Get the free Methylene Diphenyl Diisocyanate (Monomer and Polymeric Forms ... - oehha ca

Get, Create, Make and Sign methylene diphenyl diisocyanate monomer

Editing methylene diphenyl diisocyanate monomer online

Uncompromising security for your PDF editing and eSignature needs

How to fill out methylene diphenyl diisocyanate monomer

How to fill out methylene diphenyl diisocyanate monomer

Who needs methylene diphenyl diisocyanate monomer?

Methylene Diphenyl Diisocyanate Monomer Form: A Comprehensive Guide

Overview of methylene diphenyl diisocyanate ()

Methylene diphenyl diisocyanate (MDI) is a highly versatile chemical compound predominantly used in the production of polyurethanes. Structurally, MDI consists of two isocyanate groups attached to diphenyl methane, visualized through its formula C15H10N2O2. This unique structure enables MDI to react readily with polyols, forming polyurethanes that are employed across various industries.

MDI is crucial in manufacturing high-performance materials because of its excellent thermal stability and mechanical strength. These properties make MDI indispensable in applications ranging from insulation to automotive manufacturing.

Applications of in various industries

MDI finds applications in multiple sectors due to its unique properties. Its ability to form stable polymers makes it a preferred choice in the production of various commercial products.

Construction industry

In the construction industry, MDI is extensively used in insulation materials like spray foam. These materials not only offer excellent thermal insulation properties but also contribute significantly to energy efficiency in buildings, leading to lower energy consumption.

Automotive industry

MDI plays a vital role in the automotive sector, particularly in manufacturing vehicle components, including dashboards, seat cushions, and insulation materials. The durability and performance enhancements provided by MDI-based materials contribute significantly to the overall longevity and safety of vehicles.

Furniture and bedding

MDI is heavily utilized in producing flexible foams for furniture and bedding products. These foams meet health and safety regulations, providing comfortable and supportive surfaces while ensuring consumer safety. The foam’s resilience and longevity make it a popular choice among manufacturers.

Understanding the monomer form

The MDI monomer form refers to the pure isocyanate utilized in polymerization processes. Unlike its polymerized counterpart, the monomer form possesses reactive isocyanate groups that readily participate in chemical reactions to create various polyurethane materials. This makes the monomer form essential for the initial stages of production.

Comparison with other isocyanates

MDI is often compared to Toluene Diisocyanate (TDI), another popular isocyanate used in the production of polyurethanes. MDI is generally favored for applications requiring more robust materials due to its higher molecular weight. While both compounds serve similar purposes, MDI offers superior thermal stability and mechanical properties.

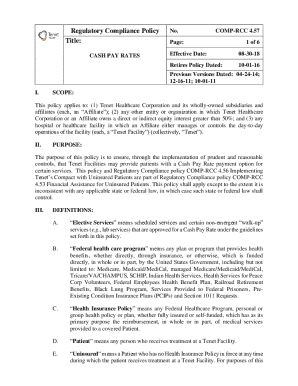

Safety and handling of

Safety is a paramount concern when handling MDI, given its reactive nature. Proper precautions must be taken to minimize exposure risks, including using appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators. Ensuring adequate ventilation in work areas is also critical.

Safety precautions

Environmental considerations

MDI has implications for the environment, particularly concerning its production processes and potential for atmospheric emissions. Manufacturers are encouraged to implement mitigation strategies to minimize environmental impacts, such as using closed systems and emission controls during production.

Filling out the monomer form: step-by-step

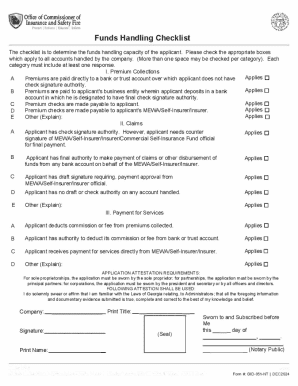

Completing the MDI monomer form is vital for compliance and safe usage. This section provides a systematic approach to filling out this form, ensuring that users have all necessary details on hand.

Gathering required information

Completing the form

When completing the form, ensure meticulous attention to detail. Here is a breakdown of the relevant sections:

Common mistakes to avoid

Accuracy is essential when submitting the MDI monomer form. Common pitfalls include incomplete information, incorrect product specifications, and failure to attach safety documents. To ensure successful submission, double-check all entries and mandatory attachments.

Editing and managing your monomer form

Once the MDI monomer form has been filled out, utilizing editing tools can streamline the management process. pdfFiller provides robust solutions for editing and signing documents online, enhancing your workflow.

Utilizing pdfFiller’s tools

Storing and sharing your document

Securely storing your completed documents is essential. pdfFiller allows users to save documents in the cloud, facilitating easy access and sharing. With permission features, team members and stakeholders can collaborate seamlessly.

FAQs about methylene diphenyl diisocyanate monomer form

Many users have questions regarding the usage and applications of MDI, especially in relation to safety and regulatory compliance. Here are some common inquiries addressed for clarity:

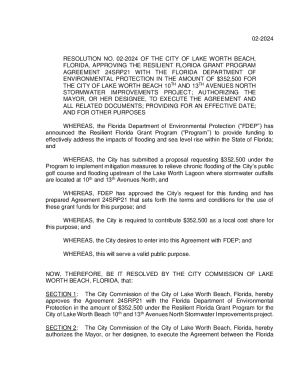

Interactive tools for form management

pdfFiller offers interactive features that enhance the MDI form management experience. Users can utilize tools for tracking document statuses and controlling versions, ensuring efficient workflow management.

Testimonials from users

Industries leveraging MDI have found significant advantages in their operations. Case studies showcase how investments in MDI have led to improved product quality and operational efficiency.

Future trends in applications

As technology evolves, the applications of MDI are set to expand. Innovations in sustainable production and enhanced formulation techniques promise to broaden the scope and efficiency of MDI in manufacturing.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute methylene diphenyl diisocyanate monomer online?

How do I edit methylene diphenyl diisocyanate monomer online?

How do I make edits in methylene diphenyl diisocyanate monomer without leaving Chrome?

What is methylene diphenyl diisocyanate monomer?

Who is required to file methylene diphenyl diisocyanate monomer?

How to fill out methylene diphenyl diisocyanate monomer?

What is the purpose of methylene diphenyl diisocyanate monomer?

What information must be reported on methylene diphenyl diisocyanate monomer?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.