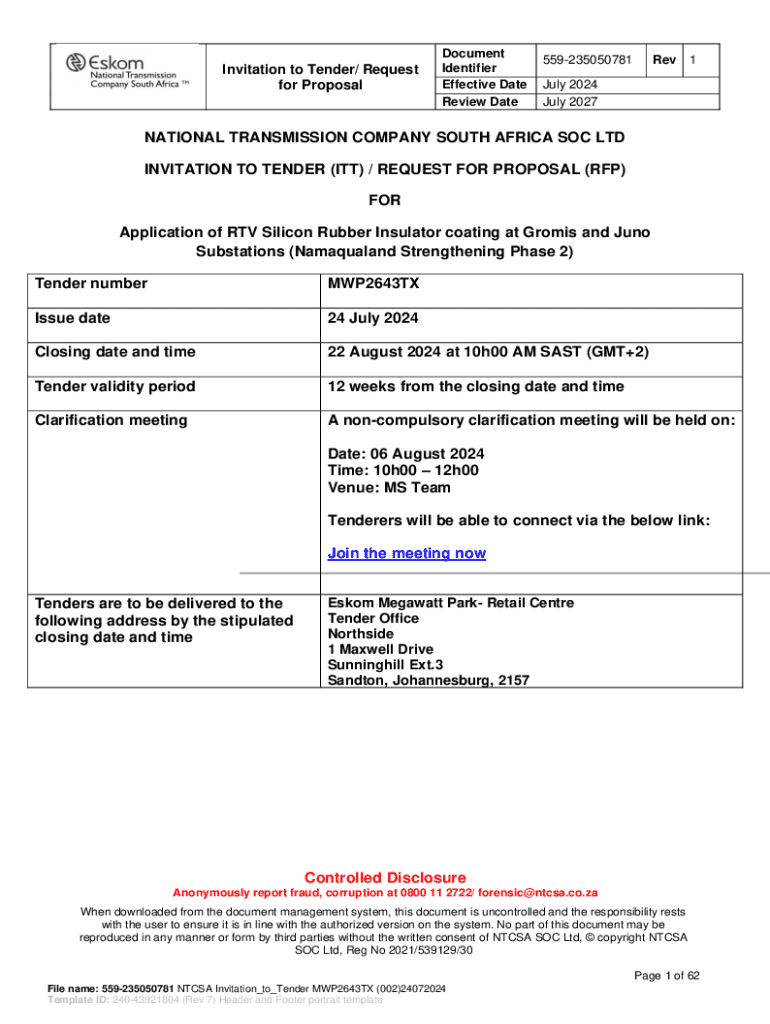

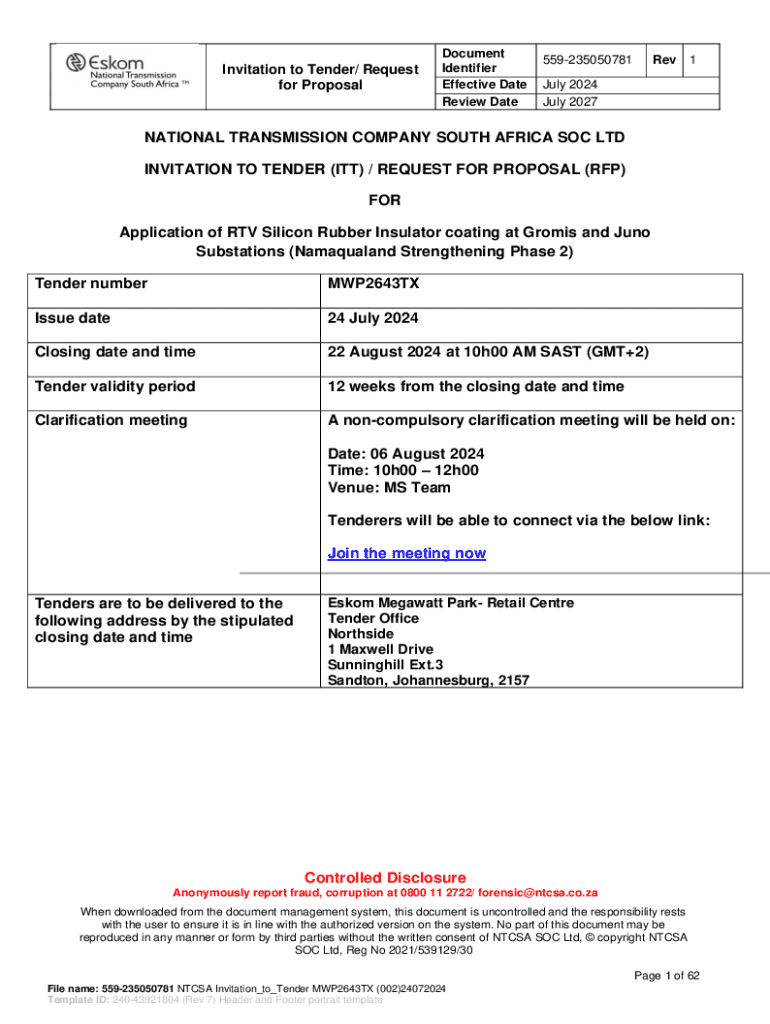

Get the free Application of RTV Silicon Rubber Insulator coating at Gromis and Juno

Get, Create, Make and Sign application of rtv silicon

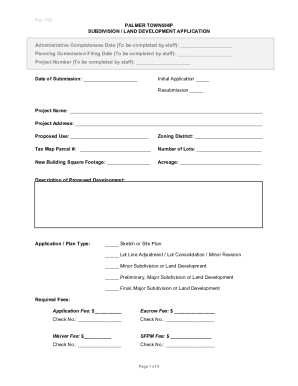

How to edit application of rtv silicon online

Uncompromising security for your PDF editing and eSignature needs

How to fill out application of rtv silicon

How to fill out application of rtv silicon

Who needs application of rtv silicon?

Application of RTV Silicone Form

Understanding RTV silicone forms

RTV (Room Temperature Vulcanizing) silicone is a versatile and highly useful material in various industries. It is designed to cure at room temperature, forming a flexible, durable, and weather-resistant silicone rubber. This characteristic makes RTV silicone an ideal choice for applications that require reliable sealing, bonding, and molding. The importance of RTV silicone can be observed across different sectors where flexibility and resilience are paramount.

In addition to its adaptability, RTV silicone possesses key properties that include excellent temperature resistance, chemical stability, and strong adhesion capabilities. These features contribute significantly to its widespread use in automotive, medical, construction, and electronic applications, influencing its demand in the marketplace. Understanding these properties allows users to select the appropriate RTV silicone product tailored to specific project needs.

Key features and benefits of RTV silicone

RTV silicone stands out for several key features that enhance its functionality and usability in numerous applications. Each of these benefits significantly influences project outcomes, making RTV silicone a preferred choice in various scenarios.

Primary applications of RTV silicone forms

RTV silicone forms have found diverse applications across multiple industries, often driven by the need for reliable sealing and bonding solutions.

How to effectively utilize RTV silicone forms

To harness the full potential of RTV silicone, proper utilization is essential. This involves careful preparation, application techniques, and troubleshooting.

Preparation before application

Begin with a clean surface. Ensure that the areas to be bonded or sealed are free from dust, oil, and moisture as these contaminants can hinder adhesion. Additionally, choose the right RTV silicone product by considering factors such as temperature resistance and curing time, as these will impact performance.

Step-by-step guide for application

Troubleshooting common issues

Common issues such as adhesion failure or improper curing can occur. To troubleshoot, verify that surface preparation was thorough and that the RTV silicone was applied within the recommended conditions. Solutions may include reapplying after proper surface cleaning or selecting a more suitable product for your specific environment.

Innovations and future trends in RTV silicone

The evolution of RTV silicone is marked by ongoing innovations. Emerging technologies in silicone formulations are improving performance characteristics such as heat tolerance and chemical resistance. Furthermore, there is a growing demand for eco-friendly RTV silicone products that minimize environmental impact, which will shape future developments in the market.

As industries continue to embrace sustainable practices, RTV silicone manufacturers are likely to explore bio-based materials and processes that cater to these changes. Market growth is anticipated as new applications for RTV silicone emerge, fueled by technological advancements and the drive for efficiency.

Best practices for storing and handling RTV silicone

To maintain the integrity of RTV silicone products, proper storage and handling are crucial. Store RTV silicone in a cool, dry place, avoiding direct sunlight and high humidity to extend shelf life.

During handling, take safety precautions such as wearing gloves, particularly if working with bulk or uncured silicone. Always check shelf life and use products before their expiration to ensure optimal performance.

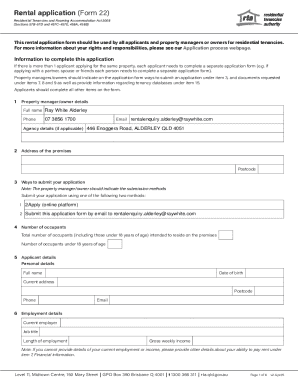

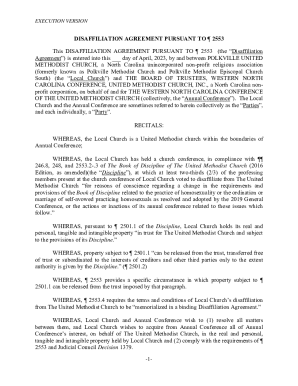

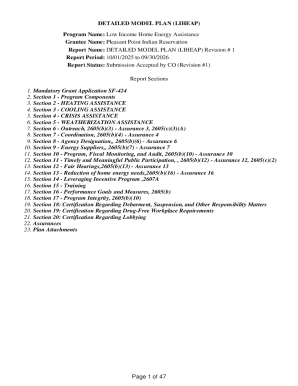

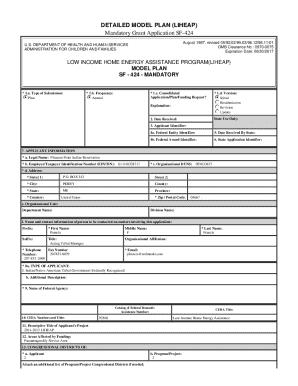

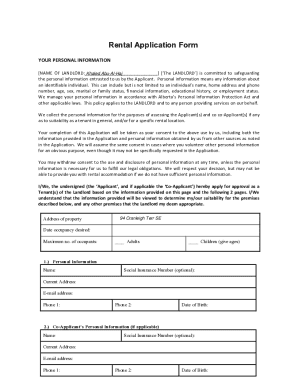

Interactive tools for managing RTV silicone forms

Utilizing digital tools can significantly enhance the management of RTV silicone forms. Solutions such as pdfFiller provide an efficient platform for creating, editing, and signing documents related to RTV silicone applications. This allows teams to streamline their projects and collaborate effectively, ensuring that documentation is accessible and up-to-date.

The benefits of using pdfFiller extend to interactive document management, making it easier to fill out forms and track changes. With features that support online editing and e-signatures, users can efficiently manage RTV silicone-related forms from anywhere, fostering productivity in both individual and team settings.

Case studies and success stories

Examining case studies reveals how companies have successfully implemented RTV silicone in their operations. One notable instance involves an automotive manufacturer that integrated RTV silicone seals into its engine designs, achieving a 25% reduction in assembly time and improving vehicle durability. The use of RTV silicone helped address critical seal integrity issues that affected performance and customer satisfaction.

Client testimonials consistently highlight the effectiveness of RTV silicone solutions in providing reliable seals and bonds across varied applications. Users commend its ease of application, impressive performance, and long-term reliability. These success stories illustrate the transformative impact of utilizing RTV silicone in critical applications.

Comparative analysis with other sealants

When comparing RTV silicone with alternative sealants, several factors must be considered. RTV silicone often outperforms traditional materials, such as rubber and polyurethane, due to its superior flexibility, chemical resistance, and temperature tolerance.

Understanding the nuances of other sealing options will help determine when to choose RTV silicone. For scenarios involving high temperatures, chemical environments, and where flexibility is essential, RTV silicone typically stands out as the preferred solution.

Customizing RTV silicone forms for your specific needs

Customization is often necessary to meet unique project requirements. Users can tweak RTV silicone applications by selecting specific formulations tailored for particular conditions or by altering application techniques to optimize fit and function.

Collaboration tools, such as those available through pdfFiller, allow teams to align on project specifications, ensuring that everyone is on the same page regarding customization needs. Using pdfFiller's features for editing and signing forms further streamlines the customization process, enhancing efficiency.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit application of rtv silicon from Google Drive?

How can I get application of rtv silicon?

How do I make changes in application of rtv silicon?

What is application of rtv silicon?

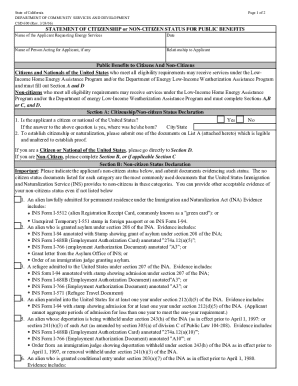

Who is required to file application of rtv silicon?

How to fill out application of rtv silicon?

What is the purpose of application of rtv silicon?

What information must be reported on application of rtv silicon?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.