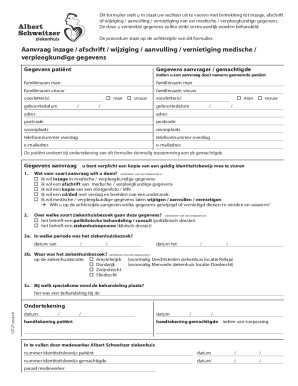

Components of an industrial control technology form

A comprehensive industrial control technology form consists of several essential components. The form identification helps categorize different forms, keeping the documentation organized. User information fields allow for easy tracing back to the individual responsible for the inputs, ensuring accountability.

Control specifications are crucial for detailing the specific requirements of a control process, including thresholds, acceptable limits, and system specifications. Additionally, optional sections can enhance the form's usability by including safety protocols and maintenance guidelines to ensure longevity and safety in operations.

Supplementing the essential elements with safety protocols can aid in compliance, as it ensures that all safety measures are documented and acknowledged. Maintenance guidelines help teams keep a check on system efficiency and prevent breakdowns.

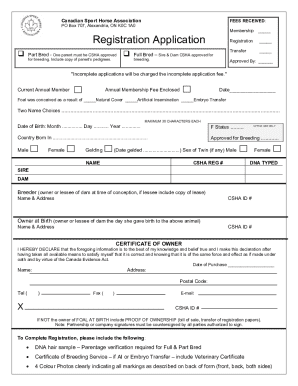

Steps for creating a comprehensive control technology form

Creating a comprehensive control technology form requires a systematic approach. The first step is identifying the purpose and scope of the form to ensure it meets its intended function. Gathering required information from stakeholders will provide the necessary foundation for the form.

Choosing the right format and software is crucial; tools like pdfFiller offer extensive capabilities for designing and managing forms efficiently. Designing the form layout is another essential step; it should adhere to visual hierarchy and user experience principles to enhance readability. Implementation of interactive features like checkboxes and dropdowns can also simplify the completion process.

Best practices for filling out industrial control technology forms

Filling out industrial control technology forms requires diligence to ensure accuracy and completeness. Users should always double-check the information entered, specifically focusing on critical control specifications and user fields. Utilizing pdfFiller can also simplify the process with its easy editing features.

Ensuring data security and privacy during submission is paramount. Secure platforms should be utilized to safeguard the sensitive information contained within these forms, helping to comply with regulatory criteria for data protection.

Strategies for reviewing and approving control forms

The review and approval process for control forms can benefit from collaborative techniques. Utilizing tools like pdfFiller, teams can work together in real-time to address corrections and feedback, which fosters a more efficient workflow.

Establishing checklists for final approval can streamline the process, ensuring that all necessary information is captured. Setting up approval chains within teams ensures that forms are reviewed by all relevant stakeholders before finalization.

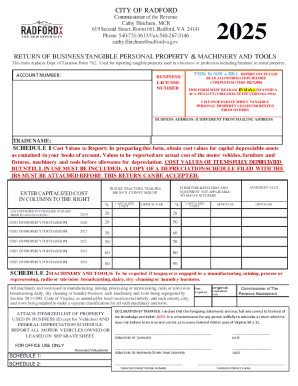

Managing control technology forms over time

Over time, managing control technology forms involves effective organization and storage. Employing a systematic approach ensures that forms are easily retrievable when needed. Using a platform like pdfFiller can enhance document management by allowing users to store all forms in one accessible location.

Version control and keeping track of document history is essential, particularly in industries subject to stringent audits. Compliance with the latest regulations must be ensured by regularly updating control forms to reflect changes in standards.

Common challenges and solutions in control form management

Common challenges in managing control technology forms include errors during completion and miscommunication between teams. Errors can arise from confusion over form requirements or incorrect entries, leading to ineffective control measures.

To mitigate these issues, utilizing a platform like pdfFiller addresses many common problems. Features such as pre-filled fields and clear instructions streamline the filling process and minimize errors, while collaboration tools prevent miscommunication in the review stages.

The future of industrial electrical/electronic control technology forms

As industries evolve, the landscape of industrial electrical/electronic control technology forms is bound to change. Innovations in document management software are paving the way for more intuitive and efficient forms. Enhanced automation and artificial intelligence capabilities are driving the need for smarter, more dynamic forms that respond to real-time data.

Trends such as cloud-based solutions will dominate the future, allowing for easier access to forms from any location. As automation becomes more prevalent, control forms will likely incorporate more context-sensitive elements, enhancing user interaction and overall effectiveness.

Interactive tools and resources available on pdfFiller

pdfFiller offers a suite of interactive tools designed to simplify the document creation process. Users can create, edit, and manage their industrial electrical/electronic control technology forms through an intuitive interface. Additionally, interactive tutorials help new users familiarize themselves with the platform's capabilities, making it accessible to everyone.

Community support and a knowledge base provide ongoing assistance and feedback, ensuring that users always have access to the help they need. The all-in-one platform empowers users to harness the full potential of their control technology forms.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an electronic signature for the industrial electricalelectronic control technology in Chrome?

How do I complete industrial electricalelectronic control technology on an iOS device?

How do I edit industrial electricalelectronic control technology on an Android device?

What is industrial electrical/electronic control technology?

Who is required to file industrial electrical/electronic control technology?

How to fill out industrial electrical/electronic control technology?

What is the purpose of industrial electrical/electronic control technology?

What information must be reported on industrial electrical/electronic control technology?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.